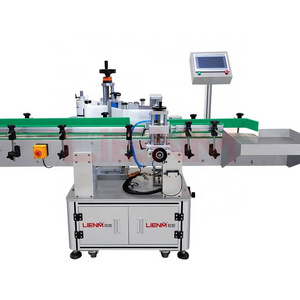

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380V, 50/60hz, 220v/380v,56/60HZ

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

BRICSPACK

-

Dimension(L*W*H):

-

2200*1300*1200MM

-

Weight:

-

800KG

-

Machinery Capacity:

-

5000-6000BPH

-

Usage:

-

Stick Label Automaticlly

-

Labeling Accuracy:

-

In+-0.5mm

-

Label size:

-

Max L330mm, Max W170mm

-

Bottle type:

-

Round Bottle Jars Cans

-

Bottle Material:

-

PET, GLASS, Plastic

-

Labeling speed:

-

2000-6000BPH

-

Label material:

-

OPP

-

Label thickness:

-

0.03-0.13mm

-

Power supply:

-

7kw

-

Certification:

-

CE

Quick Details

-

Application:

-

Food, Beverage, Commodity, Medical, Chemical, Machinery & Hardware

-

Packaging Type:

-

case

-

Packaging Material:

-

Wood

-

Voltage:

-

220/380V, 50/60hz, 220v/380v,56/60HZ

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

BRICSPACK

-

Dimension(L*W*H):

-

2200*1300*1200MM

-

Weight:

-

800KG

-

Machinery Capacity:

-

5000-6000BPH

-

Usage:

-

Stick Label Automaticlly

-

Labeling Accuracy:

-

In+-0.5mm

-

Label size:

-

Max L330mm, Max W170mm

-

Bottle type:

-

Round Bottle Jars Cans

-

Bottle Material:

-

PET, GLASS, Plastic

-

Labeling speed:

-

2000-6000BPH

-

Label material:

-

OPP

-

Label thickness:

-

0.03-0.13mm

-

Power supply:

-

7kw

-

Certification:

-

CE

Product Description

Applcation

Automatic Hot melt glue labeling machine, it is widely used for different material of bottles, cans, jars and so on. The label

cost is comparatively lower, the machine can meet requirements of those users who have variety of containers. It is most

economical models on cost to make mass production.

The equipment has massive modularization design concept to make it easy and simple to change bottles. Whether from the replacement

of star wheel, guide plate or manual speed adjustment to automatic speed control, changing the label is only needed to change the

program, the machine is embodies the concept that it is used for users and considered for everywhere.

cost is comparatively lower, the machine can meet requirements of those users who have variety of containers. It is most

economical models on cost to make mass production.

The equipment has massive modularization design concept to make it easy and simple to change bottles. Whether from the replacement

of star wheel, guide plate or manual speed adjustment to automatic speed control, changing the label is only needed to change the

program, the machine is embodies the concept that it is used for users and considered for everywhere.

Detailed Images

Label station

Consist of label identification and label feeding, photo sensor identify the i-mark on the label, to convey the label to label gluing and cutting zone by servo motor's acceleration and deceleration action.

Label guide group

-

Labeling drum

The label from label guide pillar send to glue box group, hot melt glue will be smeared on the end of label by glue roller. Then will be cutting by cutter. At last, by rolling on the bottle, finshed.

The labeling drum have a fan control to make labels attach the drum working station.

Glue box and Glue roller

Cutter

Star wheel

For seperating and conveying bottle, keep bottle in the same interval, and making stable transimission for bottles.

Bottle rubbing group

Label has been smeared glue and then meet the bottle, with the rolling and rubbing, make the label attached on the bottle more stable.

Size Information

|

Model

|

QB-HL100

|

|

Capacity

|

2000-6000BPH

|

|

Label size

|

125mm-450mm

|

|

Label thickness

|

0.028-0.05mm

|

|

Label reel core diameter

|

150mm (125mm as option)

|

|

Label reel diameter

|

500mm

|

|

Label material

|

OPP, BOPP

|

|

Container material

|

PE, PET , GLASS, BOTTLE

|

|

Power

|

380Volts, 3 ohase, 50-60Hz, 5Kw

|

|

Air consumption

|

8L/min (6Kg/Cm²)

|

|

Weight

|

800kg

|

|

Machine size

|

2200mm*1500*1300mm

|

Packaging and shipping

Customer Visiting

Company Introduction

We, Shanghai Bricspack Automation Technology Co., Ltd

is a professional manufacturer of LABELING MACHINE for bottles

Our mainly products are following:

1.PVC shrink sleeve labeling machine;

2. OPP hot melt glue labeling mahcine;

3. Wet glue paper labeling machine;

4. Self-Adhesive labeling machine;

Our machine widly used in such industries as foodstuff, beverage and cosmetics, (fruit juice, tea drinks, dairy product,

purified water, condiments, beer, sport drinks and cosmetics etc of various bottle types.)

Looking forward to your kindly reply so that We can provide you the suitable solution with right labeling machine.

Hope we have an opportunity to cooperate with you and provide you our best service with high quality labeling machinery.

Our mainly products are following:

1.PVC shrink sleeve labeling machine;

2. OPP hot melt glue labeling mahcine;

3. Wet glue paper labeling machine;

4. Self-Adhesive labeling machine;

Our machine widly used in such industries as foodstuff, beverage and cosmetics, (fruit juice, tea drinks, dairy product,

purified water, condiments, beer, sport drinks and cosmetics etc of various bottle types.)

Looking forward to your kindly reply so that We can provide you the suitable solution with right labeling machine.

Hope we have an opportunity to cooperate with you and provide you our best service with high quality labeling machinery.

After Sales Service

1. Specialized department and management personnel responsible for after services, large amounts of parts and fittings areavailable;

2. Senior after-service engineers of our company will offer you regular technical services;

3. Complete after-service system and outstanding quality assure you of satisfaction and easement.

4. One year warranty.

2. Senior after-service engineers of our company will offer you regular technical services;

3. Complete after-service system and outstanding quality assure you of satisfaction and easement.

4. One year warranty.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

* Engineers available to service machinery overseas.

FAQ

1.Question: What's your main products?

Reply: we produce Sleeve labeling machine, Adhesive sticker labeling machine, OPP Hot melt glue labeling machine etc.

2.Question: Are you factory?

Reply: Yes, Our factory located in No.5 huasheng east road, zhoushi town, kushan city, Jiangsu province, China.

Shanghai Office address: 777 Fuhai Road, Jiading Industrial area, Jiading District, Shanghai, China.

3.Question: If I have special needs about design about the bottle label and machine,can you do that for me?

Reply: We have the professional designers, can design under your needs, based on the bottle/label sample, we also can supply plant

engineering service for you;

4.Question:How about your after-sale service?

Reply: we have professional technical department to ensure the machine functioning well, both hardware and software technology;

5.Question: How long about the delivery time?

Reply: When we get your advance deposit, and your bottle&label samples, it about 20 days.

Reply: we produce Sleeve labeling machine, Adhesive sticker labeling machine, OPP Hot melt glue labeling machine etc.

2.Question: Are you factory?

Reply: Yes, Our factory located in No.5 huasheng east road, zhoushi town, kushan city, Jiangsu province, China.

Shanghai Office address: 777 Fuhai Road, Jiading Industrial area, Jiading District, Shanghai, China.

3.Question: If I have special needs about design about the bottle label and machine,can you do that for me?

Reply: We have the professional designers, can design under your needs, based on the bottle/label sample, we also can supply plant

engineering service for you;

4.Question:How about your after-sale service?

Reply: we have professional technical department to ensure the machine functioning well, both hardware and software technology;

5.Question: How long about the delivery time?

Reply: When we get your advance deposit, and your bottle&label samples, it about 20 days.

Hot Searches