- Product Details

- {{item.text}}

Quick Details

-

Use:

-

Industrial

-

Place of Origin:

-

Quang Nam, Vietnam

-

Model Number:

-

Warehouse Storage Powder Coating Steel Platform

-

Depth:

-

1.5-3.0mm

-

Weight Capacity:

-

100Kgs/square meter - 1000Kgs/square meter

-

Width:

-

1000-4000mm

-

Height:

-

1500mm-6000mm

-

Surface Treatment:

-

Powder Coating/ Galvanizing

-

Material Condition:

-

GB-T Q235, Q345 High Class Carbon Steel

-

Upright Column Type:

-

pe: Structural H Steel, Round Tubing, Roll-formed Post

-

Beam Type:

-

Structural H Steel, Interlock Beam

-

Floor Type:

-

Interlock Powder Coated / Grating Galvanized

-

Characteristics:

-

Anti-seismic, Industrial Safety Class

-

Components:

-

Staircase, Handrail, Guardrail, Accessing Gate, Wire Fence

-

Back-up Services:

-

Installation Drawing/ On Site Instruction

-

Design Services:

-

Available

-

Certification:

-

CE

Quick Details

-

Type:

-

Multi-Level

-

Material:

-

Steel

-

Feature:

-

Corrosion Protection

-

Use:

-

Industrial

-

Place of Origin:

-

Quang Nam, Vietnam

-

Model Number:

-

Warehouse Storage Powder Coating Steel Platform

-

Depth:

-

1.5-3.0mm

-

Weight Capacity:

-

100Kgs/square meter - 1000Kgs/square meter

-

Width:

-

1000-4000mm

-

Height:

-

1500mm-6000mm

-

Surface Treatment:

-

Powder Coating/ Galvanizing

-

Material Condition:

-

GB-T Q235, Q345 High Class Carbon Steel

-

Upright Column Type:

-

pe: Structural H Steel, Round Tubing, Roll-formed Post

-

Beam Type:

-

Structural H Steel, Interlock Beam

-

Floor Type:

-

Interlock Powder Coated / Grating Galvanized

-

Characteristics:

-

Anti-seismic, Industrial Safety Class

-

Components:

-

Staircase, Handrail, Guardrail, Accessing Gate, Wire Fence

-

Back-up Services:

-

Installation Drawing/ On Site Instruction

-

Design Services:

-

Available

-

Certification:

-

CE

Warehouse Storage Powder Coating Steel Platform

Brief Introduction

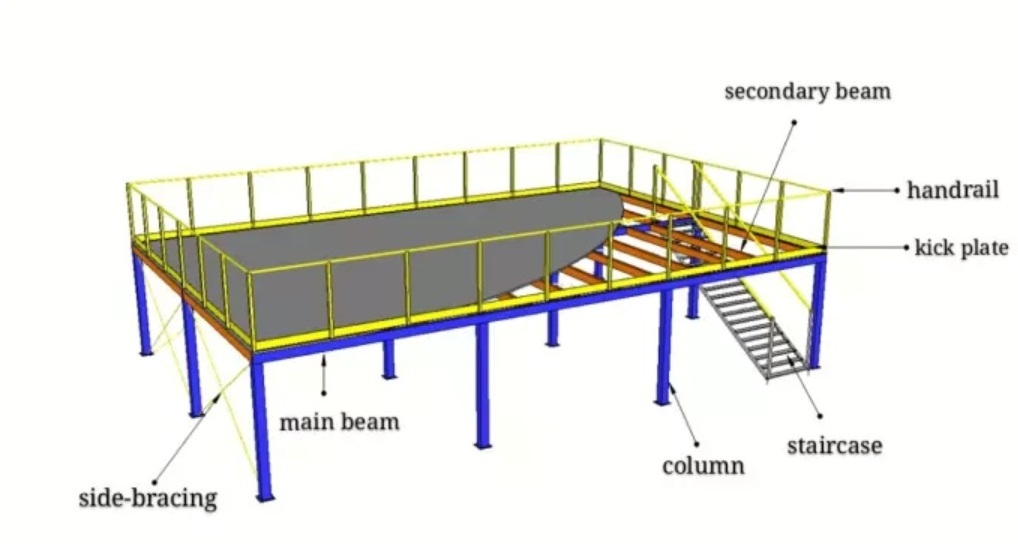

The steel platform is mainly composed of column, main beam, secondary beam, flooring, staircase and handrail. It is overall assembly and no need welding. The structure is strong and different flooring can be selected according to the actual needs to meet the requirements of fire protection, dust prevention and small parts falling. The lighting system can also be configured under the floor.

Features and Advantages

· Improving storage height and increasing space utilization rate

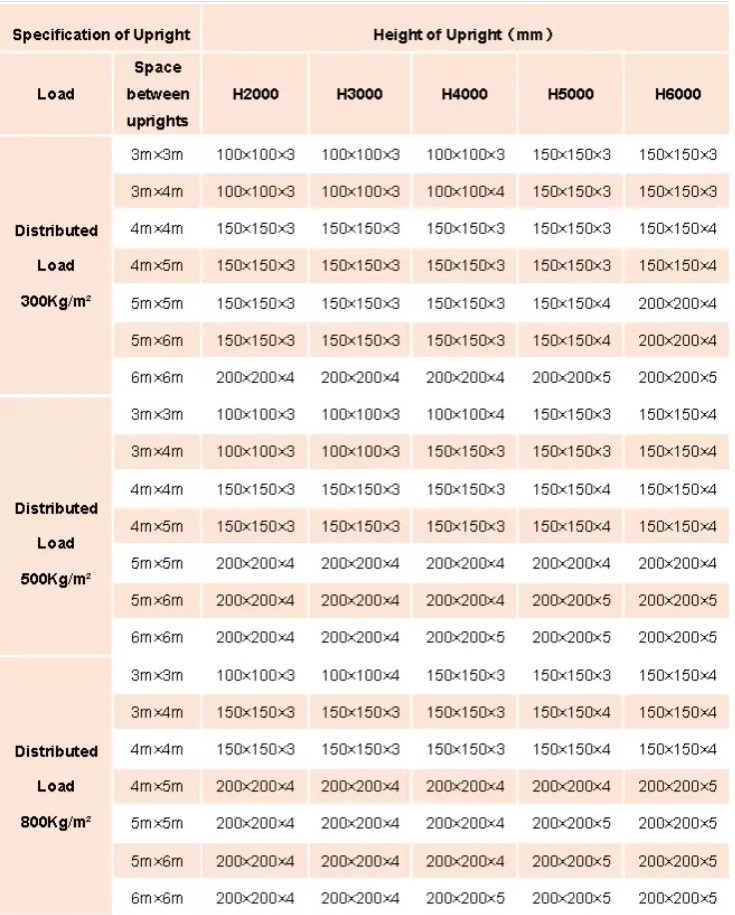

· The space between uprights is usually from 4m to 6m.

· Wide range of applicability, combined with shelving storage features.

· The loading capacity is 200kg to 1000kg/m².

· The goods can be transported by hydraulic lifting platform, cargo lift or forklift.

Column

Material and size

|

Conventional upright material |

Size |

|

100*100 , 150*150 , 200*200 |

|

|

H-shaped steel |

H150*150 , H200*200 , H250*250 |

Model selection

Main beam and secondary beam

|

Conventional material |

Size |

|

H-shaped steel |

H150*75, H175*90 and others |

|

M-shaped steel |

200*65* ( 2 , 2.5 , 3 ), 250*68 , 300*65 |

Floor

Steel floors are the necessary part for the steel platform racking system. With the comprehensive engineering design and on site analysis and installation experience, BHD Racking Vietnam Factory developed its unique functional and practical steel floors.

Loading door

BHD Racking Vietnam Factory designs the size of the loa ding door according to the size of the goods.

Staircase

The angle of standard staircase is 38°to 42°.The floor height exceeds 4m, which shall be divided into 2 groups of stairs plus 1 group of stairs platform.

Stair & Handrail Specifications

Handrail Notes:

1. Handrails shall be continuous on at least one side of stairs with 4 or more risers.

2. Top of the handrails shall be placed not less than 34 inches nor more than 38 inches above stair nosings.

3. The handgrip portion of handrails shall be not less than 1-1/4 inches nor more than 2 1/4 inches in circular cross section.

4. Handrails shall be placed not less than 1-1/2 inches from any wall or other surface.

5. Handrails to be returned to wall. post or safty terminal (per CRC R311.7.8.2)

Acceptable Handrail Details

Unacceptable Handrails

Applications

Projects Reference

Factory

Official website of Vietnam factory

Geographical position

Da Nang Port

• Third Largest Port System in Central Vietnam

• Lies at one end of the East–West Economic Corridor.

• Authority Shipping Line: Vietnam National Shipping Lines (Vinalines)

As being located near the third largest trading port in Vietnam which has the direct shipping lane, BHD Racking Vietnam Factory believes your orders will be delivered in the short time.

Shipment

|

Item |

Loading Port |

Destination Port |

Period |

|

1 |

Da Nang Port |

Long Beach Port |

20 days |

|

2 |

Da Nang Port |

Houston Port |

35 days |

|

3 |

Da Nang Port |

Miami Port |

40 days |

|

4 |

Da Nang Port |

New York Port |

45 days |

Factory capacity

BHD Racking Vietnam Factory delivers 80 containers per month. After receiving the order, production can be completed in 20 days.

Advantage

No Import Duty to U.S.A.,COO can be provided

No Anti-dumping & Anti-subsidy Margin for Rack

Lower Labor Cost

USA Production – Shorter Production Time

Port city – Da Nang: 45min Drive

Direct Shipping Lane: Da Nang Port to Long Beach & Los Angeles Port

Packing

With Costomers

FAQ:

Q1: What is delivery time of your Vietnam factory?

A1: It depends on your volume. Normally our delivery time is 25 days. But when volume is large, please communicate with our sales rep so as to arrange a quickest delivery time.

Q2: What is your production capacity of Vietnam factory?

A2: 80 containers per month.

Q3: Are there any tariff or duties on your products to the United States or Australia?

A3: We have CO (Certificate of origin) from Vietnam. So there are no tariffs or duties.

Q4: Has your factory just been built or completed?

A4: Our factory has been completed as a whole in May 2019. You can see all the equipment and facilities in FACTORY part of website navigation. We sincerely welcome you to visit our factory.

Q5: What are the international trading terms provided?

A5: EXW / FOB / CIF / DDU. In fact, we can do all the international trading terms.

Q6: Do you have any certificate of products in Australia?

A6: We have AS-4084 certificate of Australia. We have valid

certificates required by the local market.

Q7: What are the payment terms?

A7: Generally our payment terms are 30% T/T in advance as deposit, 70% T/T against copy of B/L as balance. If you have any special requirements, please contact our sales rep directly.

Q8: How is the packaging of your products?

A8: Corrugated paper, carton box, crosstie, pallet, angle steel, plastic film, steel tie and air bag are used for proper packaging. All our products are packaged for export, so we have rich experience in export packaging.