- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v

-

Place of Origin:

-

China

-

Brand Name:

-

OEM

-

Dimension(L*W*H):

-

2.4x1.8x1.55m

-

Weight (KG):

-

1000

-

Warranty:

-

1 year

-

Production capacity:

-

60-80bottles/min

-

Structure:

-

8 liquid filling heads

-

Power supply:

-

220V 50Hz

-

Total power:

-

3KW

-

Weight:

-

1000kgs

-

Application:

-

Filling mosquito liquid, perfume or any liquid

Quick Details

-

Production Capacity:

-

60-80bottles/min

-

Automatic Grade:

-

automatic

-

Driven Type:

-

electric

-

Voltage:

-

220v

-

Place of Origin:

-

China

-

Brand Name:

-

OEM

-

Dimension(L*W*H):

-

2.4x1.8x1.55m

-

Weight (KG):

-

1000

-

Warranty:

-

1 year

-

Production capacity:

-

60-80bottles/min

-

Structure:

-

8 liquid filling heads

-

Power supply:

-

220V 50Hz

-

Total power:

-

3KW

-

Weight:

-

1000kgs

-

Application:

-

Filling mosquito liquid, perfume or any liquid

Products Description

|

Item

|

Automatic mosquito liquid filling machine (8 filling heads)

|

|

Material

|

Stainless steel 304

|

|

Filling speed

|

60-80 bottles/min

|

|

Power supply

|

220V 50Hz

|

|

Total power

|

3KW

|

|

Atmospheric pressure

|

0.5-0.8mpa

|

|

Air consumption

|

12-15m3/h

|

|

Dimension

|

2.4x1.8x1.55m

|

|

Weight

|

1000KGS

|

|

Structure

|

1 bottle scrambler+8 liquid filling heads+1 assembling machine for wick & stopper+1 wick & stopper placing pump+1 cap placing pump+1 capping pump

|

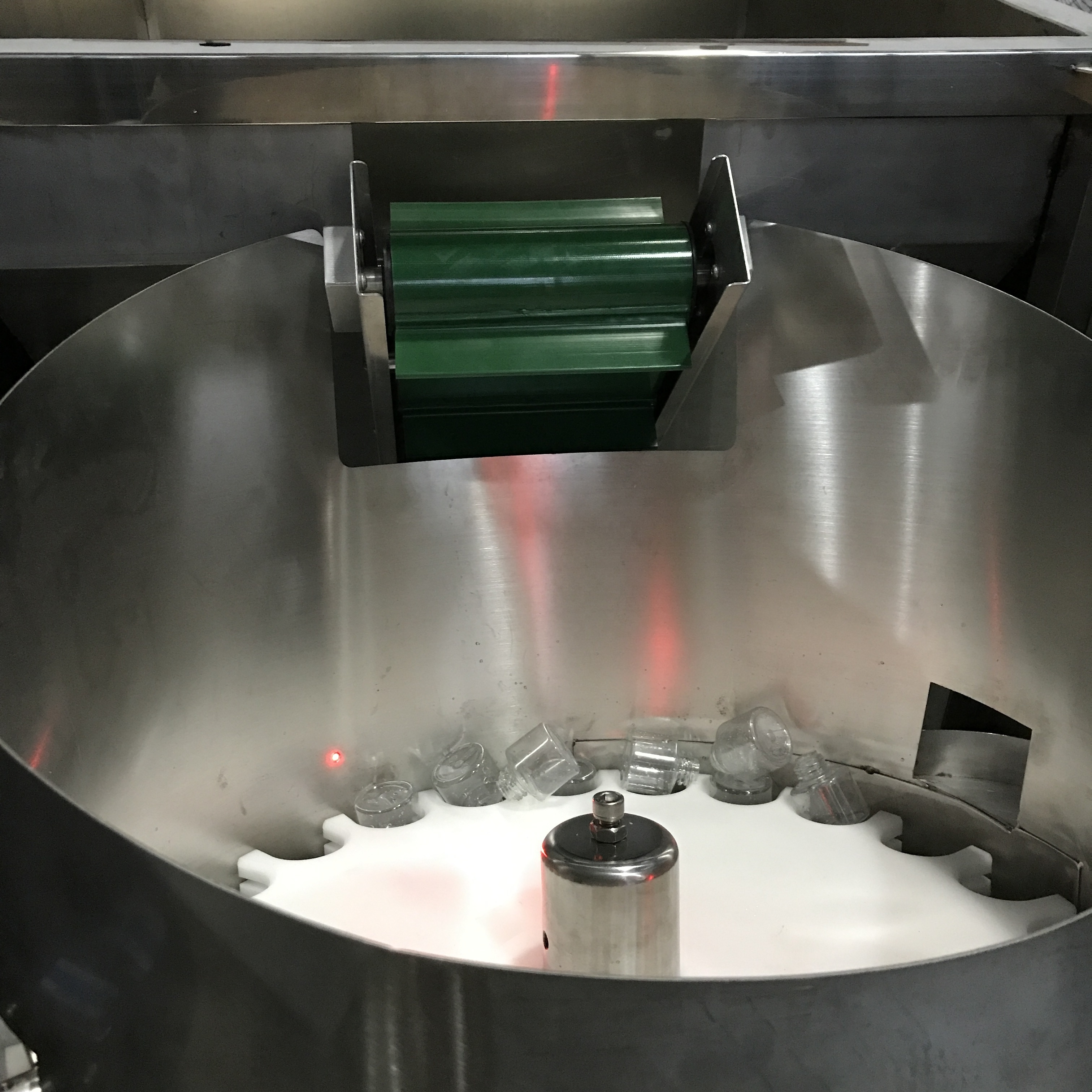

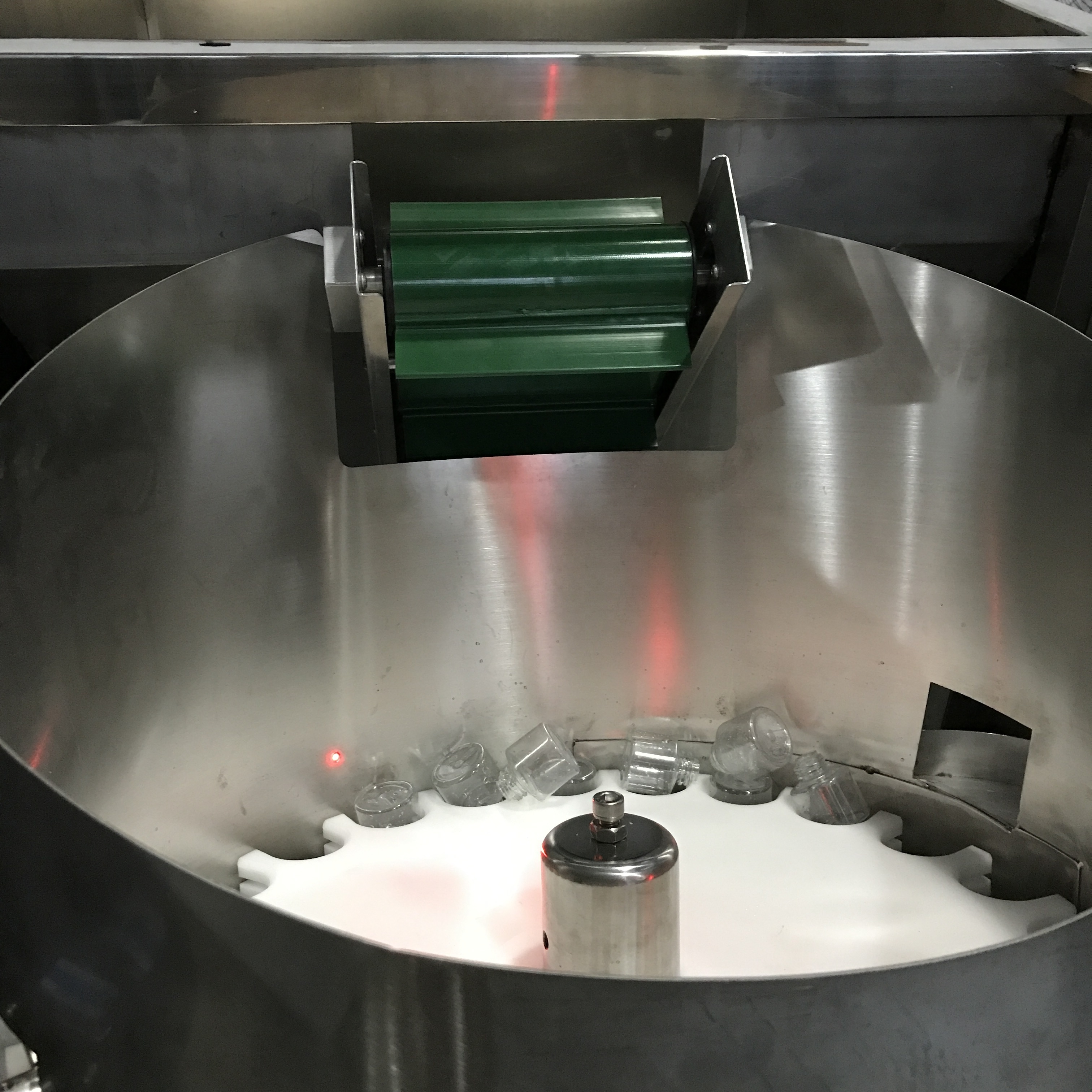

Bottle unscrambler

Bottles are placed in good order automatically by bottle unscrambler, and transported to the filling workshop through the conveyor belt and intercepted by the cylinder at the filling position

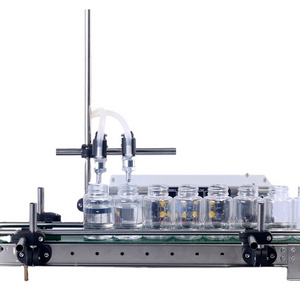

Filling heads

The filling heads of the supporting connecting rod is a 316L stainless steel pump, controlled by PLC with high filling accuracy. It is convenient to adjust the filling range. This machine adopts oil-free bearings from Germany, no need to add oil lubrication, no oil pollution, high wear resistance.

Servo positioning system

Filling is driven by servo motor, no bottles no filling. F

illing head automatically rises with the increase of the liquid. It doesn't touch the material. Equipment stops working if no bottles. After filling, the intercepting cylinder automatically releases, transports

the bottle to the disk work position, enters the next process.

the bottle to the disk work position, enters the next process.

Press plug into bottle

The plug plate is inserted into the plug position through vibration, and the filled bottle is intermittently transmitted from the positioning disk. Plugs are clip up by vacuum suction plug and turn to plug pressing process. The bottle with plug is then transported from the positioning disk into the conveyor belt and into the next process.

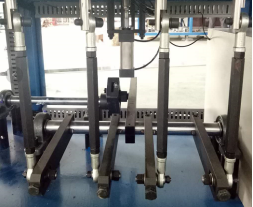

Plugging wick into stopper

Wicks are transported by the roller and inserted into stopper actomatically.

Capping

Caps are flew down to the assembled bottle and stopper. The screw head is driven downward by the lift shaft, while the three grip hands tighten and seize the cap rotation,thus playing a role in tightening the cap. The screw head is with magnetic force. After the cap is tightened, the cap is automatically skid to prevent the cover surface from being worn.

Recommend Products

Semi-automatic liquid filling machine

Roll to roll label cutting machine

Labeling and coding machine

Mosquito wick plugging machine

Manual paste filling machine

Mosquito mat packing machine

Bottle screen printing machine

Servo-driven screen printing machine

Shrinking and packing machine

Our factory

Our factory was set up in 2010, has 3 class 100,000 purification workshops, which reach the ISO9001 standard. We are equiped with advanced equipments and acomplete set of quality testing equipment, so as to guarantee the stable quality of all products.

Customer Photos

Exhibition

Hot Searches