- Product Details

- {{item.text}}

Quick Details

-

Heating Power (kW):

-

17 kW

-

Production Speed(times/h):

-

300

-

Power Supply:

-

380 V,3 phase,50/60HZ

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Looker

-

Voltage:

-

AC380V

-

Dimension(L*W*H):

-

2620*2020*2050mm

-

Weight (T):

-

0.7 T

-

Production efficiency:

-

50~300 cycles per hour

-

Twice vacuum suction:

-

Yes

-

Heater:

-

Infrared Ceramic

-

Max forming Height:

-

150mm

-

Power(W):

-

17KW

-

Suitable material:

-

PVC,PP,PS,PC,PET,ABS etc.

-

Application:

-

food box,medical packing,toys,stationery packing

-

Material Thickness:

-

0.2~1.5mm

-

Automatic Grade:

-

Auotomatic

Quick Details

-

Max.Forming Height(mm):

-

150 mm

-

Forming Width (mm):

-

610 mm

-

Forming Length (mm):

-

610 mm

-

Heating Power (kW):

-

17 kW

-

Production Speed(times/h):

-

300

-

Power Supply:

-

380 V,3 phase,50/60HZ

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Looker

-

Voltage:

-

AC380V

-

Dimension(L*W*H):

-

2620*2020*2050mm

-

Weight (T):

-

0.7 T

-

Production efficiency:

-

50~300 cycles per hour

-

Twice vacuum suction:

-

Yes

-

Heater:

-

Infrared Ceramic

-

Max forming Height:

-

150mm

-

Power(W):

-

17KW

-

Suitable material:

-

PVC,PP,PS,PC,PET,ABS etc.

-

Application:

-

food box,medical packing,toys,stationery packing

-

Material Thickness:

-

0.2~1.5mm

-

Automatic Grade:

-

Auotomatic

Product Description

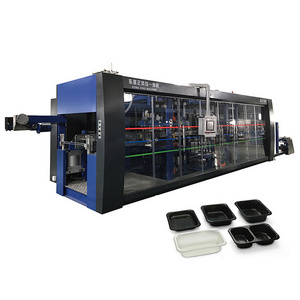

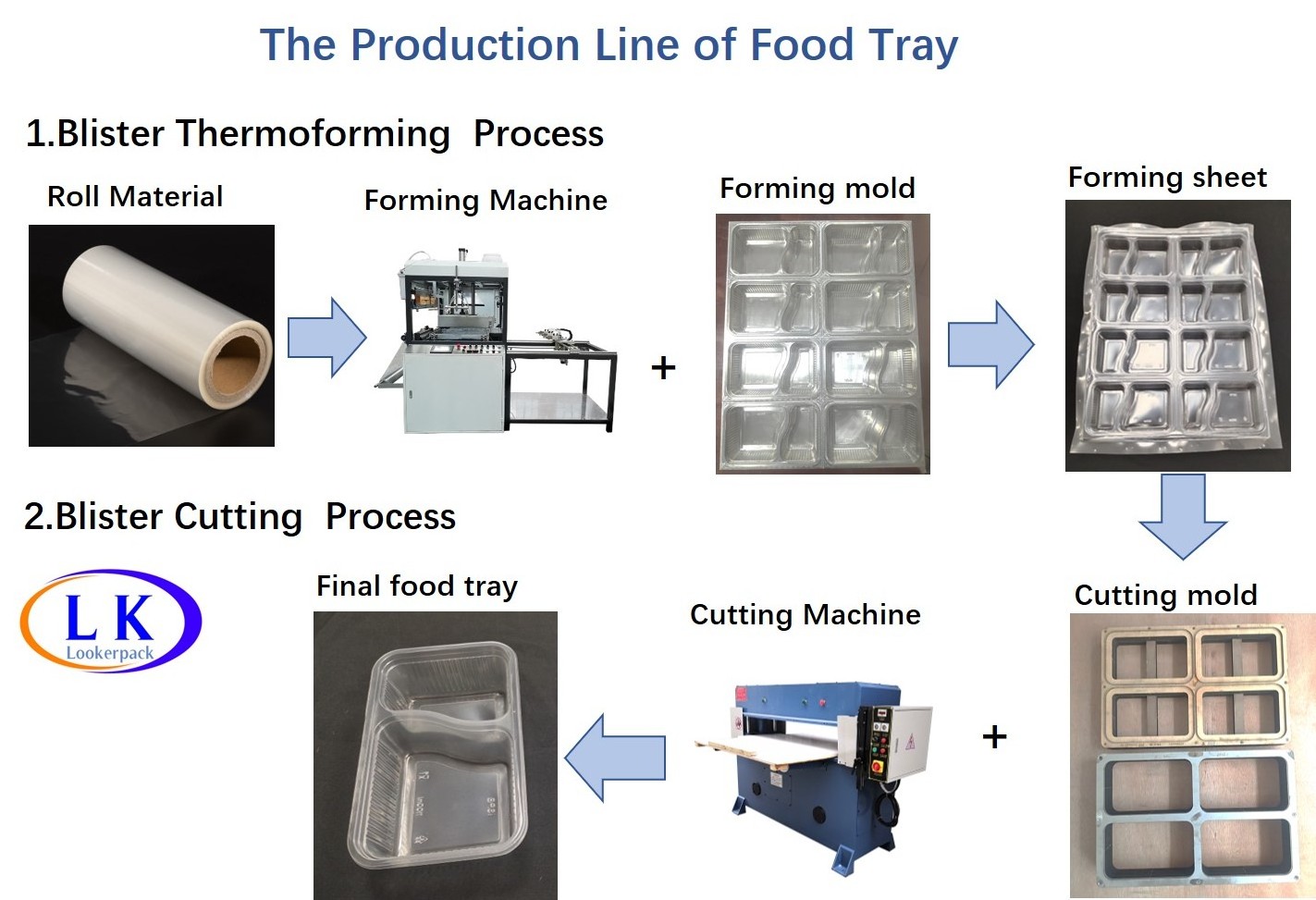

Automatic Plastic Tray Vacuum Thermoforming Machine

Application

•

T

his machine can be used for forming all kinds of plastic materials, such as PVC, ABS, PP, PC, PS, PE, PET, PETG, APET, HIPS, PMMA, Acrylic, etc.Widely used in plastic packaging, food, medicine and other industries, such as blister packaging, batteries, toys, gifts, hardware, home appliances, disposable fast food box, fruit tray, cookie box, egg tray, Medical needles packaging, oral liquid packaging tray.Special blister factory small batch blister production use.

•

Automatic blister forming machine is especially suitable for batch production.

|

Mechanical Parameters

|

|

|

|

Model

|

LK-61C

|

|

|

Power supply

|

AC380V, 220V 3 Phase (customized)

|

|

|

Max.Power

|

17KW

|

|

|

Vacuum forming capacity

|

20m³/H

|

|

|

Forming width

|

390~610 mm adjustable

|

|

|

Maximum Forming Length

|

610 mm

|

|

|

Max.forming height

|

150 mm

|

|

|

Speed

|

50-300 molds/H

|

|

|

Thickness of material

|

0.2-1.5mm

|

|

|

Machine size

|

2620*2020*2050mm

|

|

|

Net weight

|

750KG

|

|

Details

1.

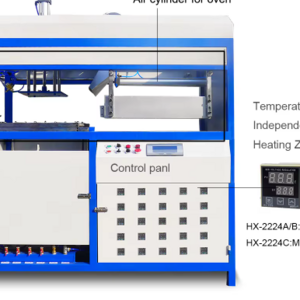

The equipment is equipped with automatic heating oven pushing--vacuum forming ----taking out the formed blister---cutting material design to minimize the manual input and improve the production efficiency and product quality.

2.

Equipped with secondary vacuum forming function, the blister can be easily formed completely.

3.

The function design of secondary vibration demoulding makes it easier to demoulding complex structure and improve the quality of molded products.

4.

This machine uses high-quality vacuum pump and is equipped with 0.1m³vacuum gas storage tank, which has stable vacuum performance and strong suction;Simple operation and maintenance.

5.

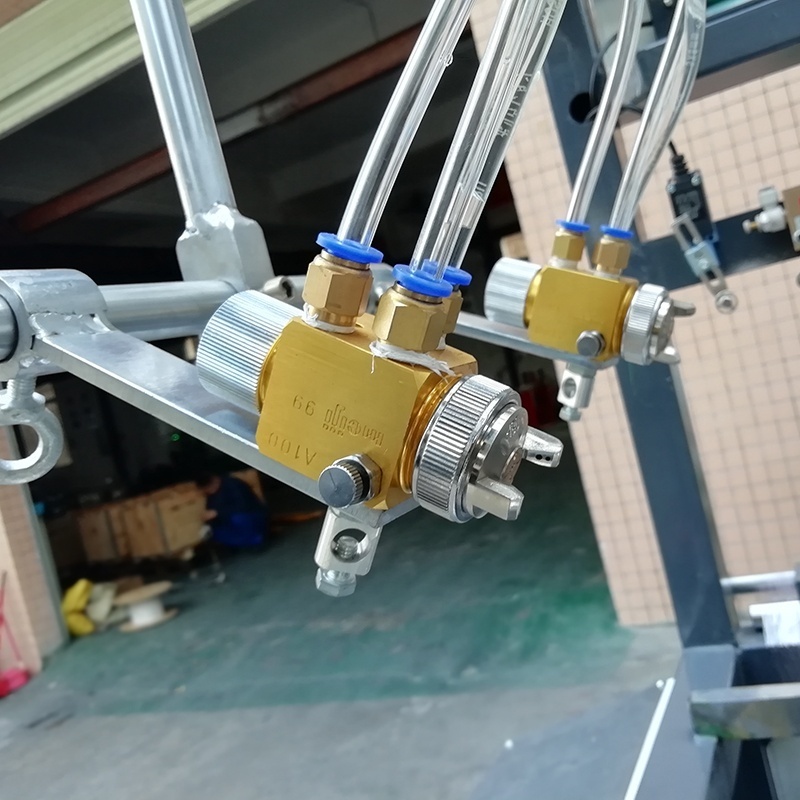

Equipped with 25 pieces of 650W ceramic infrared heater, with 25 sets of digital display temperature gauge, the temperature of each heater can be controlled flexibly and intuitively, suitable for materials of different sizes.

6.

Large air cooling design, which can make the product cool quickly.

7.

Double water spray auxiliary cooling design, greatly improve the cooling speed, especially the cooling of thick materials.

8.

PLC program control,action is fast and accurate.Automatic operation and manual operation are optional, suitable for operators of various proficiency levels.

9. Equipped with adjustable mold bed,the forming area is adjustable from 390 to 610 mm,that highly reduces the material waste.

Customer Feedback

The customer who bought our machine and would like to sell our our machine in their local market.

we got positive feedback from each of our customer because we have good term for after- sales support and good service for all customer . We are looking for machine agent all the time .let us get win- win together !

Many customers from all over the world visit our factory every year.We test machines for them at our factory ,tell them what products our machine can make and the machine working principle .

Package & Delivery

Contact Us

Hot Searches