PRECISE AND STABLE

- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

4000 KG

-

Power (kW):

-

68kw

-

Usage:

-

Woodworking Equipment

-

Application:

-

Woodworking Process

-

Name:

-

kamac

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KAMAC

-

Machine Type:

-

Mebrance press machine

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

4000 KG

-

Power (kW):

-

68kw

-

Usage:

-

Woodworking Equipment

-

Application:

-

Woodworking Process

-

Name:

-

kamac

Product Overview

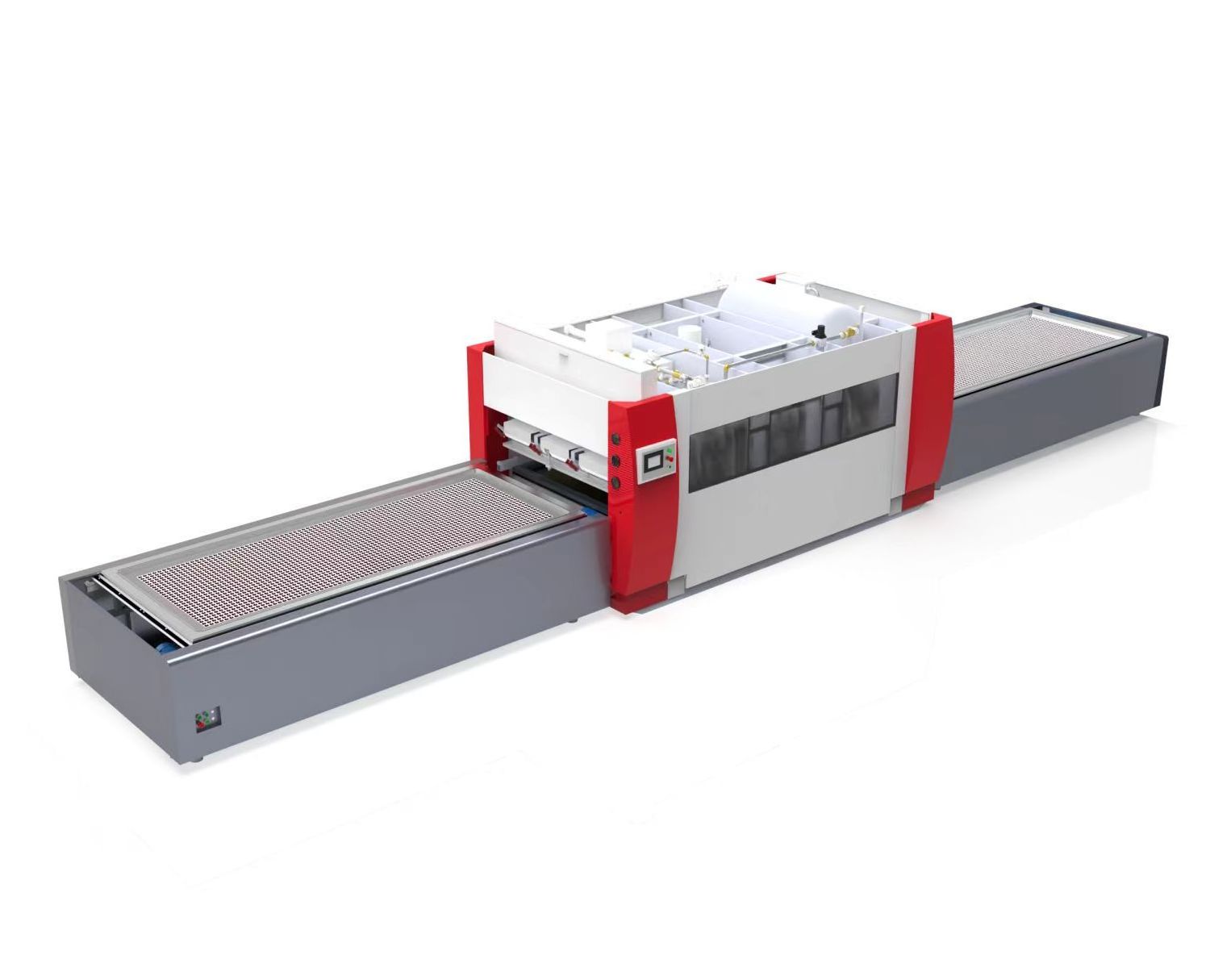

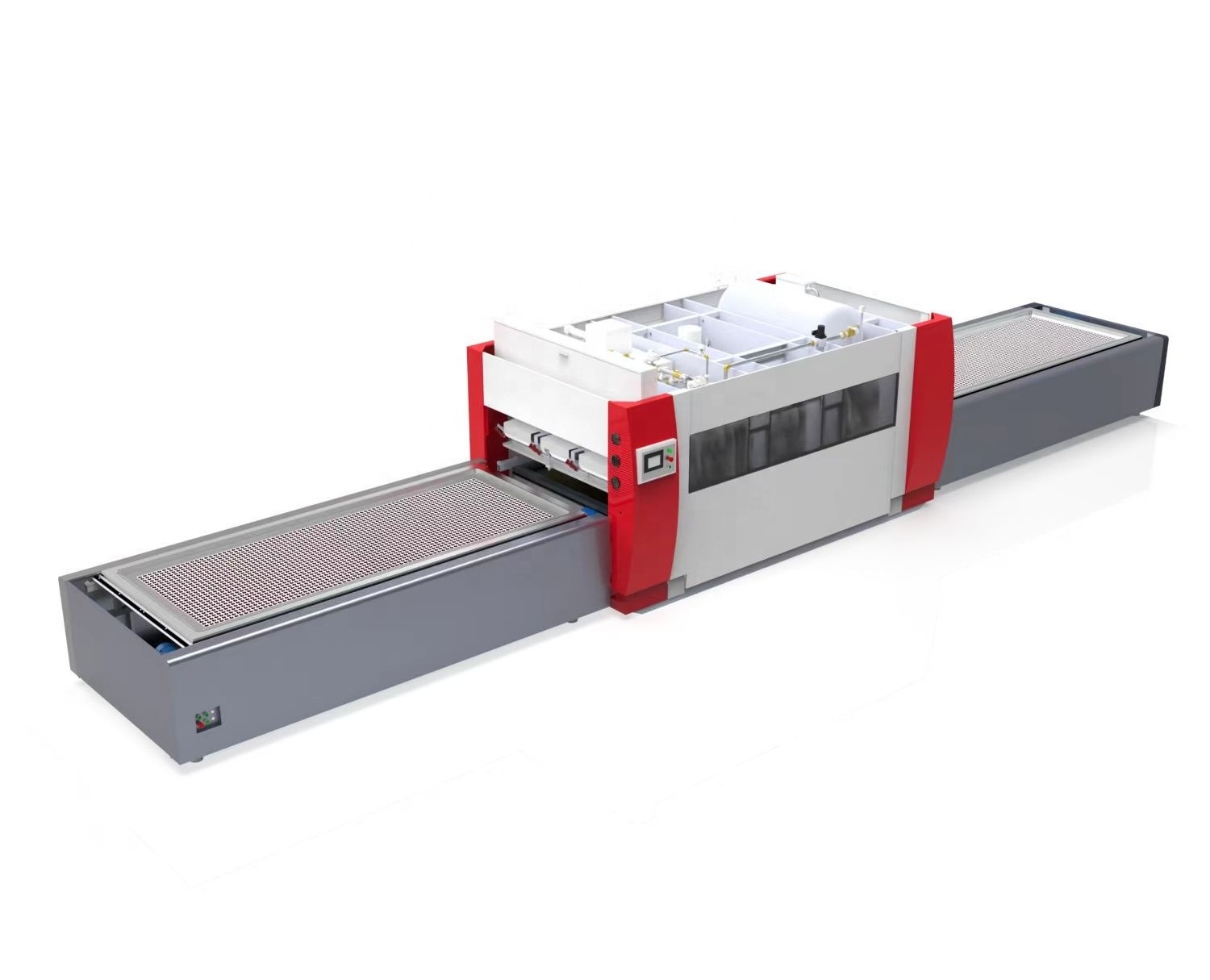

TM2767EC Mebrance press machine

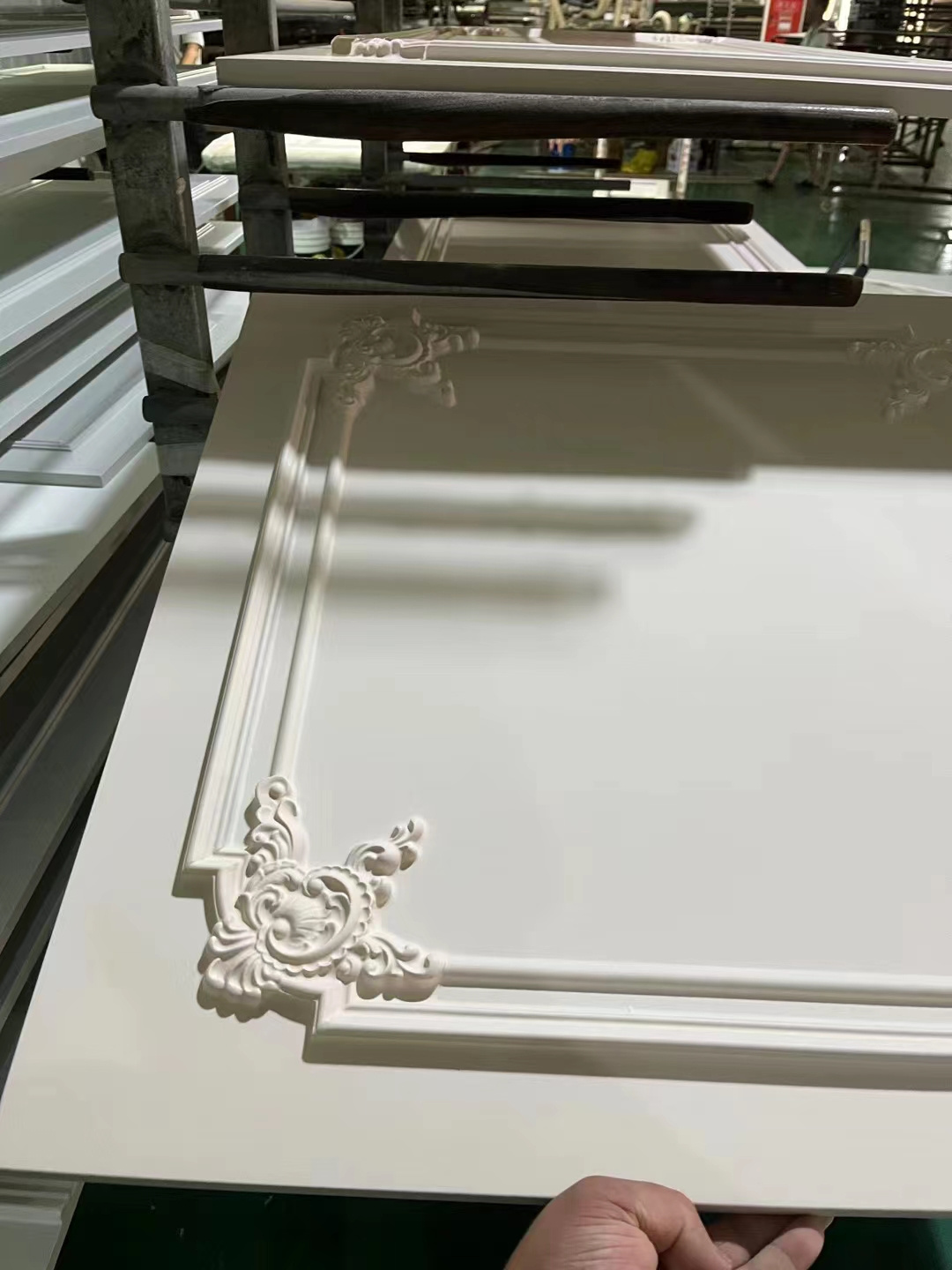

Can carry out a variety of high-grade Pvc,heat transfer printing and single-side veneer surface decoration.The various Pvc

workpieces processed by this machine are firmly bonded and do not rebound and warped.The grooves are clear and in place.

workpieces processed by this machine are firmly bonded and do not rebound and warped.The grooves are clear and in place.

FEATURES AT A GLANCE

PATENTED PRODUCTQUICK-CHANGE SYSTEM

PRECISE AND STABLE

PRECISE AND STABLE

1, the equipment frame uses 6 column structure. This structure is the first fuselage frame since our company began to produce this type of model in 2003, and the current TM2580 model and TM2580A large table model have always used this frame as the fuselage.

2, the work table in and out of the walking system is controlled by frequency converter , the use of low speed start, step by step acceleration, high speed walking, low speed stop mode.

2, the work table in and out of the walking system is controlled by frequency converter , the use of low speed start, step by step acceleration, high speed walking, low speed stop mode.

3, the operating system adopts Taiwan Delta PLC programmable controller, touch screen human-machine interface, easy control,modernization, high degree of automation.

4, the use of German technology, domestic production and assembly of directly connected 100L vacuum pump (non-German original imports, pumping capacity of 100 cubic meters per hour).

5, the electric system contactor uses France Schneider 0910, 2510. The intermediate relay uses Weidmuller intermediate relay, Taiwan Delta PLC host, Taiwan Delta touch screen. Other electrical parts use domestic components, mainly Chint.

6, the hydraulic system host adopts Taiwan system, the motor and oil pump use Taiwan Kangpepsi, the hydraulic system principle is plate insert, low failure rate, large flow, rapid pressure (pressure time is about 5 seconds, the traditional superimposed valve pressure time is about 15-20 seconds). Effectively improve production efficiency.

7, the equipment contains 1 set of partition, which can achieve the purpose of making the same PVC film of 2 different colors at the same time.

5, the electric system contactor uses France Schneider 0910, 2510. The intermediate relay uses Weidmuller intermediate relay, Taiwan Delta PLC host, Taiwan Delta touch screen. Other electrical parts use domestic components, mainly Chint.

6, the hydraulic system host adopts Taiwan system, the motor and oil pump use Taiwan Kangpepsi, the hydraulic system principle is plate insert, low failure rate, large flow, rapid pressure (pressure time is about 5 seconds, the traditional superimposed valve pressure time is about 15-20 seconds). Effectively improve production efficiency.

7, the equipment contains 1 set of partition, which can achieve the purpose of making the same PVC film of 2 different colors at the same time.

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

|

|

|

1

|

SIZE

|

10030mm× 2230mm ×2150mm

|

|

|

|

2

|

Film width:

|

2580mm×1320mm (inner diameter)

|

|

|

|

3

|

Actual power consumption

|

about 12-14kW

|

|

|

|

4

|

Rated working pressure

|

positive pressure ≤0.5Mpa Negative pressure ≥-0.095Mpa

|

|

|

|

5

|

Processing height

|

0 ~ 50mm

|

|

|

|

6

|

Total power

|

12kw

|

|

|

|

7

|

Weight: About

|

10.7T

|

|

|

PRODUCT CONFIGURATION

I

Products Description

The equipment frame uses 6 column structure. This structure is the first fuselage frame since our company began to produce this type of model in 2003, and the current TM2580 model and TM2580A large table model have always used this frame as the fuselage. The work table in and out of the walking system is controlled by frequency converter , the use of low speed start, step by step acceleration, high speed walking, low speed stop mode.3, the operating system adopts Taiwan Delta PLC programmable controller, touch screen human-machine interface, easy control,modernization, high degree of automation.

Product packaging

Our servies

We can arrage engineers to serve you

Our machines have a one-year warranty. We have a strong team specializing in after-sales service.

FAQ

1. Q: How about after-sales service?

A: Our machines have a one-year warranty. We have a strong team specializing in after-sales service. We can arrange engineers to serve you.

2. Q: Where is your factory? How can I get there?

A: Our factory is located in Jinan, Shandong Province, China, near Jinan International Airport. You can fly directly to Jinan

International Airport, or take the high-speed train or train to Jinan Station.

3.Q: How does your factory do in terms of quality control?

A: Quality is our constant theme and the cornerstone of our company's development. From the very beginning of the company, we have paid special attention to quality work. Our hot melt adhesive coating equipment is CE and SGS certified.

4.Q: What information should I tell you if I want to get a quote?

A: Details of your product, such as profiles, bonding materials, coating widths, etc

If possible, please send us pictures or design drawings and our designers will analyze your samples and provide you with exact details.Are there any other details you're not sure about? For videos, specifications, components, workflows, payment terms, etc.,please feel free to contact us.

A: Our machines have a one-year warranty. We have a strong team specializing in after-sales service. We can arrange engineers to serve you.

2. Q: Where is your factory? How can I get there?

A: Our factory is located in Jinan, Shandong Province, China, near Jinan International Airport. You can fly directly to Jinan

International Airport, or take the high-speed train or train to Jinan Station.

3.Q: How does your factory do in terms of quality control?

A: Quality is our constant theme and the cornerstone of our company's development. From the very beginning of the company, we have paid special attention to quality work. Our hot melt adhesive coating equipment is CE and SGS certified.

4.Q: What information should I tell you if I want to get a quote?

A: Details of your product, such as profiles, bonding materials, coating widths, etc

If possible, please send us pictures or design drawings and our designers will analyze your samples and provide you with exact details.Are there any other details you're not sure about? For videos, specifications, components, workflows, payment terms, etc.,please feel free to contact us.

Hot Searches