- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customer local standard

-

Dimension(L*W*H):

-

depends

-

Weight:

-

1500 KG

-

Marketing Type:

-

New Product 2023

-

Product name::

-

Flotation Machine Separator

-

Brand Name::

-

Eastman

-

Type::

-

Flotation Machine

-

Place of Origin::

-

China

-

Voltage::

-

Customer local standard

-

Application::

-

gold, tin, tan-ni, chrome

-

Capacity::

-

10-50TPH

-

Motor::

-

Electric

-

Keywords::

-

flotation cell

-

Warranty of core components::

-

1 year

Quick Details

-

Production Capacity:

-

1-500tpd

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Eastman

-

Voltage:

-

Customer local standard

-

Dimension(L*W*H):

-

depends

-

Weight:

-

1500 KG

-

Marketing Type:

-

New Product 2023

-

Product name::

-

Flotation Machine Separator

-

Brand Name::

-

Eastman

-

Type::

-

Flotation Machine

-

Place of Origin::

-

China

-

Voltage::

-

Customer local standard

-

Application::

-

gold, tin, tan-ni, chrome

-

Capacity::

-

10-50TPH

-

Motor::

-

Electric

-

Keywords::

-

flotation cell

-

Warranty of core components::

-

1 year

Product Introduction

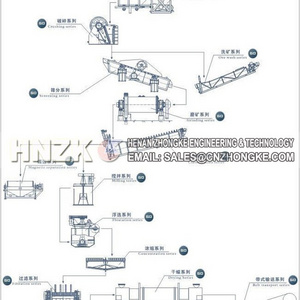

Lead-Zinc Ore Beneficiation Process

Crushing And Screening

Most of the lead-zinc deposits are carbonate deposits, and some are skarn-type, spout-sedimentary deposits.

The main metal minerals in the deposit are galena, sphalerite, pyrite and chalcopyrite. Generally, a three-stage one-closed circuit crushing process is adopted. The crushing and screening equipment commonly used in the beneficiation process of lead-zinc mine is as follows:

The main metal minerals in the deposit are galena, sphalerite, pyrite and chalcopyrite. Generally, a three-stage one-closed circuit crushing process is adopted. The crushing and screening equipment commonly used in the beneficiation process of lead-zinc mine is as follows:

Grinding

According to the different properties, genesis, structure and structure of the lead-zinc ore in different dressing plants, there are large differences in the design of the grinding process. Because of economic considerations, small dressing plants often adopt a simple grinding process to facilitate operation and management. In order to obtain better economic and technical effects, large-scale beneficiation plants usually conduct multiple scheme comparisons to determine the grinding process.

Flotation

Flotation

1. Mixed flotation-lead zinc separation Process advantages: The flotation process performs two mixed flotation of lead and zinc under weak alkaline conditions, and separates lead and zinc under weak acid conditions. The process of mixing lead and zinc twice can discard the tailings at one time and reduce metal loss. In the lead-zinc ore beneficiation process, the destination of the coarse concentrate and the location of the separation ore return can be flexibly configured to adapt to changes in the grade of the original ore.

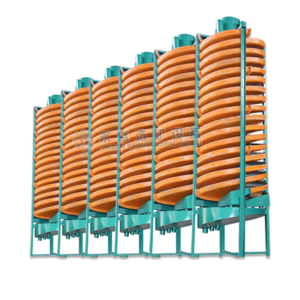

2. Floatable for lead and zinc, separation of lead and zinc, mixed floatation of zinc and sulfur, separation of zinc and sulfur Process advantages: Floatable lead and zinc eliminate the forced suppression of easily floatable minerals by priority flotation, and also avoid the forced activation of difficult floated zinc minerals by mixed flotation, thereby reducing the consumption of reagents and the subsequent separation of residual reagents Impact. In the lead-zinc ore beneficiation process, the commonly used equipment is a mechanically agitated flotation machine. This year, with the improvement of flotation machine technology, the modified and upgraded version of mechanical agitated flotation machine has been widely used in the newly-built concentrator.

2. Floatable for lead and zinc, separation of lead and zinc, mixed floatation of zinc and sulfur, separation of zinc and sulfur Process advantages: Floatable lead and zinc eliminate the forced suppression of easily floatable minerals by priority flotation, and also avoid the forced activation of difficult floated zinc minerals by mixed flotation, thereby reducing the consumption of reagents and the subsequent separation of residual reagents Impact. In the lead-zinc ore beneficiation process, the commonly used equipment is a mechanically agitated flotation machine. This year, with the improvement of flotation machine technology, the modified and upgraded version of mechanical agitated flotation machine has been widely used in the newly-built concentrator.

Processing Flow Overview

Processing Flow Overview▼

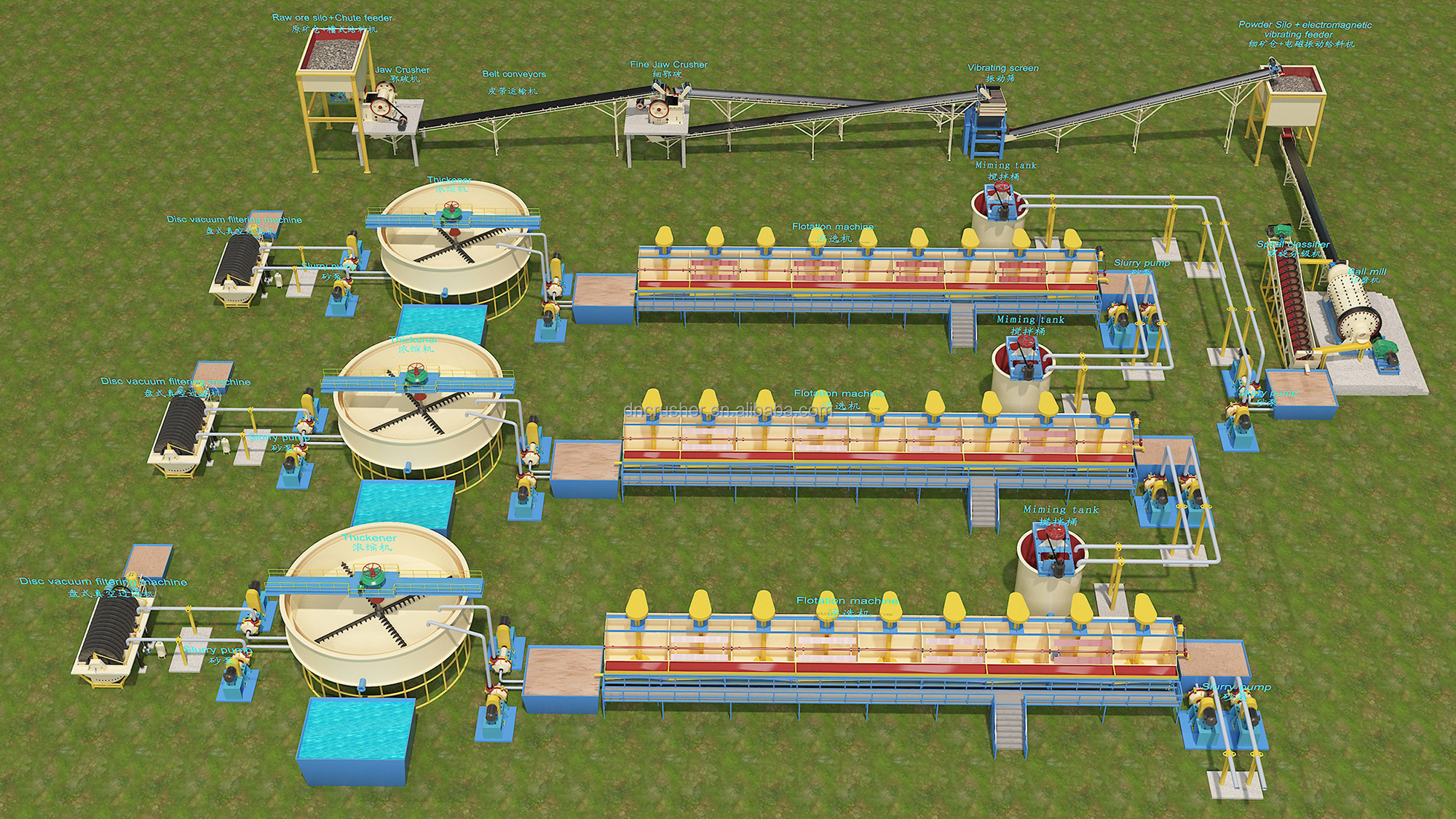

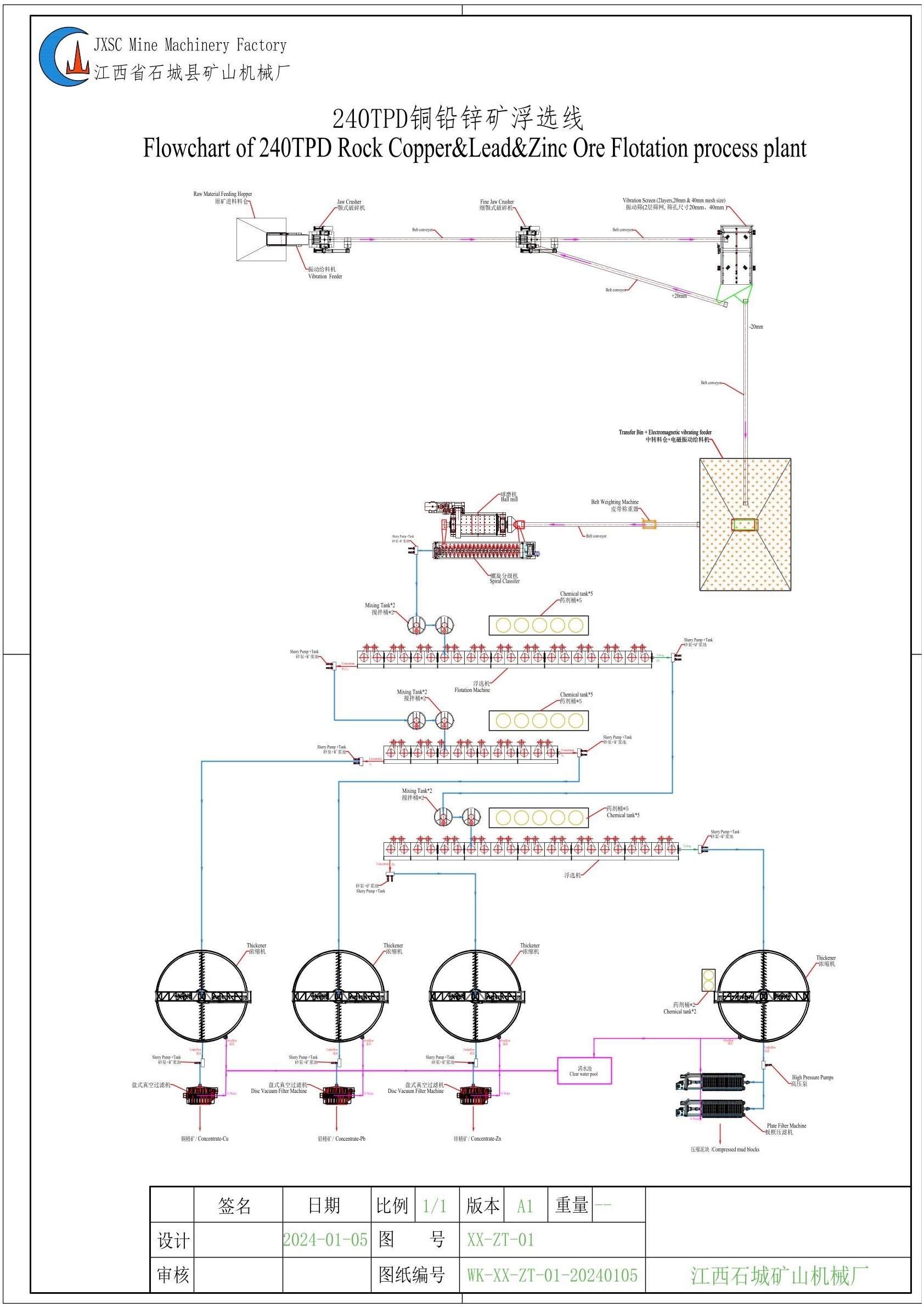

2. Output of primary jaw crusher through belt conveyor go to fine jaw crusher for further crushing to 20-60mm small size. Here secondary jaw crusher is fine crushing 40-100mm rock to 20-60mm.

3. Output of fine jaw crusher through belt conveyor goes to vibrating screen for sieving above 20mm and below 20mm. Here the vibrating screen is with 1 deck sieve 20mm hole size.

4. Above 20mm from over screen are back to fine jaw crusher for reprocessing via belt conveyor.

5. Below 20mm from under-screen through belt conveyor go to fine ore silo, through the electromagnetic vibrating feeder to feed ball mill. Here ball mill can grind 0-20mm ore to powder size 0-1mm.

6. Output of ball mill flow to spiral classifier form a closed grinding system so that above 90% output is 200mesh which meet with flotation condition.

7. Underflow of spiral classifier goes to one slurry tank, then use a slurry pump to send it to 1st mixing tank, then to 1st flotation machine for separating out the lead.

8. The concentrate of 1st flotation machine goes to one slurry tank, use a slurry pump to send it to 1st thickener, underflow of thickener through the slurry pump goes to 1st disc vacuum filtering machine for dehydration, the final product is lead concentrate.

9. The tailing of the 1st flotation machine goes to one slurry tank, use a slurry pump to send it to 2nd mixing tank, then to 2nd flotation machine for separating out zinc.

10. The concentrate of the 2nd flotation machine goes to one tank, use a slurry pump to send it to the 2nd thickener, underflow of thickener through slurry pump go to 2nd disc vacuum filtering machine for dehydration, the final product is zinc concentrate.

11. The tailing of the 2nd flotation machine goes to one tank, and using a slurry pump sends it to 3rd flotation machine for separating out barite.

12. The concentrate of the 3rd flotation machine to one tank, use a slurry pump to send it to the 3rd thickener, underflow of thickener through slurry pump go to 3rd disc vacuum filtering machine for dehydration, the final product is barite concentrate.

Main Product

Packaging&Dilvery

●Ways Of Packing

● Shiping by sea/air freight

|

1.Small parts packed in the wooden cases.

|

or any way the customer requires.

|

|

2.Big parts packed by plastic membrane.

|

|

|

3.The whole big machine is loaded in the container.

|

|

Our Company

1.Inquiry and consulting support.

2.Ore sample testing support.

3.View our Factory.

4.Design Flowchart.

1.Training how to instal the machine, training how to use the machine.

2. 1 year warranty .

3.Engineers available to service machinery overseas.

FAQ

1.How is the quality of your products?(mining equipment/machine)

Answer: Our products are manufactured strictly according to national and international standard, and we will do a test on every machine before delivery.

2.Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description or promise we made before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before factory delivery, which is international trade practice; Finished product pictures will be provided to customers before delivery.

Contacts

If you are interested in our products, please don't hesitate to contact us. Could you tell me the following questions, so that I can give you a complete solution, including best Exw-works Price Quotation!

1. Which machine do you need? like gold washing machine, spiral chute, vibrating screen, Jig separator, Shaking table, etc.

2. What is your raw ore that you plan to process? like gold ore, diamond ore, tantalite or silica sand, etc.

3. What is the capacity you need? Like 10 tones per hour.

4. What is the feeding size to the machine? and what is the discharging-material size that you require?

Sincerely welcome to send your inquiry,you can get best quotation and professional service.

Hot Searches