- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.34%

-

CrO Content (%):

-

0.1-0.3%

-

SiC Content (%):

-

1.2-1.4

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Fire Clay Brick

-

Brand Name:

-

Rongsheng

-

Product name:

-

fire clay brick

-

Weight of brick:

-

3-4KG/Pices

-

Bulk density g/cm3:

-

2.00-2.35

-

Apparent porosity/%:

-

≤22

-

Cold Crushing Strength Mpa:

-

≥25

-

Permanent linear change≥:

-

1100

-

Refractoriness°C:

-

≥1700

-

Application:

-

Metallurgy

-

Certificate:

-

ISO9001

-

Sample:

-

Provide

Quick Details

-

SiO2 Content (%):

-

50%~65%

-

Al2O3 Content (%):

-

38-48%

-

MgO Content (%):

-

0.8-1.2

-

CaO Content (%):

-

0.34%

-

CrO Content (%):

-

0.1-0.3%

-

SiC Content (%):

-

1.2-1.4

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Fire Clay Brick

-

Brand Name:

-

Rongsheng

-

Product name:

-

fire clay brick

-

Weight of brick:

-

3-4KG/Pices

-

Bulk density g/cm3:

-

2.00-2.35

-

Apparent porosity/%:

-

≤22

-

Cold Crushing Strength Mpa:

-

≥25

-

Permanent linear change≥:

-

1100

-

Refractoriness°C:

-

≥1700

-

Application:

-

Metallurgy

-

Certificate:

-

ISO9001

-

Sample:

-

Provide

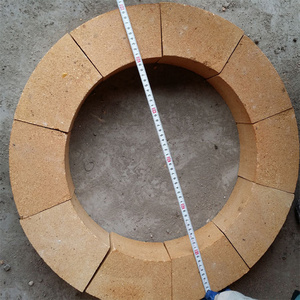

Standard sizing: 230 x 114 x 65 mm ,Special size and OEM Service also provide!

The size is precise, providing kinds of shapes according to customer's drawing

The size is precise, providing kinds of shapes according to customer's drawing

Rongsheng refractory 15 years professional refractory manufacturer

!!!

Customize products according to your needs

OEM/ODM

Products Conform International Standards and Are Strictly Executed According To The Contract

Provide Refractory Construction and Technical Guidance

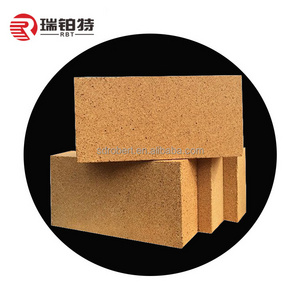

Fire clay brick is made of local top grade fireclay materials under the high temperature according to the lasted national standard, which possesses even bulk density, high strength, low thermal conductivity and low impurity. Fire clay refractory brick has wide usage and the largest production.

1. Low coefficient of linear expansion

2. Low thermal conductivity,

3. Strong resistance to the acid slag erosion,

4. Excellent thermal shock resistance,

5. High Refractoriness under load,

6. Low high-temperature creep rate.

If you want to know more products, please contact us immediately, we have professional engineers to answer your questions

If you have more needs, we can customize the size, material, etc.

|

Mullite Bricks

|

|

|

|

|

|

|||||

|

Item

|

|

MU 60

|

MU 65

|

MU 70

|

MU 75

|

|||||

|

Chemical Composition |

Al2O3

|

≥60

|

≥65

|

≥70

|

≥75

|

|||||

|

|

SiO2

|

≤35

|

≤33

|

≤26

|

≤24

|

|||||

|

|

Fe2O3

|

≤1.0

|

≤1.0

|

≤0.6

|

≤0.4

|

|||||

|

Bulk Density g/cm3

|

|

≥2.55

|

≥2.55

|

≥2.55

|

≥2.55

|

|||||

|

Permanent Linear Change On Reheating (%) 1500ºCX2h

|

|

0~+0.4

|

0~+0.4

|

0~+0.4

|

0~+0.4

|

|||||

|

Apparent Porosity %

|

|

≤17

|

≤17

|

≤17

|

≤18

|

|||||

|

Thermal Conductivity (W/MK) 1000ºC

|

|

1.74

|

1.84

|

1.95

|

1.95

|

|||||

|

Cold Crushing Strength Mpa

|

|

≥60

|

≥60

|

≥80

|

≥80

|

|||||

|

Thermal Expansion coefficient 10-6/ºC

|

|

0.6

|

0.6

|

0.6

|

0.55

|

|||||

|

0.2Mpa Refractoriness Under Load T0.6 ºC

|

|

≥1580

|

≥1600

|

≥1600

|

≥1650

|

|||||

|

Thermal Shock Resistances 1000ºC water cycles

|

|

≥18

|

≥18

|

≥18

|

≥18

|

|||||

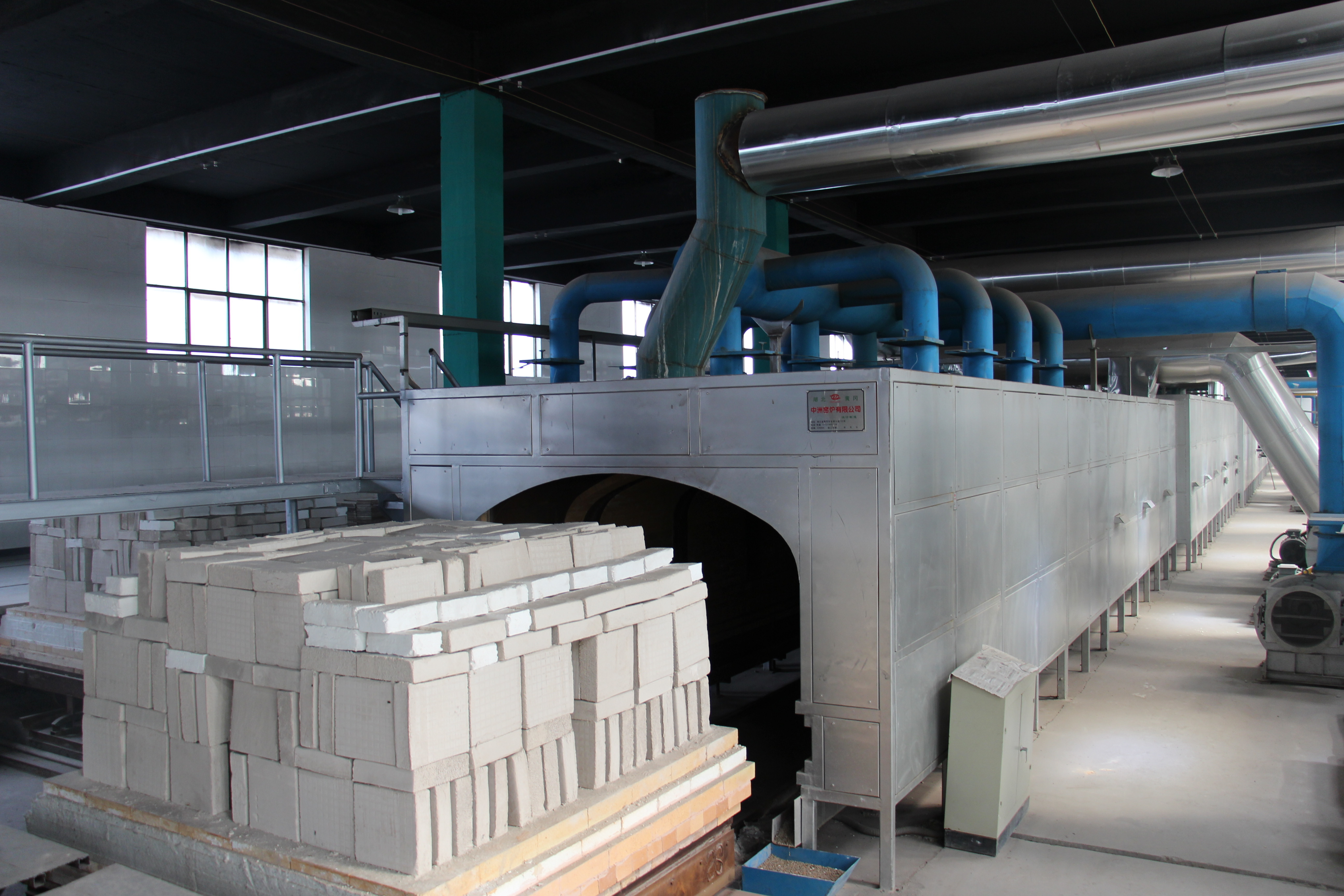

I

ron & steel making industry

Blast furnace, hot blast furnace(stove), pellet shaft furnace, hot metal ladle, steel ladle, tundish, eating furnace, soaking pit furnace, heat treatment furnace, refining furnace, reheating furnace, metal mixter furnace, cupola furnace etc thermal technology equipment

Non-ferrous Metal industry

Smelting furnace, reverberatory furnace etc

Building materials industry

Cement kiln, glass kiln, ceramic kiln, lime kilns, kiln car, tunnel kiln, rotary kiln

Energy&Incineration

Coke oven, general boiler, power generation boiler, circulating fluidized bed boiler, electric furnace, carbon roasting furnace, waste incinerators

Others

Petrochemical industry furnace, Pizza oven

Q1. Are you Manufacturer?

A: Yes, of course, our factory is in Xinmi,zhengzhou city,Henan province.

Q2. Can we visit your company?

A: Sure,welcome at any time,seeing is believing.

Q3. Do you accept OEM?

A: Yes, we can do OEM.

Q4. What's the MOQ of trial order?

A: No limit,We can offer the best suggestions and solutions according to your condition.

Q5. What are the payment terms?

A: Usually T/T,but L/C,Western Union etc are available for us.

Q6. How long is delivery time?

A: The delivery time will be determined according to the quantity of the order.

Q7.How about your company's certification?

A: ISO9001 and Test Report,also we could apply other necessary certification.

Hot Searches