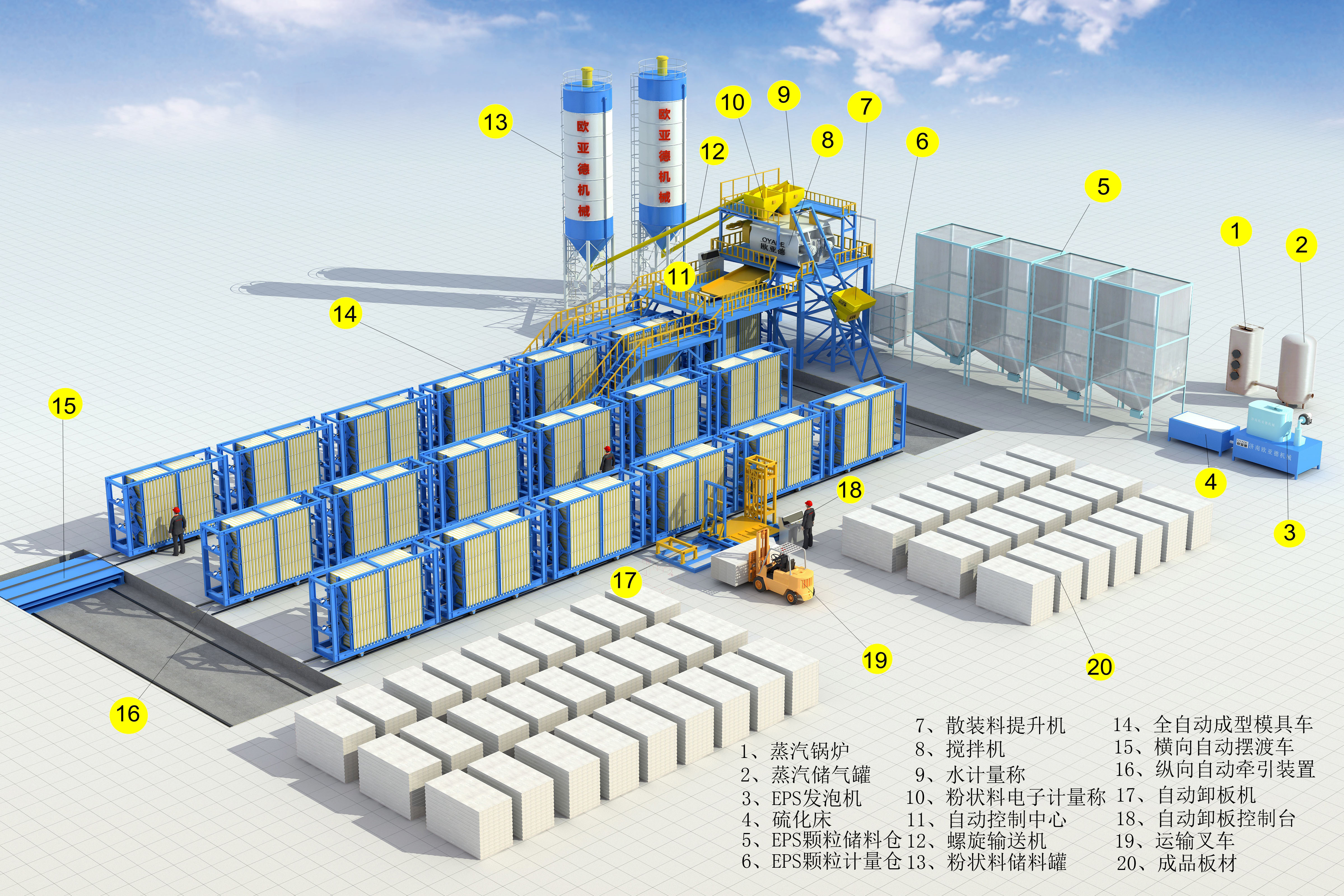

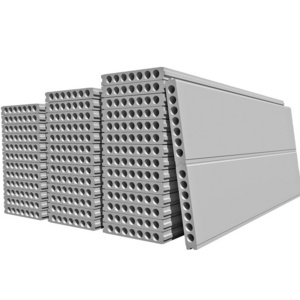

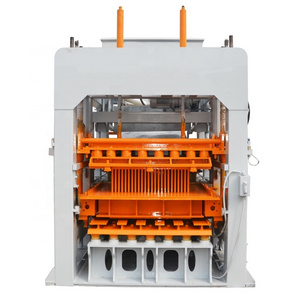

OYD group was establised in 2008. we have 5 subsidiaries for producing different kinds of products, eps concrete wall panel machine; mgo board production line; hollow glass aluminum spacer; Laser cutting, etc. We moved to a new area, which has 66000 sqm. Plant area occupy 60000sqm and the office building occupy 6000sqm.

Our advantages

1. Rich experience in mechanical design and manufacturing, professional import and export services, we commitment to provide the best integrated solutions for customers. We have lots successful project in both the domestic and overseas market and enjoyed a good reputation in this field.

2.We have a number of experienced technical engineers who are specialized in the training, guiding and consulting, could help customer solve any problems for clients.

3. All-around technical service: we provide technical formula for clients, to help clients to occupy the leading position in the market.

4. We have independent design and development team, a standardization laboratory, and has established deep-level cooperationwith well-known research institutes such as Shandong University, Shandong Architecture University and Jinan University. We already got 36 patents.

5. Work together with customer to develop new product