- Product Details

- {{item.text}}

Quick Details

-

Range of Spindle Speed(r.p.m):

-

16 - 1400 r.p.m

-

Width of bed (mm):

-

400

-

Max. Turned Length (mm):

-

1850 mm

-

Spindle Motor Power(kW):

-

7.5

-

Year:

-

New

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Luxing

-

Model Number:

-

CA6240

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

3200*1140*1750mm

-

Weight (KG):

-

2220 KG

-

Automatic Grade:

-

Manual

-

Name:

-

Universal Lathe Machine

-

Keyword:

-

METAL PROCESSING HORIZONTAL LATHE MACHINE

-

Spindle bore:

-

52/80/105mm

-

Distance between centers:

-

1000mm/1500mm/2000mm/3000mm

-

Chuck:

-

3-jaw Chuck

-

Max.swing over bed:

-

400mm

-

Swing over cross slide:

-

210mm

-

Spindle taper:

-

MT6

-

Tailstock taper:

-

M.T.No.5

Quick Details

-

Max. Length of Workpiece (mm):

-

1500

-

Machining Capacity:

-

Medium Duty

-

Spindle Bore(mm):

-

80 m'm

-

Range of Spindle Speed(r.p.m):

-

16 - 1400 r.p.m

-

Width of bed (mm):

-

400

-

Max. Turned Length (mm):

-

1850 mm

-

Spindle Motor Power(kW):

-

7.5

-

Year:

-

New

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Luxing

-

Model Number:

-

CA6240

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

3200*1140*1750mm

-

Weight (KG):

-

2220 KG

-

Automatic Grade:

-

Manual

-

Name:

-

Universal Lathe Machine

-

Keyword:

-

METAL PROCESSING HORIZONTAL LATHE MACHINE

-

Spindle bore:

-

52/80/105mm

-

Distance between centers:

-

1000mm/1500mm/2000mm/3000mm

-

Chuck:

-

3-jaw Chuck

-

Max.swing over bed:

-

400mm

-

Swing over cross slide:

-

210mm

-

Spindle taper:

-

MT6

-

Tailstock taper:

-

M.T.No.5

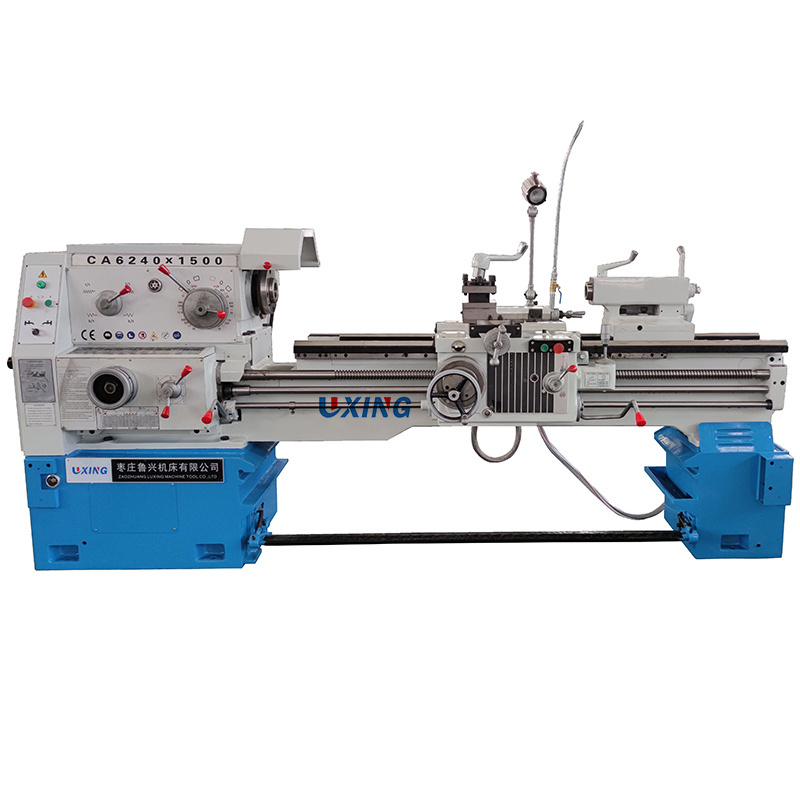

horizontal manual lathe machine tornos para metal CA6240

Main Feature:

1.Bed guideway is harden and tempered by super audio quenching and precision grinding

2.Precision grinding of the main shaft box, low noise.

3.Many thread type can be choosen

4.Electrical safety performance is good, high reliability

2.Precision grinding of the main shaft box, low noise.

3.Many thread type can be choosen

4.Electrical safety performance is good, high reliability

Application:

1.CA series of ordinary horizontal lathe is suitable for turning inside and outside cylindrical surface, conical surface and other rotating surface, turning various metric and inch, modulus and pitch thread, and can carry out the work of drilling and pulling oil groove, is a very versatile horizontal lathe, widely used in all kinds of shaft and disc parts of the batch processing.

2.This series of lathe bed width in general lathe, rail width 400mm has a high stiffness; guide rail surface is quenched by medium frequency, and is durable.

3.The machine operation is flexible and concentrated, the apron with fast moving mechanism. Using single handle vivid of the operation, pleasant and good.

4.Machine tool structure rigidity and transmission rigidity are higher than the general lathe, the power utilization ratio is

high, is suitable for the strong cutting.

5.Machine tool factory in strict accordance with the test procedures for testing, and make a strong cutting test, to ensure that the machine has a good accuracy and reliability.

2.This series of lathe bed width in general lathe, rail width 400mm has a high stiffness; guide rail surface is quenched by medium frequency, and is durable.

3.The machine operation is flexible and concentrated, the apron with fast moving mechanism. Using single handle vivid of the operation, pleasant and good.

4.Machine tool structure rigidity and transmission rigidity are higher than the general lathe, the power utilization ratio is

high, is suitable for the strong cutting.

5.Machine tool factory in strict accordance with the test procedures for testing, and make a strong cutting test, to ensure that the machine has a good accuracy and reliability.

Machine main specifications:

|

Type

|

CA6140

CA6240 |

CA6150

CA6250 |

CA6161

CA6261 |

CA6166

CA6266 |

CA6180

CA6280 |

|||||

|

Max. swing over bed

|

400mm

|

500mm

|

610mm

|

660mm

|

800mm

|

|||||

|

Max. swing over carriage

|

210mm

|

300mm

|

370mm

|

400mm

|

540mm

|

|||||

|

Max. swing in gap

|

630mm

|

720mm

|

830mm

|

880mm

|

1020mm

|

|||||

|

Max. effective length in gap

|

210mm

|

|

|

|

|

|||||

|

Max. length of workpiece

|

750/1000/1500/2000/2200/3000/4000mm

|

|

|

|

|

|||||

|

Width of bed

|

400mm

|

|

|

|

|

|||||

|

Section of turning tool

|

25*25 mm

|

|

|

|

|

|||||

|

Main spindle motor

|

7.5kw(10HP)

|

|

|

|

|

|||||

|

Spindle

|

|

|

|

|

|

|||||

|

Spindle speed

|

16--1400rpm(24step)

|

|

|

|

|

|||||

|

Spindle bore

|

52mm (B: 80mm),(C: 105mm)

|

|

|

|

|

|||||

|

Spindle taper

|

No.6(MT6)(90 1:20)[113:20]

|

|

|

|

|

|||||

|

Feed

|

|

|

|

|

|

|||||

|

NO. of feed

|

(64 kinds)(for each)

|

|

|

|

|

|||||

|

Range of metric threads

|

(1-192mm) (44 kinds)

|

|

|

|

|

|||||

|

Range of inch threads

|

(1-24tpi) (21kinds)

|

|

|

|

|

|||||

|

Range of module threads

|

0.25-48 (module 39 kinds)

|

|

|

|

|

|||||

|

Range of diametral pitch threads

|

1-96DP (37 kinds)

|

|

|

|

|

|||||

|

Tailstock

|

|

|

|

|

|

|||||

|

Max. tailstock spindle travel

|

150mm

|

|

|

|

|

|||||

|

Tailstock spindle diameter

|

75mm

|

|

|

|

|

|||||

|

Taper of tailstock spindle centre hole

|

NO.5(MT5)

|

|

|

|

|

|||||

|

Packing dimensions (L*W*H)

|

|

|

|

|

|

|||||

|

Overall dimensions for 750mm

|

2440*1140*1750mm

|

|

|

|

|

|||||

|

Overall dimensions for 1000mm

|

2700*1140*1750mm

|

|

|

|

|

|||||

|

Overall dimensions for 1500mm

|

3200*1140*1750mm

|

|

|

|

|

|||||

|

Overall dimensions for 2000mm

|

3700*1140*1750mm

|

|

|

|

|

|||||

|

Overall dimensions for 2200mm

|

4030*1140*1750mm

|

|

|

|

|

|||||

|

Overall dimensions for 3000mm

|

4800*1140*1750mm

|

|

|

|

|

|||||

|

Overall dimensions for 4000mm

|

5680*1140*1750mm

|

|

|

|

|

|||||

|

Weight (kg)

|

|

|

|

|

|

|||||

|

Overall dimensions for 750mm

|

2100

|

2170

|

2300

|

2400

|

2520

|

|||||

|

Overall dimensions for 1000mm

|

2200

|

2260

|

2380

|

2580

|

2720

|

|||||

|

Overall dimensions for 1500mm

|

2380

|

2450

|

2577

|

2830

|

3000

|

|||||

|

Overall dimensions for 2000mm

|

2750

|

2800

|

3000

|

3050

|

3300

|

|||||

|

Overall dimensions for 2200mm

|

2800

|

3000

|

3150

|

3400

|

3500

|

|||||

|

Overall dimensions for 3000mm

|

3300

|

3500

|

3600

|

4000

|

4220

|

|||||

|

Overall dimensions for 4000mm

|

3500

|

3800

|

3950

|

4600

|

4900

|

|||||

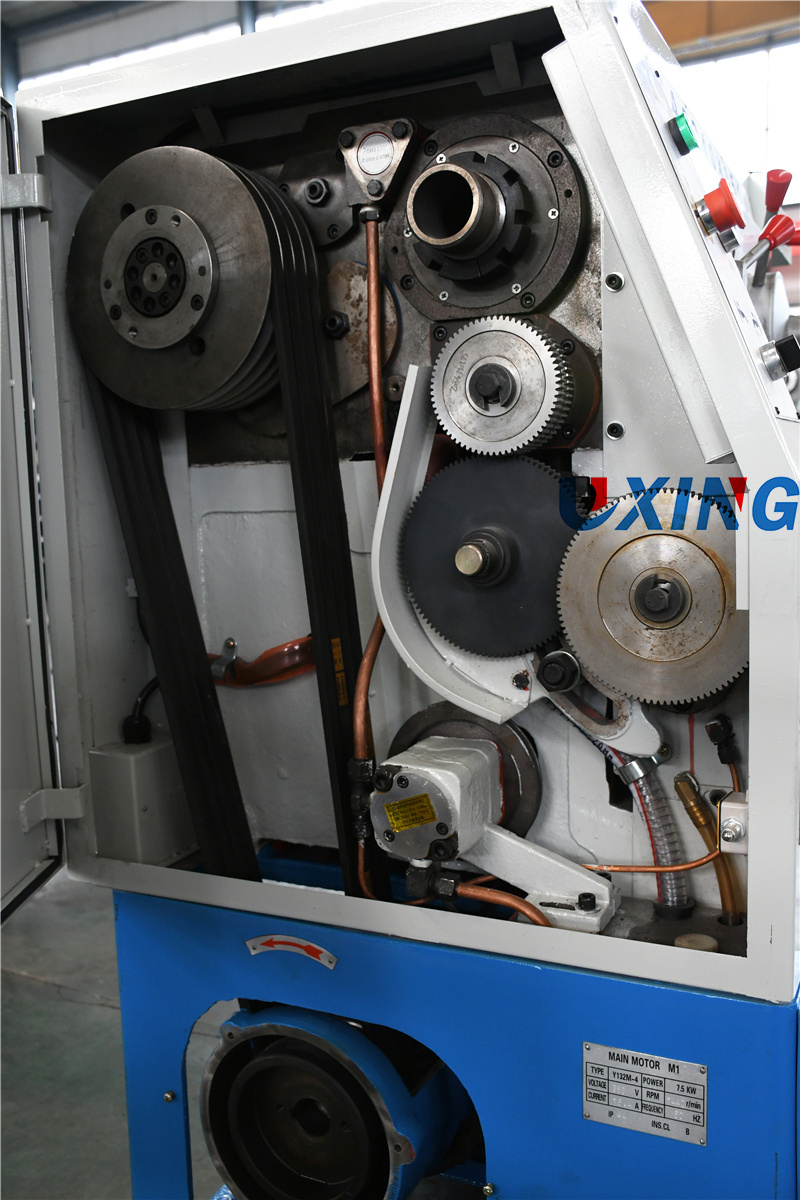

Details:

1).Spindle head box

Great quality gears make the spindle head box perform stable and precisely.

Great quality gears make the spindle head box perform stable and precisely.

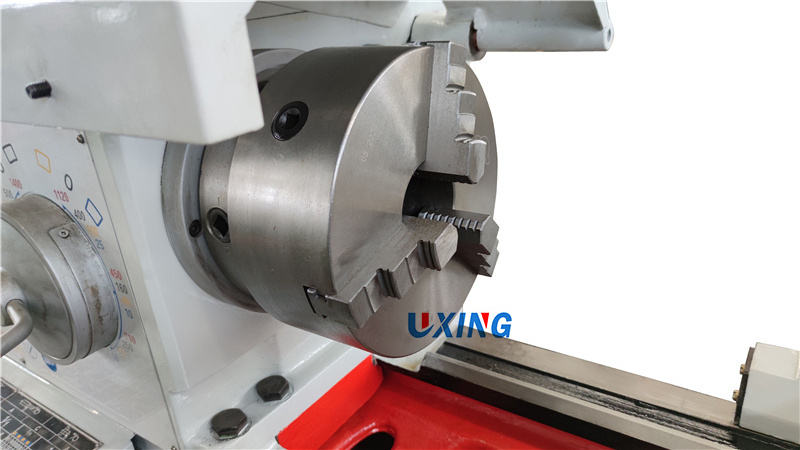

2).Spindle bore and chuck protect

Spindle bore:52,80,105mm.

Standard:3 jaw chuck

Spindle bore:52,80,105mm.

Standard:3 jaw chuck

Optional:4 jaw chuck(need add extra cost).

3).400mm width Quenching bed;

Lengh above 1500mm,steady rest and follow rest are standard.

Width is bigger than normal lathe,with high hardness,wear quenching.

Lengh above 1500mm,steady rest and follow rest are standard.

Width is bigger than normal lathe,with high hardness,wear quenching.

4).Tool post

Standard Tool Post:

Standard Tool Post:

Optional:Quick Change Tool Post(need add extra cost)

5).2 Axis DRO

2 Axis(DRO) Digital Read Out need extra cost.

Related products:

FAQ:

1:How can I choose the most suitable machines?

A: Please tell me your specifications (or send your workpiece drawing to us) ,we can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Lathe Machines ,Drilling Machine ,Radial Drilling Machine ,Band Saw Machine ,Shaper machine and so on .

3: How long is the delivery time?

For standard machines,it would be around 30 days;For non-standard machines and customized machine according to client’s specifications requirements,it wouble be a little longer.

4.Where is our factory located? How can I visit there?

A : Our factory is located in Tengzhou City ,Shandong Province,277599 China.

You are warmly welcomed to visit us.

5. What is your trade terms?

A : FOB, CFR and CIF all acceptable.

6: What's the Payment Terms?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;

Irrevocable LC at sight .

7: What's the MOQ?

A: 1 set .

A: Please tell me your specifications (or send your workpiece drawing to us) ,we can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Lathe Machines ,Drilling Machine ,Radial Drilling Machine ,Band Saw Machine ,Shaper machine and so on .

3: How long is the delivery time?

For standard machines,it would be around 30 days;For non-standard machines and customized machine according to client’s specifications requirements,it wouble be a little longer.

4.Where is our factory located? How can I visit there?

A : Our factory is located in Tengzhou City ,Shandong Province,277599 China.

You are warmly welcomed to visit us.

5. What is your trade terms?

A : FOB, CFR and CIF all acceptable.

6: What's the Payment Terms?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;

Irrevocable LC at sight .

7: What's the MOQ?

A: 1 set .

Hot Searches