- Product Details

- {{item.text}}

Quick Details

-

No. of Slitting Lines:

-

3 - 5

-

Coil Weight (T):

-

10 T

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Zhongtuo

-

Voltage:

-

380v/50hz/3ph

-

Rated Power:

-

around 100Kw

-

Dimension(L*W*H):

-

25*7m

-

Weight:

-

18T

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

roll slitting machine

-

.line speed:

-

0-60m/min

-

Cutting thickness:

-

0.5-2.0mm

-

width:

-

500-1500(Max)

-

diagonal tolerance:≤±1mm/2000mm:

-

≤±1mm/2000mm

-

.length tolerance:

-

≤±0.5mm/2000mm

-

Type:

-

Shearing Machines

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

CE ISO

Quick Details

-

Cutting Width (mm):

-

100 - 1000 mm

-

Material Thickness(mm):

-

0.2 - 3 mm

-

Cutting Speed(m/min):

-

10 - 50 mm

-

No. of Slitting Lines:

-

3 - 5

-

Coil Weight (T):

-

10 T

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Zhongtuo

-

Voltage:

-

380v/50hz/3ph

-

Rated Power:

-

around 100Kw

-

Dimension(L*W*H):

-

25*7m

-

Weight:

-

18T

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

roll slitting machine

-

.line speed:

-

0-60m/min

-

Cutting thickness:

-

0.5-2.0mm

-

width:

-

500-1500(Max)

-

diagonal tolerance:≤±1mm/2000mm:

-

≤±1mm/2000mm

-

.length tolerance:

-

≤±0.5mm/2000mm

-

Type:

-

Shearing Machines

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

CE ISO

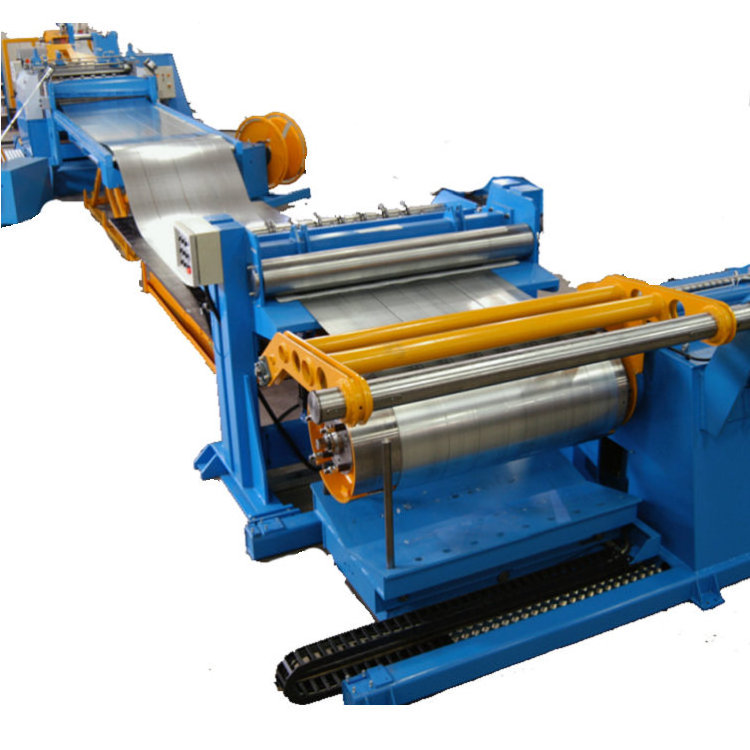

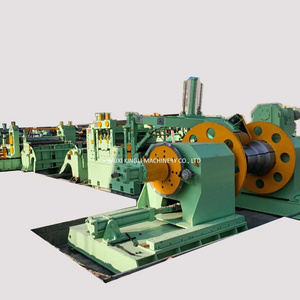

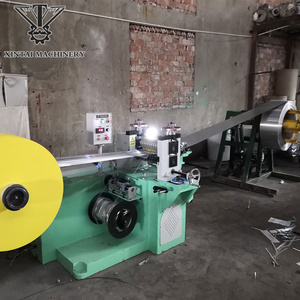

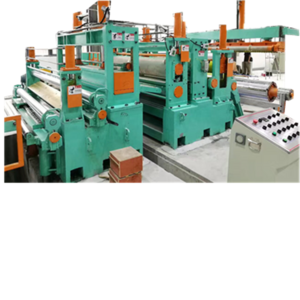

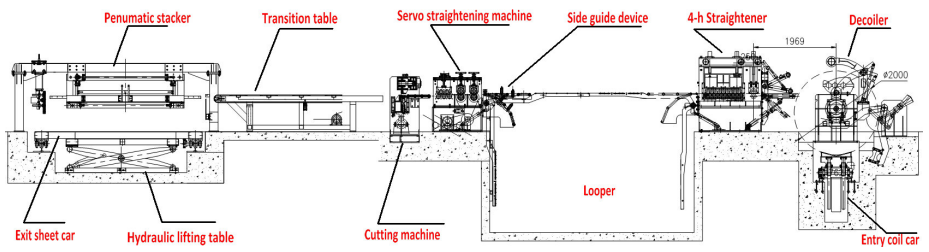

Steel coil slitting machine steel sheet slitting line metal slitting cutting machine

Introduction of steel sheet roll slitting machine :

roll slitting machine is a lengthways cutting production line, for cutting metal sheet stirp.

roll slitting machine can uncoil metal sheet strip coil, then slit(cut) the metal sheet strip longitudinal, then rewind the slitted metal sheet strips, for getting narrow metal sheet strip coils.roll slitting machine is for metal sheet strip coil cutting service center, press machine stamping punching, metal sheet strip processing,etc.

Technical Parameters of roll slitting machine:

1. Specifications:

a. applied to : HR,CR

b. Tensile strength:b≤500Mpa,S≤300Mpa

c. thickness:0.5-2.0mm

d. width:500-1500(Max)

e. coil ID: 508mm

f. coil OD:1600mm(Max)

g. weight :15T(Max)

h. diameter of leveling rollers: 65mm

i. distance of leveling rollers:70mm,

j. material of leveling roller:GCr15,hardness:HRC55-60

k. total weight of machines:around 30T

2. Finished products parameters:

a. diagonal tolerance:≤±1mm/2000mm

b. length tolerance:≤±0.5mm/2000mm

3. Other parameters :

a. power :380V/50Hz/3Ph

b. line speed:0-60m/min

c. capacity :around 100Kw

d. area of the whole production line(about) 25m(L)X7m(W)

e. people of operation: 1 technician and 2 general workers

f. color of the machines: grass green

Composed devices of roll slitting machine:

1.Hydrauliccoil car

2.Hydraulic decoiler

3.Slitting machine

4.Scrap winder

5.Tension stand

6.Hydraulic recoil

7.Unloaded car

8.Hydraulic control system

9.ELectric control system

work flow of roll slitting machine

details of roll slitting machine

|

Hydraulic de-coiler with car It adopts the hydraulic oil cylinder to make the decoiler expandable and fit to the inner diameter of coils. It is equipped with the cantilever. inner diameter: 508mm . The Max width:1500mm The capacity is 15Tons (max) |

|

pre-leveling machine It can straighten the rough plate and guide strip right after entering the process Mechanical structure: it is composed of two rows leveling roller, two rows middle supporting roller, 2 groups of supporting rollers, driving device, 2 pinch rollers and frame. Each roller both of ends drive with roller pin bearing, the working rollers can be adjusted the gap electrically which is controlled by 2 hand wheels to ensure the leveling quality. Driving model: driven by 55kw frequency control motor Roll process:hardened HRC55-60 -finishing grinding- hard chromium plating Automatic lubrication system |

|

Servo precision straightening machine It is controlled by servo electromotor and used to regulate for high speed feed and precise length control. The operation is done at the control table with programmable control. Drive model: 15 KW servo motor |

|

High speed Cutter 1). The width range :200--1300mm 2). The precious of the width:±1mm 3). The speed of slitting:50m/min 4). The width can be change. 5). Material of the slitting: Cr12MoV. Hardness of slitting blade:HRC5860. 6).slitting:2~3mm 6 lines. 7).quantity of blades:10 sets . 8).Width of side scrap:3-15mm 9).The precious of side scrap:±0.5mm 10).Quantity of side scrap:2 strips 11).Power of the slitting:37KW,1000r/min,with ZQ750 Reducer. |

|

Pneumatic stacker device The plates are piled pneumatically and PLC controls the lifting. Three 0.75kw motors drag to adjust the width and the length. It is equipped with the wind device which cooperates with the high pressure fan to prevent the sheets from friction. stress of air source: 0.4-0.6Mpa. The capacity:1m³ /min. |

|

Electrical system 1). Screen:3.2inch button screen 2). PLC:Delta |

The foundation engineering of the equipment

The seller will provide the buyer the foundation plan of the equipment in 60 days after signing contract.

The construction and monitoring of all the foundation engineering of the equipment are in the control of the buyer.

The foundation holes are reserved holes, to match the foot holes of equipment.

After the equipment has been installed, the buyer is responsible for the foundation hole irrigation mud.

Remark

1. In the guarantee equipment main technical parameters and installed level, the user and consultation, and manufacturing process has the right to modify some parameters

2. Seller needs to supply following items

(1) Mechanic al foundation installation drawing and production line arrangement as well as the operation manual.

(2) All the below spare parts are provided with the machine, any extra spares, that would be ready by customer self.