- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 Years

-

Flow:

-

20~29kg/h

-

Working Pressure:

-

2~20Mpa

-

Maximum Inlet Pressure:

-

40MPa

-

2nd Stage Output Pressure:

-

0.09-0.32Mpa

-

Vacuum Energy Level:

-

2nd stage

-

Working Voltage:

-

DV12~14

-

Appearance Dimension:

-

130*120*100mm

-

Output Pressure:

-

1.5~2.5bar

-

Working Temperature:

-

-40℃~120℃

-

Packaging Info:

-

134*120*104

Quick Details

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

H&N

-

Model Number:

-

TR01

-

Warranty:

-

1 Years

-

Flow:

-

20~29kg/h

-

Working Pressure:

-

2~20Mpa

-

Maximum Inlet Pressure:

-

40MPa

-

2nd Stage Output Pressure:

-

0.09-0.32Mpa

-

Vacuum Energy Level:

-

2nd stage

-

Working Voltage:

-

DV12~14

-

Appearance Dimension:

-

130*120*100mm

-

Output Pressure:

-

1.5~2.5bar

-

Working Temperature:

-

-40℃~120℃

-

Packaging Info:

-

134*120*104

|

Flow

|

20~29kg/h

|

|

|

||

|

Working Pressure

|

2~20Mpa

|

|

|

||

|

Maximum Inlet Pressure

|

40MPa

|

|

|

||

|

2nd Stage Output Pressure

|

0.09-0.32Mpa

|

|

|

||

|

Vacuum Energy Level

|

2nd stage

|

|

|

||

|

Working Voltage

|

DV12~14

|

|

|

||

|

Appearance Dimension

|

130×120×100mm

|

|

|

||

|

Output Pressure

|

1.5~2.5bar

|

|

|

||

|

Working Temperature

|

﹣40℃~120℃

|

|

|

||

|

Weight

|

1260g

|

|

|

||

|

Packaging Informationoperating

|

134×120×104mm

|

|

|

||

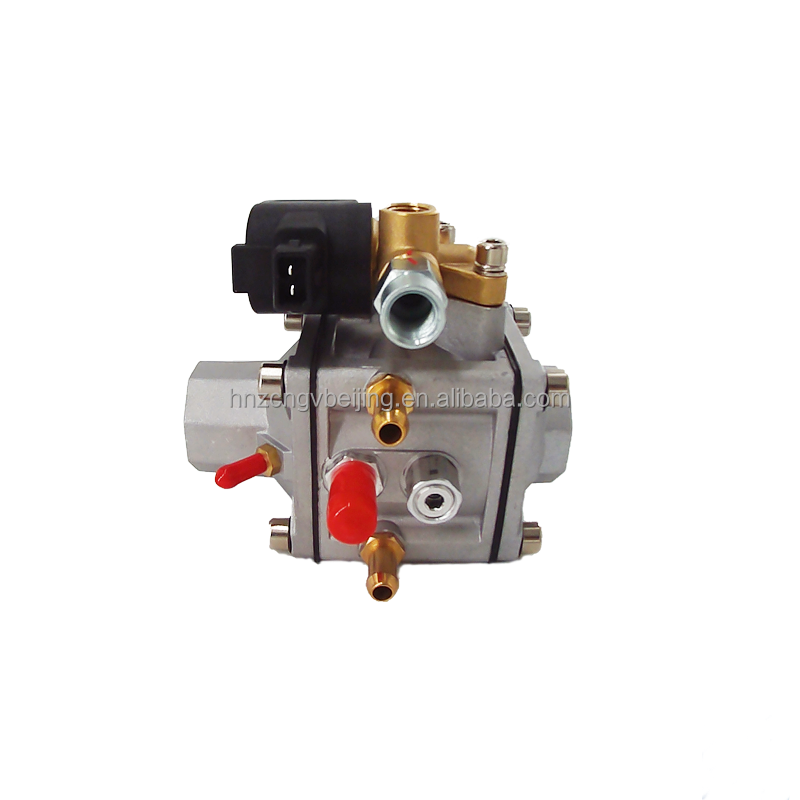

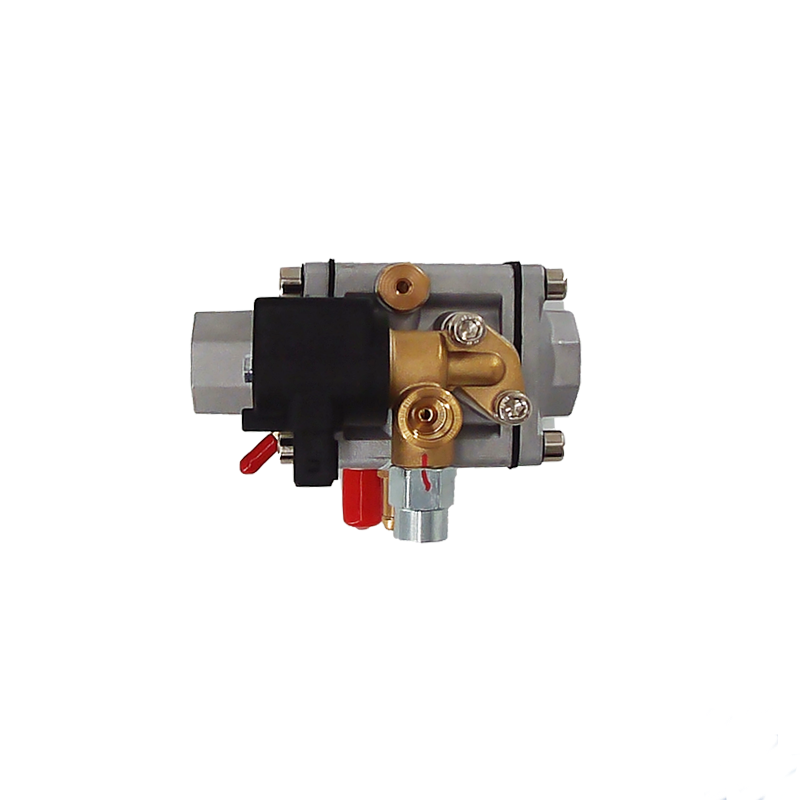

reducer

CNG/LPG pressure reducer, model TR04, is an electronic single stage reducer, suitable for sequential injection systems. it is equipped with an additional post-heating stage, suitable for medium-sized engines (up to about 140 KW).Compact and reliable, it is homologated in accordance with the ECE 67R-01 This reducer is equipped with a solenoid valve and an integrated filter unit atits inlet, in order to reduce the overall costs and permit an easier and faster installation. Outlet pressure is adjustable from 0.09 to 0.18 MPa (pressures calculated with the reducer disconnected from the engine).

System advantages (Main Functions)

1. Adopt high integration chip to improve the reliability and anti-interference performance of the controller;

2. The controller is highly compatible with the pressure reducer and the nozzle, and the software can be customized by customers;

3. The controller has self-protection function and gas parts protection function;

4. Advanced automatic calibration function and temperament self-learning algorithm;

5. Perfect fault diagnosis function and protection function;

6. Quality and control algorithm of the original system of the vehicle.

1. Adopt high integration chip to improve the reliability and anti-interference performance of the controller;

2. The controller is highly compatible with the pressure reducer and the nozzle, and the software can be customized by customers;

3. The controller has self-protection function and gas parts protection function;

4. Advanced automatic calibration function and temperament self-learning algorithm;

5. Perfect fault diagnosis function and protection function;

6. Quality and control algorithm of the original system of the vehicle.

Hot Searches

![[LLANO] Car AT12 Reducer Regulator style Auto Gas Conversion Kit CNG GNV GNC gas conversion kit](https://cdn.bestsuppliers.com/seo_products_img/llano/f93f091bee5832f3ad9faabdcf22aa45.jpg!/rotate/180/sq/300)