- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

RuiDa

-

Cutting Thickness:

-

Materials

-

Control Software:

-

CorelDraw/Ruida/Leetro/AutoCAD

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FST

-

Weight (KG):

-

1100 KG

-

Core Components:

-

laser power

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Laser power:

-

60w/80w/100w/130w/150w

-

Color:

-

Request

-

Laser tube:

-

Sealed CO2 Glass Tube

-

Function:

-

Cutting Nonmetal Materials

-

Model:

-

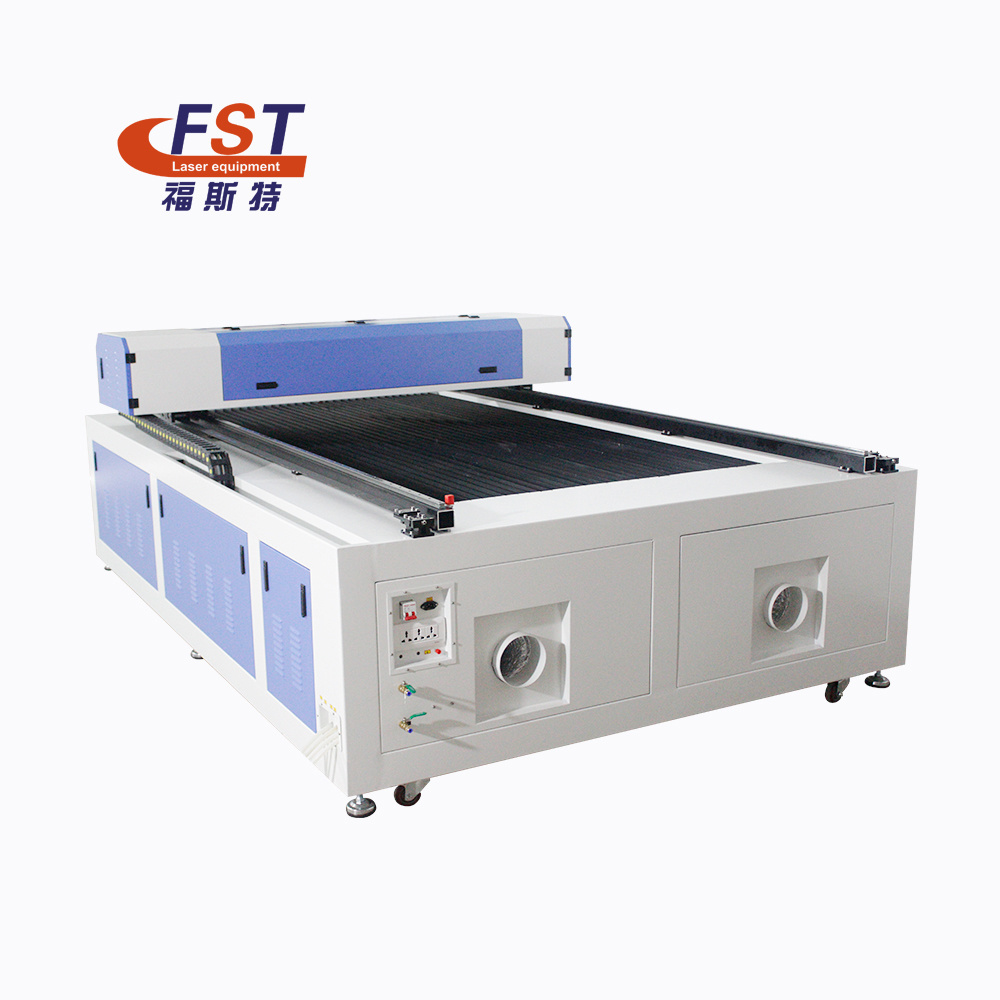

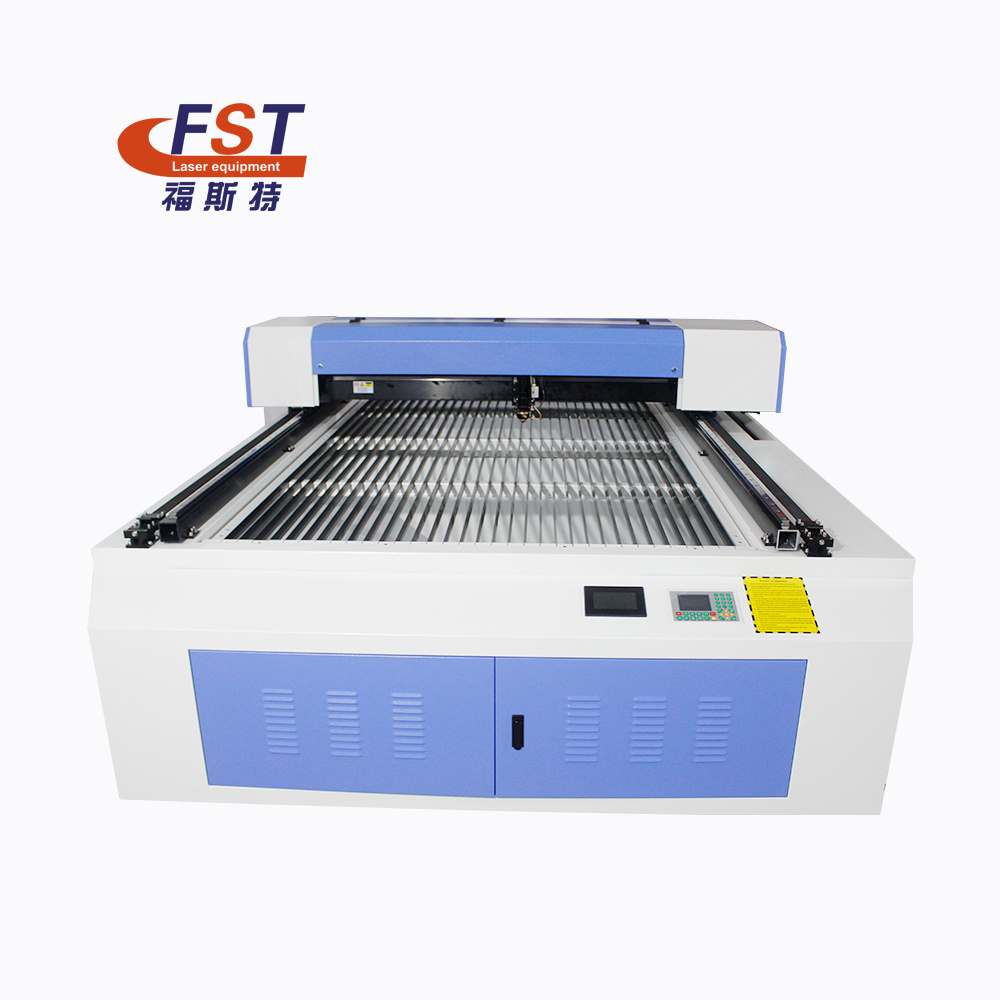

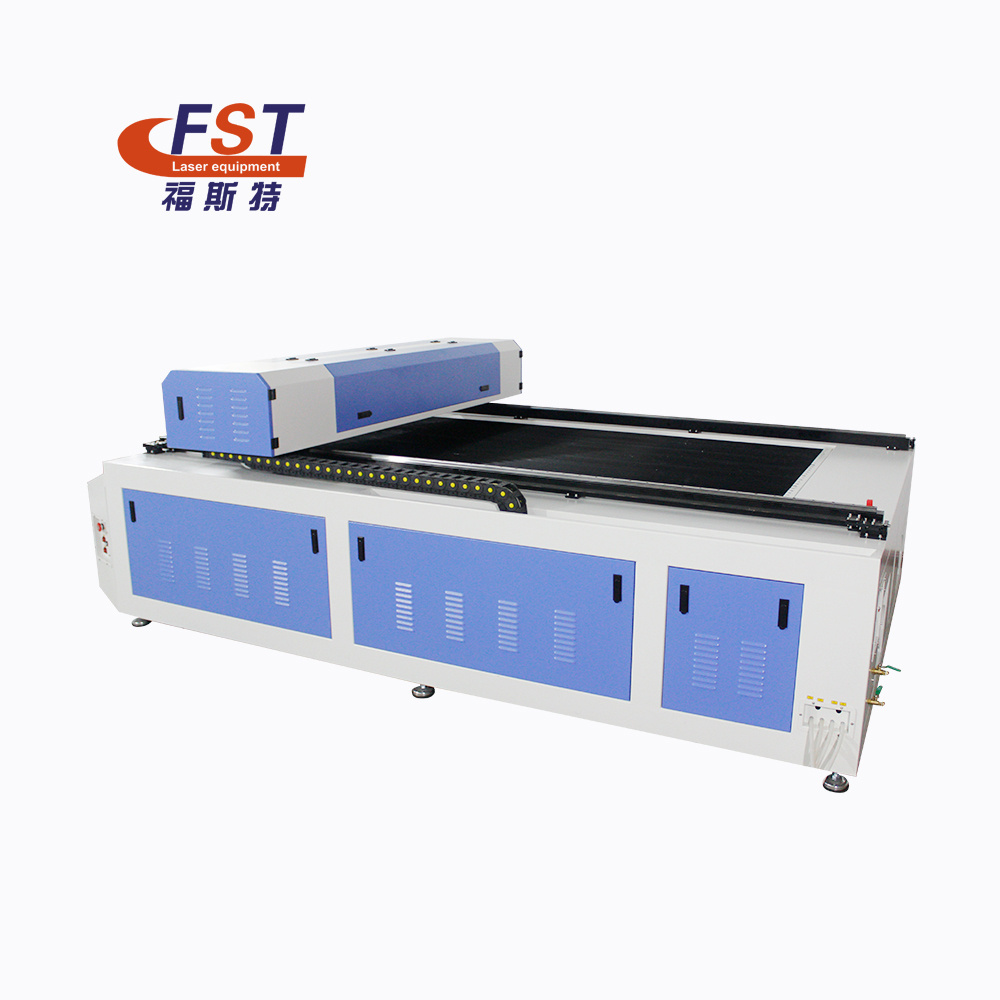

1325 Laser Cutting Machine

-

Working area:

-

1600*1000mm/1600*1200mm

-

Type:

-

Water Cooling CO2 Laser Cutting Machines

Quick Details

-

Laser Type:

-

CO2

-

Cutting Speed:

-

0-40000mm/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

RuiDa

-

Cutting Thickness:

-

Materials

-

Control Software:

-

CorelDraw/Ruida/Leetro/AutoCAD

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FST

-

Weight (KG):

-

1100 KG

-

Core Components:

-

laser power

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Laser power:

-

60w/80w/100w/130w/150w

-

Color:

-

Request

-

Laser tube:

-

Sealed CO2 Glass Tube

-

Function:

-

Cutting Nonmetal Materials

-

Model:

-

1325 Laser Cutting Machine

-

Working area:

-

1600*1000mm/1600*1200mm

-

Type:

-

Water Cooling CO2 Laser Cutting Machines

Product description

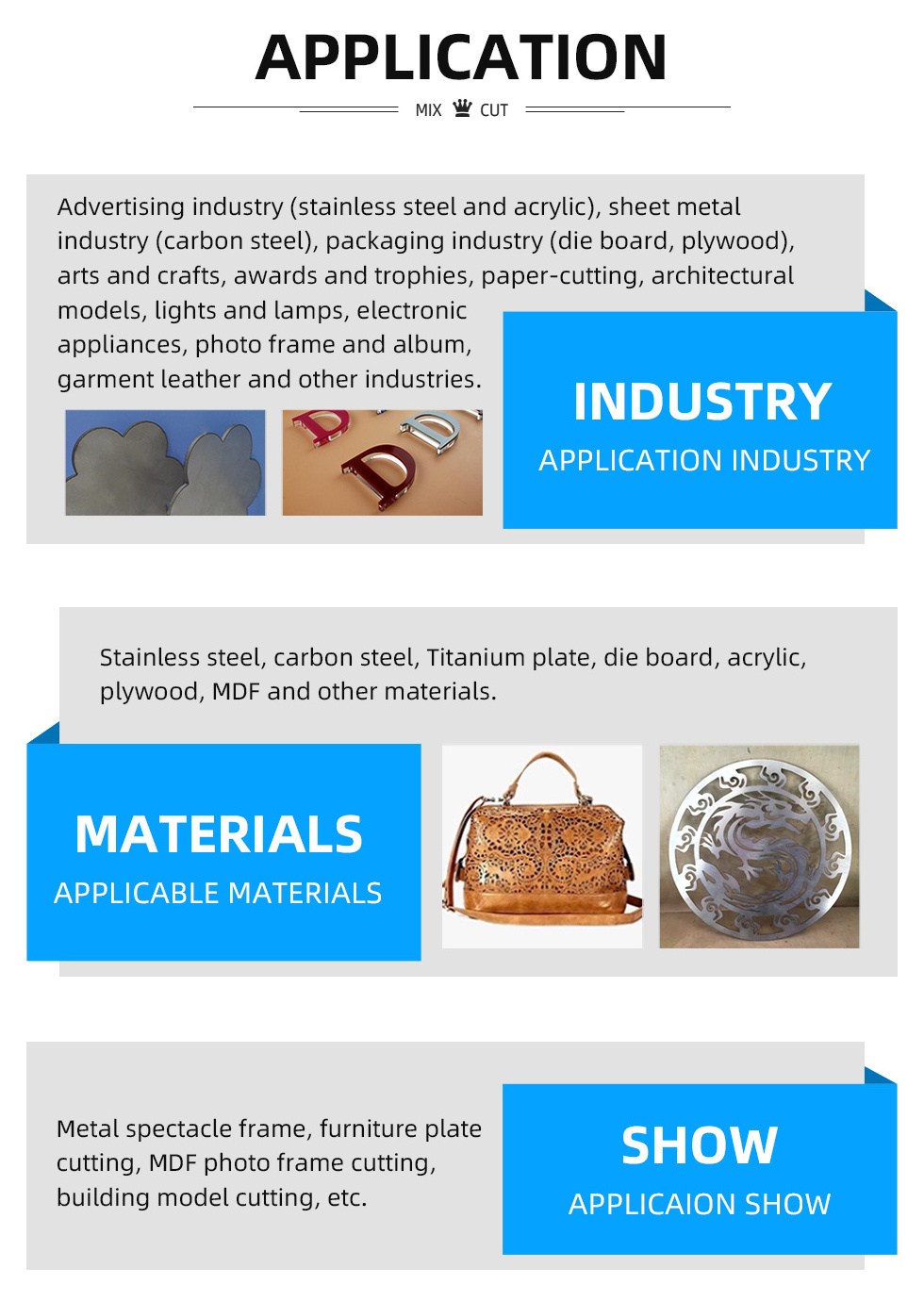

Application Industry

Details Images

Main configuration

Product Paramenters

|

Model

|

FST-1325

|

|

Laser type

|

Hermetic and detached CO2 laser tube

|

|

Worktable

|

Honeycomb or Aluminum knife

|

|

Engraving area

|

2500*1300mm

|

|

Laser Power

|

150W/180W/200W/300W

|

|

Cooling mode

|

Circulating-water-cooling

|

|

Power adjustment

|

0-100% controlling, no segment and adjusting by software

|

|

Machine control and drive

|

Speedy DSP controlling, stepper motor

|

|

Max engraving speed

|

60000mm/min

|

|

Max cutting speed

|

50000mm/min

|

|

Cutting Depth (Acrylic)

|

0-30mm

|

|

Resetting positioning accuracy

|

<0.01mm

|

|

Minimum Shaping Character

|

Chinese character: 1.5mm; crisscross-row: 1mm

|

|

Working voltage

|

AC220V 50Hz / 110V 60Hz

|

|

Dictate format

|

*.plt,*.dst,*.dxf,*.bmp,*.dwg,*.ai,*las,

Support AutoCAD,CoreDraw direct outputting

|

|

Controlling software language

|

English, Chinese

|

|

Working environment

|

Temperature: 0-45℃, Humidity: 5%-95%, and congeal-water removed

|

|

Machine Dimension

|

3210*2010*1160(mm)

|

|

Gross Weight

|

1100kg

|

|

|

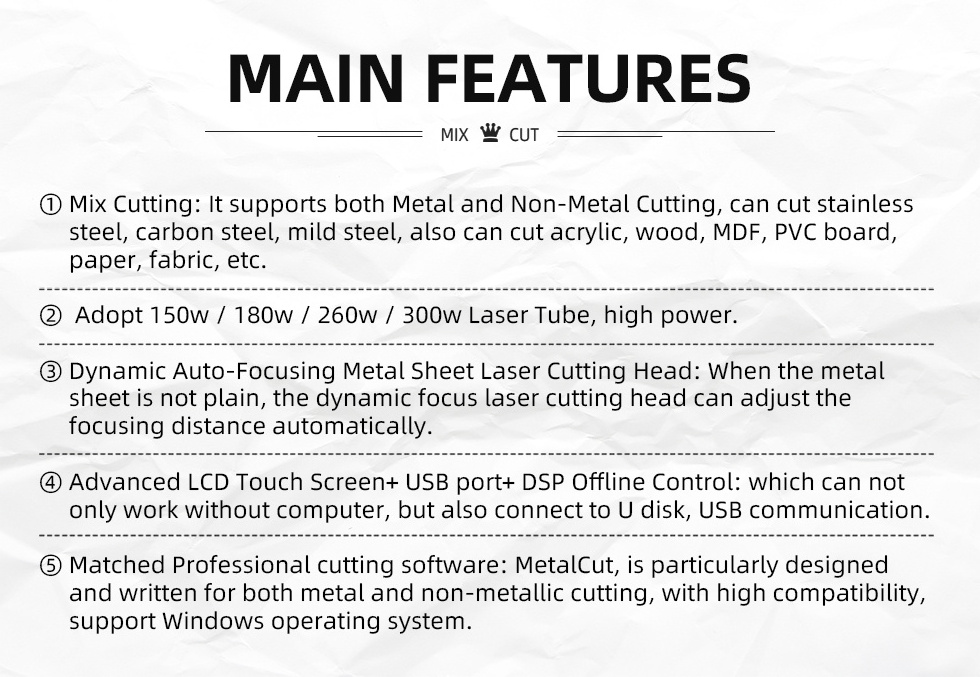

Co2 Mixed laser cutting machine

|

Fiber laser cutting machine

|

|

Laser power

|

150W ~ 300W co2 laser tube

|

1KW ~ 6KW Fiber laser source

|

|

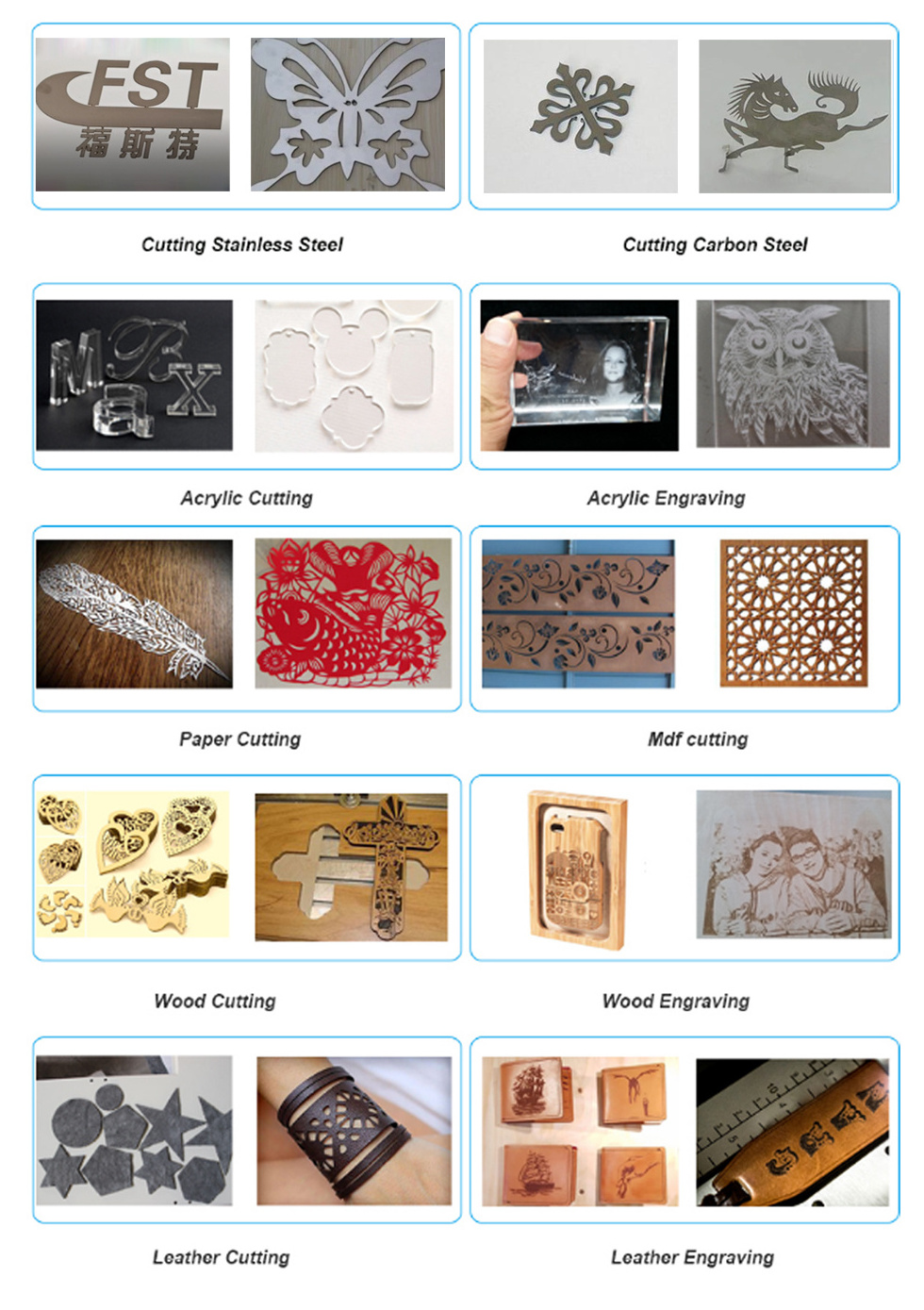

What material can be cut?

|

Non-Metal Cutting:

acrylic, wood, MDF, PVC board, paper, fabric, etc. Metal Cutting: stainless steel, carbon steel |

Just Metal Cutting:

stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, pickle plate, aluminum-plating Zinc plate, metallic copper and other metals. |

|

What materials cannot be cut?

|

Highly reflective metals, such as aluminum, copper, etc.

|

Non-metallic materials

|

|

stainless steel cutting thickness

|

0~3mm

|

0-20mm

|

|

Metal cutting speed

|

Slow than fiber laser cutting machine

|

Very fast: up to 5-10 times faster than Co2 mixed laser cutting machine

|

|

Auxiliary gas(Metal cutting)

|

Must be oxygen

|

Oxygen, nitrogen or air

|

|

Metal cutting effect

|

Not as good as fiber cutting machine

|

Smoother, best

|

|

Maintenance

|

Complexity: require periodic maintenance and part replacement.

|

Very simple: require little or no maintenance

|

|

Electrical efficiency

|

Low

|

High

|

|

Laser tube/source working life

|

10,000 hours

|

over 100,000 hours working life

|

|

Machine price

|

150W-300W Co2 Mixed:

Maybe 6,200.00-$9000.00/set

|

1Kw Fiber: Maybe 20,000.00-$24,000.00/set

|

Therefore, if you cut non-metals most of the time, and the time for cutting metals is not much, the precision requirements for cutting metals are not very high, and the budget is limited, we recommend that you choose the co2 mixed cutting machine, which is very suitable.

If you cut a large amount of metal, the cutting work is busy, or you need to cut highly reflective materials such as aluminum and copper, or the thickness of the cut metal exceeds 3mm, we strongly recommend that you choose a fiber laser cutting machine.

|

|

180W

|

300W

|

|

Stainless steel

|

0~1.5mm

|

0~3mm

|

|

Carbon steel

|

0~1.5mm

|

0~3mm

|

Product packaging

FeedBack

Our Service

1. warranty for 1 year.

2. Maintenance for the whole life.

3. We will provide the consumable parts at an agency price.

4. 24 hours online service, free technical support.

5. Machine has been adjusted before delivery, operation disk is included in the delivery. If there are any other questions, pls kindly tell me.

6.We have manual instruction and CD (Guiding Videos) for software Installation, operation and machine's using and maintenance

FAQ

Q1. Before sending me an inquiry on our CNC laser, it is better for you to provide me the following information

1)Your metal or non-metal material size. Because in our factory, we have different models according to the working area.

2)Your materials.

Metal/Acrylic/plywood/MDF?

3)You want to engrave or cut?

If cut, could you tell me your cutting thickness? Because different cutting thicknesses need different laser tube power and laser power supplier.

Q2. If we don't know how to use the machine, can you teach us?

Yes, We will send you a manual and guide video in English, it can teach you how to operate the machine. If you still can not learn how to use it, we can help you by "Teamviewer" online help software. Or we can talk by phone, email or skype

Q3.How long is the delivery time?

For standard machines, it would be 3-5 days; For non-standard machines and customized machines according to the client's specific requirements, it would be 7 to 10 days.

Q4. Quality Control:

The whole production procedure will be under regular inspection and strict quality control. The

complete machine will be tested to make sure they can work very well before being out of the factory.

Our machine passed CE Certificate, meet European and American standard, were exported to more than 100 Countries.

Q5. Do you arrange shipment for the machines?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

Hot Searches