- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2200*910*1200mm

-

Power (kW):

-

16

-

Weight (KG):

-

2000 kg

-

Panel Feed Speed(m/min):

-

30m/min

-

Usage:

-

Wood edge banding production

-

Name:

-

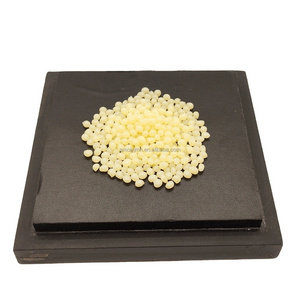

eva and pur glue for particle board plywood

-

Application:

-

Building Material Shops,Manufacturing Plant,Furniture boards

-

Keywords:

-

Wood Edge Banding Machine

-

Workpiece length:

-

≥ 100mm

-

Working thickness:

-

9-60mm

-

Working width:

-

>=60mm

-

Working Air Pressure:

-

0.6~0.8Mpa

-

Feeding speed:

-

18-28m/min

-

Color:

-

Customers Requirement

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

CHRYSO

-

Voltage:

-

380V, 380V 50HZ 3phase or customize

-

Dimension(L*W*H):

-

2200*910*1200mm

-

Power (kW):

-

16

-

Weight (KG):

-

2000 kg

-

Panel Feed Speed(m/min):

-

30m/min

-

Usage:

-

Wood edge banding production

-

Name:

-

eva and pur glue for particle board plywood

-

Application:

-

Building Material Shops,Manufacturing Plant,Furniture boards

-

Keywords:

-

Wood Edge Banding Machine

-

Workpiece length:

-

≥ 100mm

-

Working thickness:

-

9-60mm

-

Working width:

-

>=60mm

-

Working Air Pressure:

-

0.6~0.8Mpa

-

Feeding speed:

-

18-28m/min

-

Color:

-

Customers Requirement

Product Description

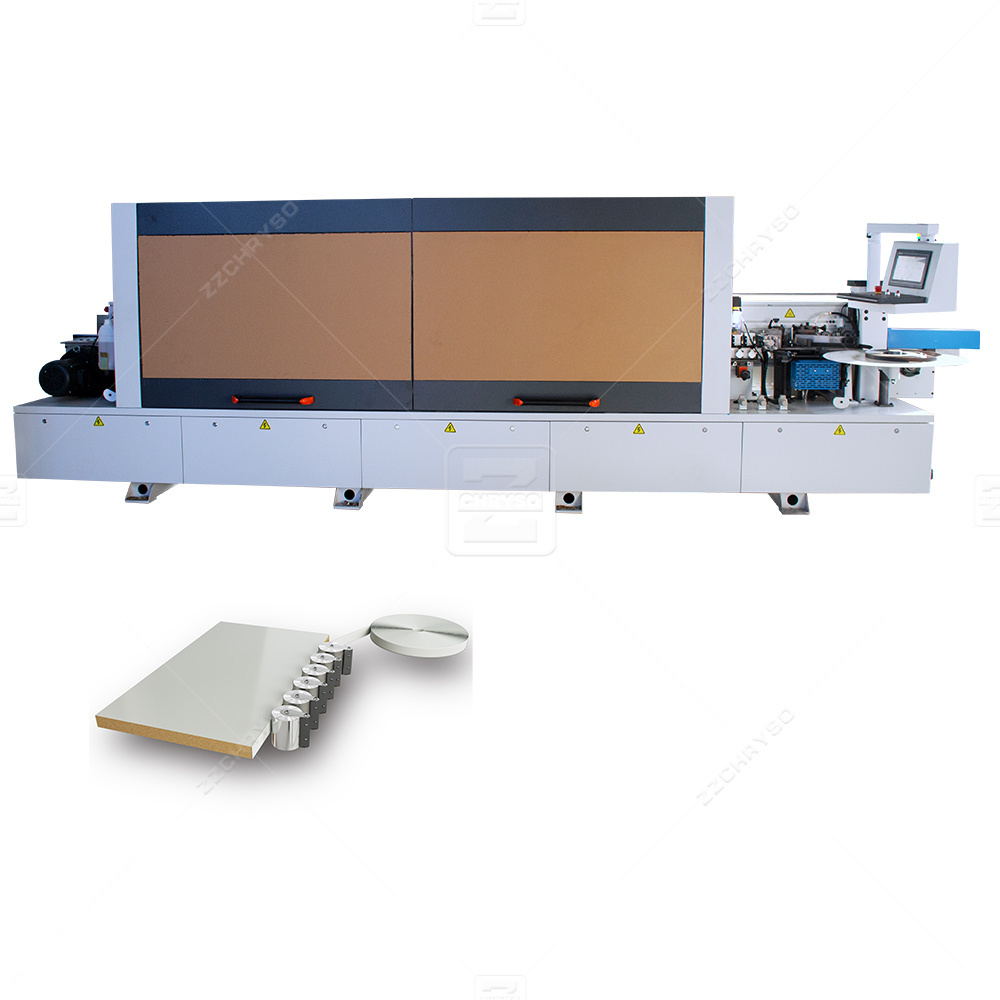

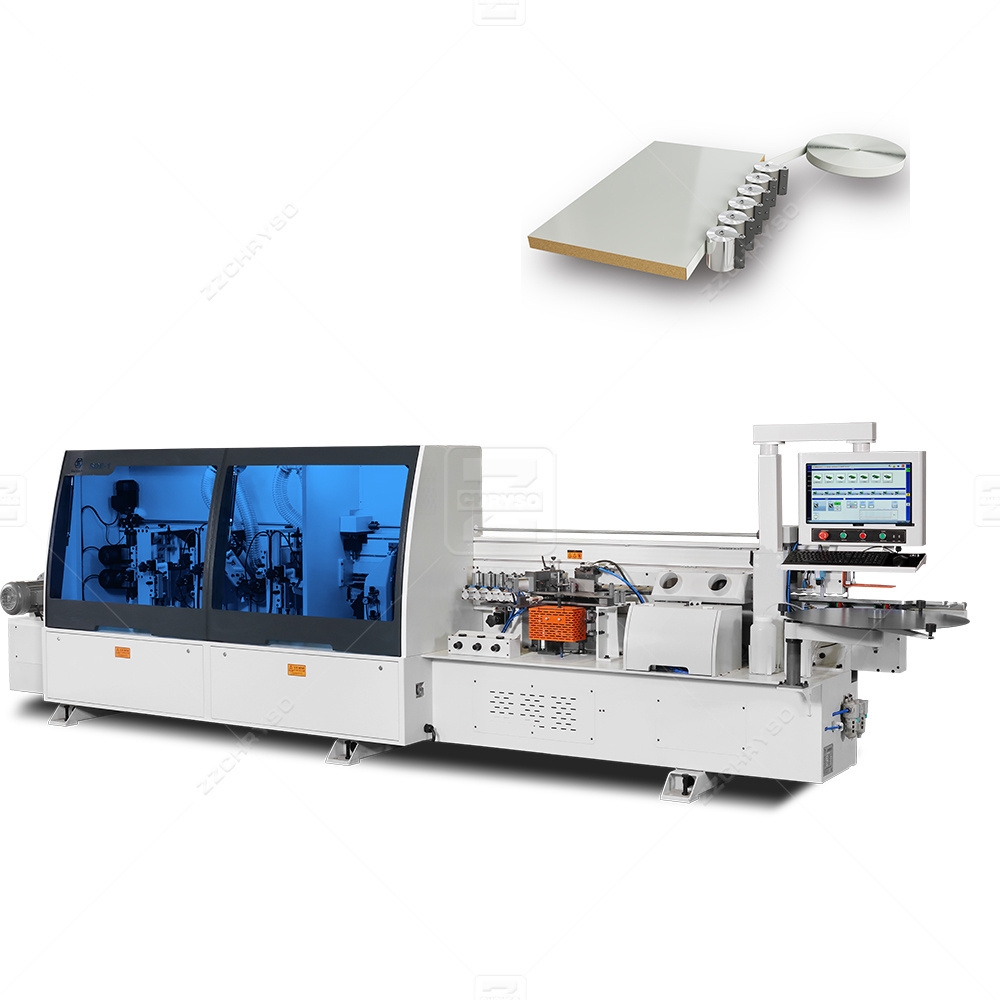

Edge banding machine

is used to cover the exposed sides of materials such as plywood, particle board or MDF, giving the appearance of a solid or more valuable material.These boards is widely used in banding edge of desks, cabinet, wardrobe and straight line furniture.The edge materials can be PVC, melamine, wood based works and so on.

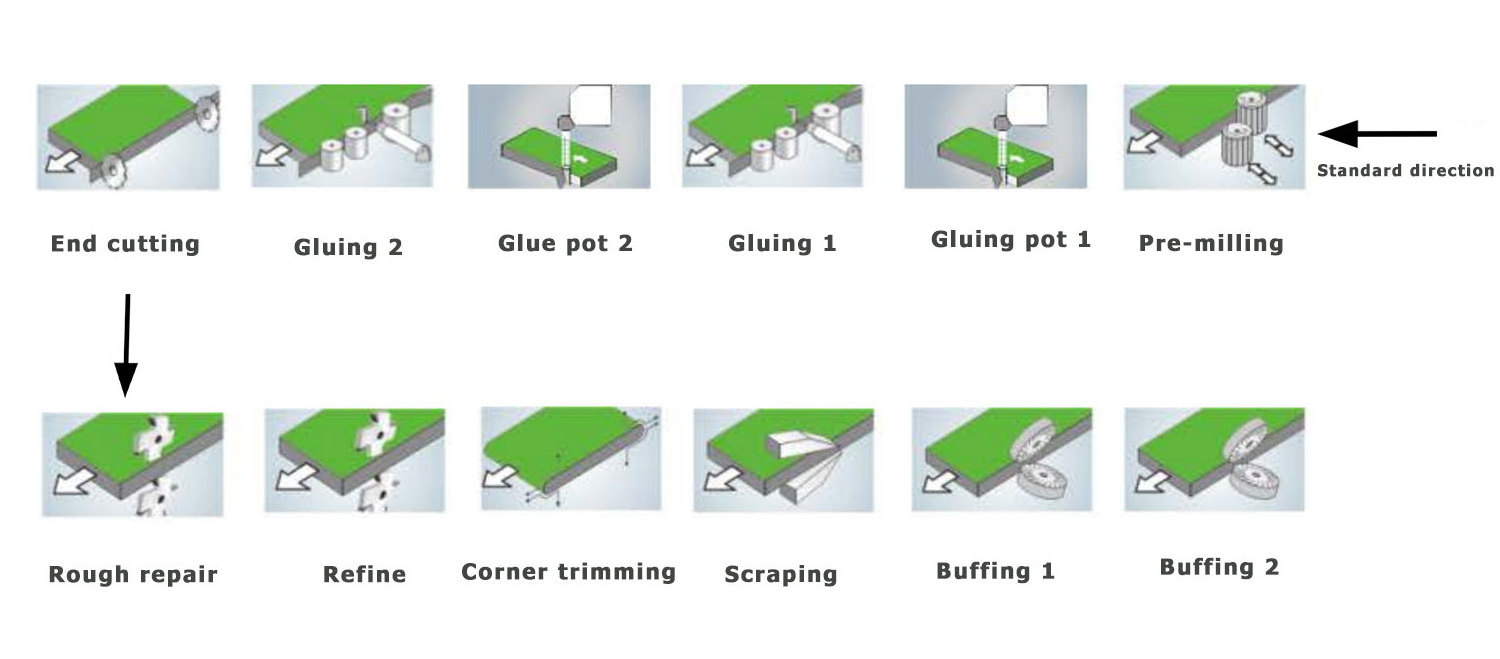

Work Steps

Edge banding effect display

Features:

1. Adopts patent designed appearance, reasonable engineering designed structure, brings you the safe and convenient operation of workers.

2. Adopts imported famous brands of key components.

3. Adopts precisely processed heavy-duty type frame and mechanical parts to ensure the stability and durability of machine.

4. Adopts electric pressure beam for ascending and descending by touch screen control.

5. Optional configurations are available to meet different production requirements.

6. Machine controlled by encoder and limited switch, failures can be highly reduced to ensure a smooth and rapid edge banding process. Remaining edge band can be also accurately controlled.

1. Adopts patent designed appearance, reasonable engineering designed structure, brings you the safe and convenient operation of workers.

2. Adopts imported famous brands of key components.

3. Adopts precisely processed heavy-duty type frame and mechanical parts to ensure the stability and durability of machine.

4. Adopts electric pressure beam for ascending and descending by touch screen control.

5. Optional configurations are available to meet different production requirements.

6. Machine controlled by encoder and limited switch, failures can be highly reduced to ensure a smooth and rapid edge banding process. Remaining edge band can be also accurately controlled.

Application

Specification

|

Model

|

CRS-51

|

CRS-53KS

|

CRS106

|

CRS-831

(double glue box)

|

CRS209TAS

(double glue

pot)

|

|

Total power

|

12kw

|

21kw

|

18.8kw

|

20KW

|

23.04KW

|

|

Feeding speed

|

18-20- 23

m/min

|

18-20- 23

m/min

|

18m-26m/min

(three speed)

|

18m-26m/min

(three speeds)

|

18m-28m/min

(feed speed 25 m/min when using tracking)

|

|

Edge strip

thickness

|

0.4-3mm

|

0.4-3mm

|

0.4-3mm

|

0.4-3mm

|

0.4-3mm

|

|

Workpiece thickness

|

9-50mm

|

9-50mm

|

10 - 60 mm

|

10 - 60 mm

|

10 - 60 mm

|

|

Workpiece length

|

≥ 100mm

|

≥150mm

|

150 mm (230mm when pre-milling)

|

150 mm (230mm when pre-milling)

|

150 mm (≥250mm when pre-milling)

|

|

Workpiece width

|

≥60mm

|

≥60mm

|

≥60mm

|

≥60mm

|

≥60mm

|

|

Working air pressure

|

0.7Mpa

|

0.7Mpa

|

0.65Mpa

|

0.6Mpa

|

0.6Mpa

|

|

Equipment size

|

5800*720*

1600mm

|

8110*720*

1610mm

|

5760*871*

1730 mm

|

9750*871*

1730 mm

|

10600*1000*

1670mm

|

Details Images

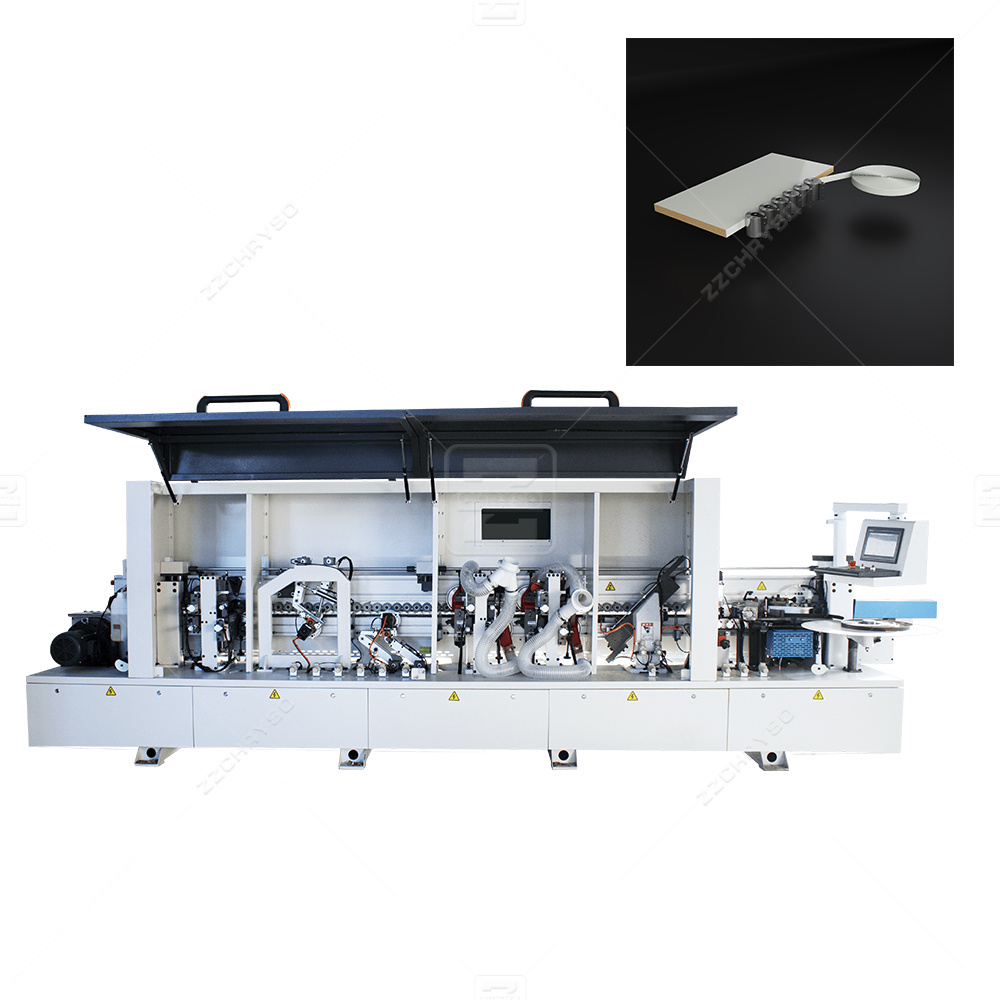

Pre Milling

After the iron cutting by the milling mechanism, various defects on the processed surface can be removed, so that the edge banding can reach the best state.

Automatic gluing system (optional)

Automatic glue adding function, timely and automatic glue supply, to ensure the normal operation of the equipment.

Six pressure rollers

The pressing force is strong, the edge banding is more suitable, and the excess hot melt glue is scraped off the board, so that the glue line is smaller and the edge banding effect is more perfect.

Fast edge trimming

Quickly cut front and rear edge bands with two saw blades aligned front and back to achieve high precision and high efficiency.

Rough repair + fine repair

Repair and remove the upper and lower excess parts of the edge banding of the processed board, and use the Die automatic follow and high-frequency high-speed motor and other mechanisms to ensure trimming The top and bottom of the board are flat and smooth.

Dual Track Trimming

Profile tracking trimming, up and down rounding device can make the end face of the plate It is smoother and more beautiful, improving production efficiency and edge banding effect.

Scraping

It is used to remove the ripple marks caused by the non-linear motion cutting process of trimming, so as to make the upper and lower parts of the board more smooth and tidy.

Polishing

Clean the processed board with a cotton polishing wheel to remove excess glue, Polish the edge to a smoother finish.

Product Display

Factory View

Hot Searches