<1>Into bottle way is air conveyor direct connection with Bottle dial .

<2>All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean .

<3>304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

<4> 304/316 stainless steel washing pump make the machine more durable .

- Product Details

- {{item.text}}

Quick Details

-

Capacity:

-

4000-35000BPH

-

Material:

-

SUS304/SUS316

-

Filling temperature:

-

Hot filling

-

Processing:

-

Washing,Filling,Capping

-

Structure:

-

Rotate

-

Bottle diameter:

-

50-90mm

-

Electric element:

-

Siemens&Schneider or by order

Quick Details

-

Packaging Material:

-

Wood

-

Place of Origin:

-

Jiangsu, China

-

Controlled by:

-

PLC (MITSUBISHI)

-

Capacity:

-

4000-35000BPH

-

Material:

-

SUS304/SUS316

-

Filling temperature:

-

Hot filling

-

Processing:

-

Washing,Filling,Capping

-

Structure:

-

Rotate

-

Bottle diameter:

-

50-90mm

-

Electric element:

-

Siemens&Schneider or by order

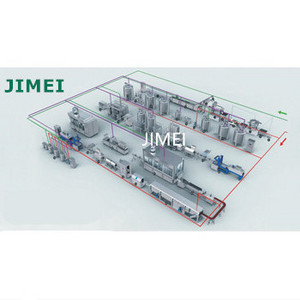

Product Application

1.This machine is used to fill juice, tea and other non-gas beverage.

2.All the machine part which contact with liquid is high quality stainless steel 304. The relative fittings are from international famous brand.

3.The automatic juice packaging and bottling machine was equipped with suspension type air conveyor and frequency control of motor speed.

4.This machine is comprised of rinsing, filling and capping system. Rinsing: grip the bottle neck, rotate filling plate, inverse bottle; internal rinsing and external spraying make bottles be cleaned completely. Filling: hot filling with holding bottle neck; the special backflow type of the filling valve can avoid leakage after filling and also control liquid level accurately. Capping: magnetic torque bottle holding type can minimize the cap damage rate and make the capping performance the best.

5.This machine owns the reasonable, stable and safe design. Under the condition that the bottle neck size is the same, only the output star wheel needs to be changed if bottles are different. It improves the efficiency a lot.

We are the automatic juice packaging and bottling machine manufacturer from China.

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Washing heads.

Filling heads.

<1> 304/316 Stainless steel high precision filling nozzle

<2> Filling volume adjustable in fine rank, same liquid level after filling

<3> All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

<4> 304/316 stainless steel filling pump

<5>Efficient spray nozzle rinse thoroughly and save water for flushing

Capping heads.

<1> Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

<2> All 304/316 stainless steel construction

<3> No bottle no capping

<4> Automatic stop when lack of bottle

<5>Capping effect is stable and reliable ,Defective rate ≤0.2% .