- Product Details

- {{item.text}}

Quick Details

-

Power:

-

11kw, basket centrifuge

-

Weight:

-

3200

-

Dimension(L*W*H):

-

2150*1500*2000mm

-

Name:

-

Automatic scraper bottom discharging Centrifuge

-

Application:

-

Solid Liquid Separation

-

Diameter of drum:

-

1000mm, centrifuge

-

Speed:

-

1000r/min

-

Working volume:

-

155L, centrifuge

-

Max. loading:

-

220kg, centrifuge

-

Separation factor:

-

560 centrifuge

-

Material of the centrifuge:

-

SS304

-

Advantage:

-

PLC control, easy operation

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shuangfa

-

Voltage:

-

220v/300v/380v/optional

-

Power:

-

11kw, basket centrifuge

-

Weight:

-

3200

-

Dimension(L*W*H):

-

2150*1500*2000mm

-

Name:

-

Automatic scraper bottom discharging Centrifuge

-

Application:

-

Solid Liquid Separation

-

Diameter of drum:

-

1000mm, centrifuge

-

Speed:

-

1000r/min

-

Working volume:

-

155L, centrifuge

-

Max. loading:

-

220kg, centrifuge

-

Separation factor:

-

560 centrifuge

-

Material of the centrifuge:

-

SS304

-

Advantage:

-

PLC control, easy operation

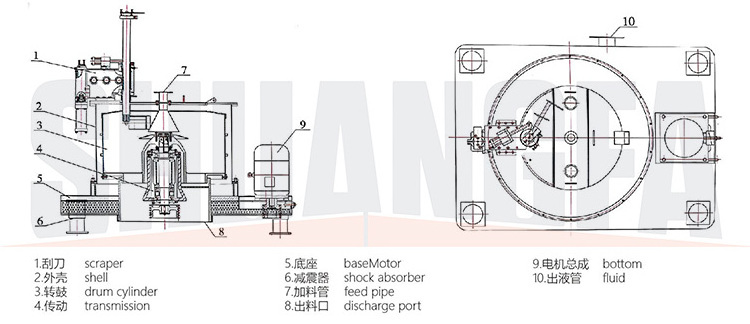

Product Description

PGZ series scraper bottom discharging basket centrifuge machine is designed with fixed cover, suitable for the separation of toxic, volatile, inflammable and explosivematerials.

Working Principle of Automatic Scraper Bottom Discharge Basket Centrifuge:

The automatic scraper bottom discharging basket centrifuge is the automatic vertical centrifuge separation machine.

The motor drives the basket to rotate at a high speed through the belt, and the materials to be separated enter into the centrifuge basket at a high speed through the feeding system under the control of the pre-programmed program. Under the action of the centrifugal field, the material will be filtered through the filter media (fiter cloth/screen), the liquid phase will be discharged through the liquid outlet, and the solid phase will be retained in the basket. The material detection device will detect the filing level of the material in real time. When the basket cake reaches the loading capacity specified by the machine, it stops feeding. The filter cake is then washed and dried. After the cake meets the dehydration requirements, the centrifuge reduces to the scraping speed, and the scraper removes the cake under the hydraulic (pneumatic) drive, and then the cake is discharged through the solid discharge port of the centrifuge at the lower part.

Structure of Automatic Scraper Bottom Discharge Basket Centrifuge:

Application of Automatic Scraper Bottom Discharge Centrifuge:

Automatic scraper bottom discharging basket centrifuge can be used for solid-liquid separation of suspension materials with granular solid phase, and also for solid-liquid separation of fibrous materials, especially for high viscosity, fine particle size, toxic and fiammabie materials.

For example: gypsum, ammonium sulfate,mirabilite, copper sulfate, potassium chioride, borax, dyes, pigments,resins, pesticides and other chemical raw materials, salt,food additives, starch, sugar, chemical condiments and other foods, antibiotics, vitamins and others, as well as minerals,environmental protection industries in the solid and liquid phase filtration and separation.

Detailed Images

Machine base & damping system of basket centrifuge

Flat structure, rigid connection between the casing and the base plate, fully bearing the casing;

The damping system adopts the liquid damping support system with springs, good vibration resistance;

Convenient and fast installation and movement, operation more convenient.

Big cover structure of basket centrifuge

Fixed cover,

suitable for the separation of toxic, volatile, inflammable and explosivematerials.

With the feeding and washing pipe, observsion mirror, an explosion-proof lamp,scraping device, and the material level detector.

Material: SS304, SS316L etc.

Outlet of basket centrifuge

Scraper Bottom discharging way.

Motor part of basket centrifuge

Equipped with explosion-proof energy-saving motor and C-type triangular belt;

With motor protective covers to ensure safe operation.

Scraper part of basket centrifuge

Automatic scraping device, optimized scraper cutting angle, reduces scraping resistance and makes scraping smoother; works smoothly and reliably.

Material: SS304, SS316L etc.

distributing device of basket centrifuge

The angle design of the material tray of the distributor is reasonable, which can evenly arrange the materials to the bottom of the drum and the position of the drum cover.

Speed is adjustable.

Material:Material: SS304, SS316L etc.

Electric control system of basket centrifuge

Siemens PLC control, ABB frequency converter.Famous brand, quality guarantee.Simple operation.

Equipped with protection functions such as overspeed protection and motor overload and overheating protection.

Drum part of centrifuge separator

The centrifuge drum is welded as a whole and has undergone strict dynamic balance testing with high balance accuracy, the welding seam of the drum is 100% non-destructive tested, with a smooth transition and no cleaning dead corners;

Material: SS304, SS316L etc.

Filter bag of centrifuge separator

Different material filter bag for choice, for example, Polypropylene filter cloth, polyester filter cloth, nylon etc, suitable for different pulp and meet separation requirements.

Customized Production Service

Customzized configuration of Basket centrifuge:

According to the PH and temperature of pulp to be processed, select the different anti corrosion treatment:

Stainless steel lined with Halar

Carbon steel coated with PP

Size Information

|

Model

|

Diameter of basket

(mm)

|

Basket volume(L)

|

Max.Load

(Kg)

|

Max.speed

(r/min)

|

Separation factor

|

Power

(Kw)

|

Dimension

(L*W*H)(mm)

|

|

PGZ800

|

800

|

100

|

135

|

1200

|

645

|

7.5

|

1880*1350*2280

|

|

PGZ1000

|

1000

|

185

|

250

|

1000

|

560

|

11

|

2150*1500*2000

|

|

PGZ1250

|

1250

|

310

|

420

|

960

|

645

|

22

|

2400*1780*2550

|

|

PGZ1500

|

1500

|

640

|

860

|

880

|

650

|

37

|

3100*2180*2930

|

|

PGZ1600

|

1600

|

800

|

1000

|

800

|

647

|

45

|

3100*2280*3050

|

Related Products

Packing & Delivery

Company Introduction

Sales Service & FAQ

Sales Service

1, Pre-sale services:

We will happily assist you in getting the information you need to make a decision on which products best fit your needs.We want you to feel good about your purchase.

We can design and manufacture products as per your special requirements.If required, we can train your technical personnel for you.

2, Services during the sale:

We strictly adhere to the principle of "the customer first".Your needs and concerns will be addressed to your complete satisfaction.

We can help clients to draft solutions to their specific situations.

3, After-sale services:

Our products are all guaranteed for a full year. During this period, if there is any quality problem, we repair it free of charge.

If there is any problem, we will take measures to solve it immediately,on-site.technical exchanging is also provided for you.

FAQ

1, What products you provide?

Kinds of centrifuge, kinds of filter press, ,vacuum belt filter, round filter press machine, stainless steel filter machine, filter plate and filter cloth, wine filter etc.

2, What's your MOQ?

We will indicate the MOQ for each item in the quotation list, generally the MOQ is 1set.

3, What is the payment terms?

TT and L/C are acceptable and TT will be more appreciated.

30% advance payment by T/T, 70% to be paid before delivery of goods by T/T.

4, What is the machine warranty?

All the machines from my factory have 1 year warranty.

5, Is on site installation & commissioning available?

Yes.

6, What data you need for selecting the model of centrifuge?

Generally, we need know the processing capacity, solid content, particle size of solid, the name of pulp to be processed, PH of pulp etc.

Hot Searches