- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110 - 480 v

-

Dimension(L*W*H):

-

22 x 2 x 4 m

-

Weight:

-

3000 kg

-

Product Name:

-

Floating Fish Feed Production Line

-

Material:

-

Stainless Steel

-

Main Extruder:

-

Twin screw extruder.

-

Automatic Grade:

-

Full Automatic

-

Capacity:

-

100 kg/h - 3.5 t/h

-

Motor:

-

Siemens, ABB or Chinese brand

-

Electric elements:

-

Siemens, ABB or Chinese brand

-

Operation:

-

Easy to operate

-

Application:

-

Goldfish, carp, the ornamental fish, shrimp, etc.

-

After-sales Service Provided:

-

Field maintenance and repair service

Quick Details

-

Max. Capacity:

-

1ton/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Kelid

-

Voltage:

-

110 - 480 v

-

Dimension(L*W*H):

-

22 x 2 x 4 m

-

Weight:

-

3000 kg

-

Product Name:

-

Floating Fish Feed Production Line

-

Material:

-

Stainless Steel

-

Main Extruder:

-

Twin screw extruder.

-

Automatic Grade:

-

Full Automatic

-

Capacity:

-

100 kg/h - 3.5 t/h

-

Motor:

-

Siemens, ABB or Chinese brand

-

Electric elements:

-

Siemens, ABB or Chinese brand

-

Operation:

-

Easy to operate

-

Application:

-

Goldfish, carp, the ornamental fish, shrimp, etc.

-

After-sales Service Provided:

-

Field maintenance and repair service

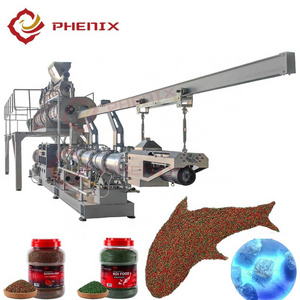

Floating Sinking Fish Feed Machinery Double Screw Fish Feed Production Line Extruder For Fish Food

Equipment:

Fish feed making machine

is used for processing for dogs and cats (pet food), birds, piglets, frogs, sinking and floating aquatic feeds for fish. Which is high and new technical program as to catch the developing pet food market. CE certificate best price floating aquarium fish feed pellet food making machine mainly use maize, fish powder, meat powder and some food additive as main raw material, through mixing, extruding, roasting, flavoring to get the final puffed pet food.

This line is fully automatic, high capacity and with different of shapes. It can produce such as cat food, dog food, fish food, bird food and so on.

a. Raw Materials: adopts corn flour, fish meal as raw materials

b. Products: different shapes are made by adjusting the dies from extruder

c. Capacity: 140 - 160kg/h, 240 - 260 kg/h, 500 - 600 kg/h, 1ton---3ton/h

d. Flow chart:

Mixing system---Extrusion system---Drying system---Flavoring system---Packing system

e. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers’ Local voltage according to different countries

f. Machines Materials: All the machines are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function

e: Equipment list

Mixer → Screw Conveyor → Extruder → Air conveyor → Dryer → Hoister with Flavor → Oil Sprayer → Roller

|

Model |

KLD65 |

KLD70 |

KLD85 |

KLD95 |

|

Installed Power |

76Kw |

95Kw |

178Kw |

280Kw |

|

Production Capacity |

140- 160Kg/h |

240- 260Kg/h |

500- 600Kg/h |

1000Kg- 1200Kg |

|

Dimension |

1600*1800*2000mm |

1800*2000*2200mm |

2500*2600*3000mm |

3000*3200*3500mm |

Mould

Samples

Packing:

Inside: plastic bag.

Outside: wooden case (adopt the wooden case or wooden pellets depended on clients' requirement).

Shipping:

Train, express, or upon clients’ demands.

Before sale services:

1.Provide the free consultation of the equipment.

2.Provide the standard device and the flow chart.

3. According to the clients’ special requirement, offering the reasonable plan and free design helping to select the equipment.

Services during the sales:

1.Help client design the factory and offering professional advice, free engineering drawing for the factory layout.

2.Welcome to visit our factory or the domestic clients’factory.

3.Inspect the machine before leaving the factory.

After sale services:

1. Oversea install and debug the equipment.

2. Train the first-line operator.

3. Provide the basic formula

4. Operation/ Service/ Maintenance Manual: Provided In English.

5. We will provide 1-2 engineer to the client's factory for the installation and training. The client need provide room, food, round-trip transportation, visa fee and a nominal daily subsidy per person.