- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Vansen

-

Dimension(L*W*H):

-

1110*340*980mm

-

Weight:

-

200kg

-

Product name:

-

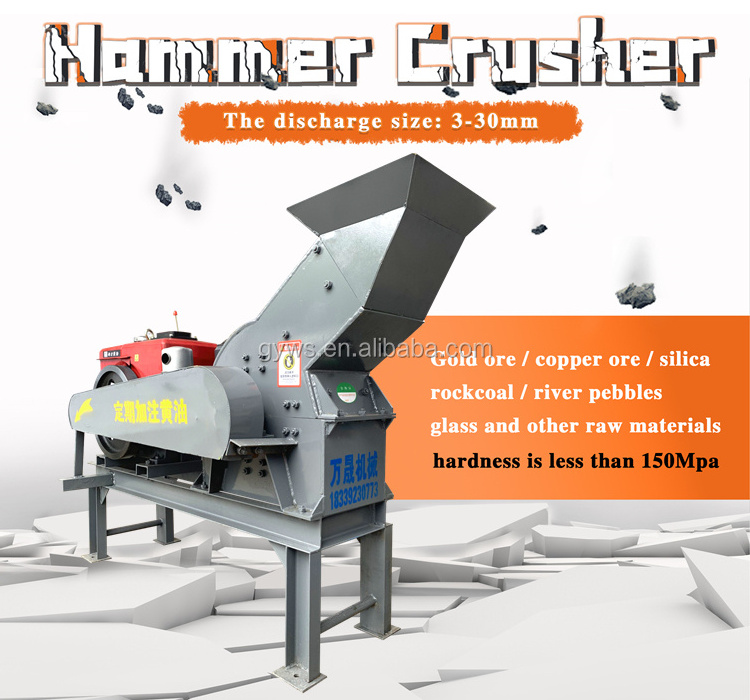

Hammer crusher

-

Keyword:

-

Pc350x200 Hammer Crusher

-

Model:

-

Pc350x200

-

Color:

-

Customizable

-

Installation:

-

Under Engineer's Guide

-

Processed Materials:

-

glass bottle

-

Feeding size:

-

60mm

-

Discharge size:

-

5mm

-

Hammers:

-

9

-

Wearing parts:

-

Hammer

Quick Details

-

Application:

-

Glass processing plant

-

Capacity(t/h):

-

10

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Vansen

-

Dimension(L*W*H):

-

1110*340*980mm

-

Weight:

-

200kg

-

Product name:

-

Hammer crusher

-

Keyword:

-

Pc350x200 Hammer Crusher

-

Model:

-

Pc350x200

-

Color:

-

Customizable

-

Installation:

-

Under Engineer's Guide

-

Processed Materials:

-

glass bottle

-

Feeding size:

-

60mm

-

Discharge size:

-

5mm

-

Hammers:

-

9

-

Wearing parts:

-

Hammer

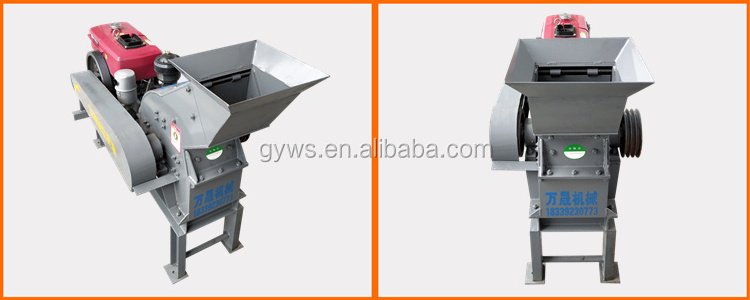

Product Display

For sale hammer crusher for gold mining small rock crusher

Mining crushing equipment Slag small diesel power for Gold mining plant

is suitable for crushing minerals of various brittle materials, such as coal, gypsum, alum, brick, limestone, etc.The compressive strength of the material shall not exceed 1000 kg force/cm 2 and the humidity shall not be more than 2%.

Parameter

|

Type number

|

PC 350*200

|

|

Size of feeding port (mm)

|

0-80

|

|

Maximum feed size (mm)

|

80

|

|

Adjustment range of discharge port (mm)

|

0-25

|

|

Processing capacity (T /h)

|

1-3

|

|

Eccentric shaft speed (R /min)

|

750

|

|

Diesel Power (hp)

|

8

|

|

Total weight (t)

|

0.22

|

|

Overall dimension (l * w * h) (mm)

|

1300*340*1200

|

Product details

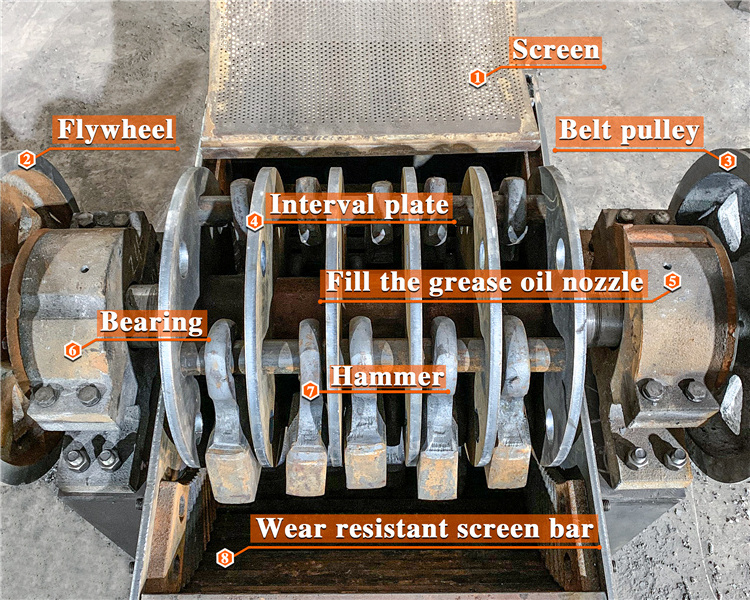

1. According to the hardness of the material, the hammer head replacement cycle is 3-10 days, the sieve bar replacement cycle is 2-3 months, and the service cycle of other vulnerable parts is 4-6 months.

2. When in use, add 500 ml butter to the bearing every 8 hours.

3. The discharging screen can use circular mesh screen or wear - resistant screen. The circular mesh screen is thin, the discharging is uniform, and the screen is thick, so it is more wear - resistant.

Raw materials

Product features

1. Working hammer head, casting with new technology, with wear resistance and impact resistance.

2. Can adjust the required granularity according to customer requirements.

3. Hammer to break the structure seal of the body, and solve the dust pollution and dust leakage of the body in the crushing workshop.

4. The overall design is beautiful, compact structure, less wearing parts, convenient maintenance and other advantages, is to upgrade the replacement products.

5. Compact structure, beautiful appearance, good wear resistance and easy maintenance.

2. Can adjust the required granularity according to customer requirements.

3. Hammer to break the structure seal of the body, and solve the dust pollution and dust leakage of the body in the crushing workshop.

4. The overall design is beautiful, compact structure, less wearing parts, convenient maintenance and other advantages, is to upgrade the replacement products.

5. Compact structure, beautiful appearance, good wear resistance and easy maintenance.

Electric motor or diesel engine drives the hammer crusher’s rotor to rotate at high speed in the crushing chamber. Material from the upper feed into the machine, high-speed hammer crushing the material. At the bottom of the rotor, a sieve plate is arranged. Particles smaller than the size of the sieve hole are discharged through the sieve plate. The coarse particle resistance larger than the size of the sieve hole remains on the sieve plate and continues to be beaten and ground by the hammer. Finally, the material is discharged from the hammer crusher through the sieve plate according to the required size.

Our Company

Gongyi Vansen Machinery and Equipment Co., LTD.

has gathered a large number of high-quality management talents and skilled scientific research elites. After years of hard exploration, we have established a complete and effective service system, and built an experienced service team. We not only provide free site planning, design and installation basic drawings and flow charts, but also provide professional technical training for customers, and send technicians to guide installation and commissioning of equipment on site.

Our Factory

Packing and delivery

Certificate

FAQ

Q1: Are you trading company or manufacturer?

A1:We are professional manufacturer, and our factory mainly produce crushing and milling equipment, wood crushing

equipment,construction equipment, brick production equipment, etc. Our products have been exported to more than 50 countries of Asia, South America, Africa, and get a good reputation in the world.

Q2: Installation?

A2:Our senior engineer will supply installation and training service on-line or on-site.

Q3: What about Warranty?

A3:Vansen Machinery grants our customers a twelve-month-period warranty from the date of delivery for machines exported from us.During the warranty period, in case any defect of material or workmanship occurred with spare parts in normal operation, we will at our discretion replace or repair the defective parts freely.

Q4: What about After-sale service?

A4:All equipment produced by Vansen is of the highest standard and our customers rarely experience mechanical failures. If there are

any problems, our engineers and technicians will respond with in 12 hours of customer notification.

Q5. For providing you the right model, we need to know the following information:

A5:

(1)* What is the raw material for the production line?

(2)* What is the capacity per hour you required?

(3)* What is the maximum input size of the raw material?

A1:We are professional manufacturer, and our factory mainly produce crushing and milling equipment, wood crushing

equipment,construction equipment, brick production equipment, etc. Our products have been exported to more than 50 countries of Asia, South America, Africa, and get a good reputation in the world.

Q2: Installation?

A2:Our senior engineer will supply installation and training service on-line or on-site.

Q3: What about Warranty?

A3:Vansen Machinery grants our customers a twelve-month-period warranty from the date of delivery for machines exported from us.During the warranty period, in case any defect of material or workmanship occurred with spare parts in normal operation, we will at our discretion replace or repair the defective parts freely.

Q4: What about After-sale service?

A4:All equipment produced by Vansen is of the highest standard and our customers rarely experience mechanical failures. If there are

any problems, our engineers and technicians will respond with in 12 hours of customer notification.

Q5. For providing you the right model, we need to know the following information:

A5:

(1)* What is the raw material for the production line?

(2)* What is the capacity per hour you required?

(3)* What is the maximum input size of the raw material?

Hot Searches