- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

0.5-1ml

-

Voltage:

-

AC110-200V

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

KAPACK

-

Dimension(L*W*H):

-

2100*1500*800mm

-

Weight:

-

260 KG

-

Product name:

-

KAPACK Liquid Filling Line

-

Material:

-

Stainless Steel 304/316

-

Filling range:

-

5-5000 ml (can be adjust with the filling range)

-

Filling accuracy:

-

≤1%

-

Advantage:

-

PLC+English panel control,adjust all on screen,very simple

-

Operate:

-

automatic dispenser alcoholic gel

-

Filling volume:

-

5ml-5000ml

-

Function:

-

glass plastic bottle sealing and filling machine

Quick Details

-

Machinery Capacity:

-

8000BPH, 6000BPH

-

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice, bottle filling sealing and packaging equipment

-

Filling Accuracy:

-

0.5-1ml

-

Voltage:

-

AC110-200V

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

KAPACK

-

Dimension(L*W*H):

-

2100*1500*800mm

-

Weight:

-

260 KG

-

Product name:

-

KAPACK Liquid Filling Line

-

Material:

-

Stainless Steel 304/316

-

Filling range:

-

5-5000 ml (can be adjust with the filling range)

-

Filling accuracy:

-

≤1%

-

Advantage:

-

PLC+English panel control,adjust all on screen,very simple

-

Operate:

-

automatic dispenser alcoholic gel

-

Filling volume:

-

5ml-5000ml

-

Function:

-

glass plastic bottle sealing and filling machine

For faster respond and recommend the most suitable machine for you, Please leave your detailed demands:

1. Send us a picture to show your bottle sample

2. Your filling material

3. The filling capacity of each bottle you need.

4. Your production speed requirement.

We can customize the suitable one for you according to your requirement.

Why Choose Us

1.15+ years factory

2. Professional R&D Team

3.customization service

4.100% QC inspection before shipment

6.Certificate By CE & SGS

7.No third party, from the factory and the buyer to sell one to one

8.Good after-sales experience, provide videos of installation, online support and engineer overseas services.

9. At least one year warranty

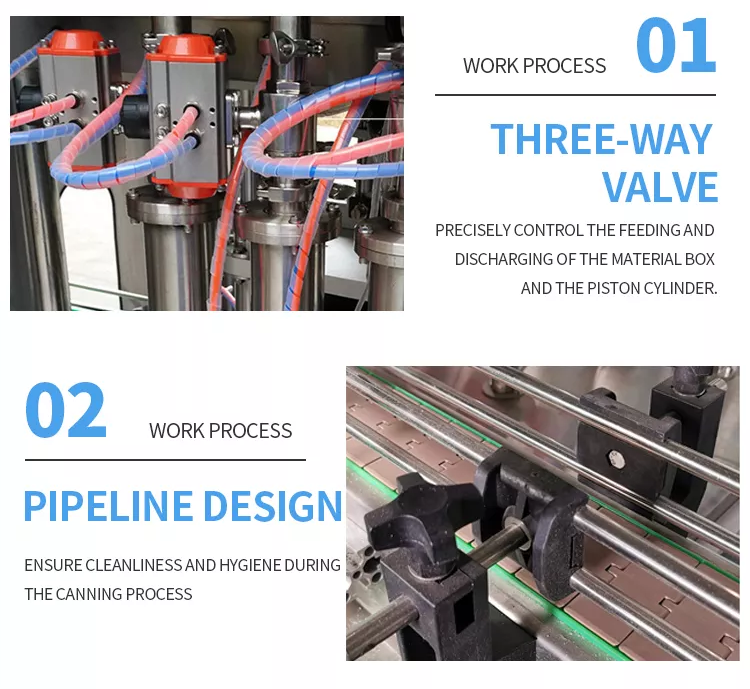

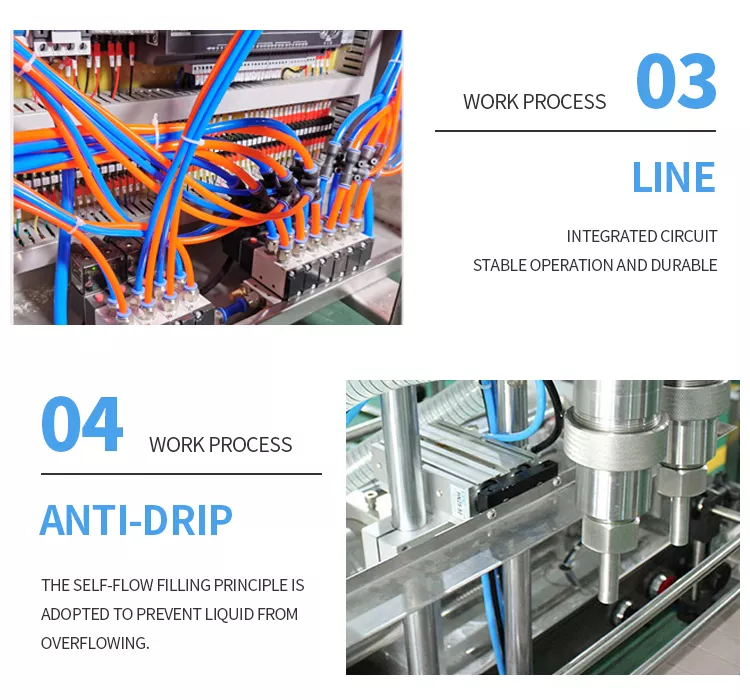

Product Description

Introduction

The fully automatic filling and capping machine is liquid filling line which is designed to fill bottles and jars with products of various viscosity, range from water thin liquids to thick creams. Widely used in cosmetic, food, oil and specialty industries. These inline piston filling machines can be option with different fill heads for meet different production capacity,variable speed drive conveyor, adjustable stainless steel frame, easy to operate PLC control panel.

Features

1, 304 Stainless steel heavy duty stainless steel welded C frame.

2, All parts contact with material is SUS316, sanitary, Teflon, Viton and hoses per your requirements.

3, Real time adjustability.

4, No bottle no fill, PLC control

5, Accurate filling volume, within ±1% and a total bottle counter.

6, Easy to maintain, no special tools are required.

7, Special seals or hoses by order.

8, Blocked nozzles for products that tend to string and drip.

9, Diving nozzles for bottom up filling of foaming products.

10, Bottle mouth localizer.

11, The filling head can also be added to suit your special need.

Application

KAPACK Automatic Liquids Bottle Filling Capping Labeling And Sealing Machine is suitable for filling all kinds of liquid and paste, such as tomato sauce, peanut sauce, cream, alcohol, fuel, glue, gasoline, kerosene, ethanol, methanol, benzene etc.

Specification

Attention:

1.All prices and parameters shown below are automatically generated by the system, if you want to know the exact information, please click "Contact Supplier" to send mail to us.

2. Because of the time difference, we suggest that you can choose to send us an inquiry instead of online chat.

3.When sending us an inquiry or message, please tell us your Email/ WhatsApp/Wechat etc. then our sales manager can contact you quickly.

|

item

|

value

|

|

Filling volume

|

100-5000 ml (Can be customized according to your requirements)

|

|

Filling speed

|

2000-2200b/h for 500ml

|

|

Filling precision

|

1ml

|

|

Filling head

|

2/4/6/8/10(Can be customized according to your requirements)

|

|

Bottle size

|

40-100mm(diameter); 80-300mm (height)

|

|

Air pressure

|

0.6-0.8Mpa

|

|

Weight

|

700kg

|

|

Voltage

|

220V/110V; 50hz/60hz

|

|

Size

|

2440*1480*2610mm

|

Details

If You Want To Know More About The Machine Details,

Please Send An Inquiry To Get It

Packing & Delivery

All the products before delivery should be tested by assemble and debugging engineer, wiped up and cleaned, the wrapped by stretch film to protect it from moist. The precision part needs flexible package. In addition, without standard tools, manual and other documents, and allow ex-factory confirmation sheet, the machine cannot leave factory. All the products will be packed in wooden case. The exported products use plywood case to pack. The foot margin of equipment fixed tightly to make the machine can experience loading and uploading, the upward mark will be posted on the wooden case.

Hot Searches