- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Xinke

-

Model Number:

-

XKFD330

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

10500x3700x1900mm

-

Weight:

-

8000 KG

-

production capacity:

-

30-200pcs/min.

-

experience:

-

more than 20 years of experience

-

Model:

-

XKFD330

-

Type:

-

kraft shopping bag making machine

-

Max raw material diameter:

-

1200mm

-

voltage:

-

380v

-

Paper thickness:

-

60-160gsm

-

After Warranty Service:

-

Video technical support

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Shopping bag

-

Material:

-

Paper

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Xinke

-

Model Number:

-

XKFD330

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

10500x3700x1900mm

-

Weight:

-

8000 KG

-

production capacity:

-

30-200pcs/min.

-

experience:

-

more than 20 years of experience

-

Model:

-

XKFD330

-

Type:

-

kraft shopping bag making machine

-

Max raw material diameter:

-

1200mm

-

voltage:

-

380v

-

Paper thickness:

-

60-160gsm

-

After Warranty Service:

-

Video technical support

Product Description

|

Model

|

XKFD-180

|

XKFD-220

|

XKFD-280

|

XKFD-330

|

XKFD-450

|

|

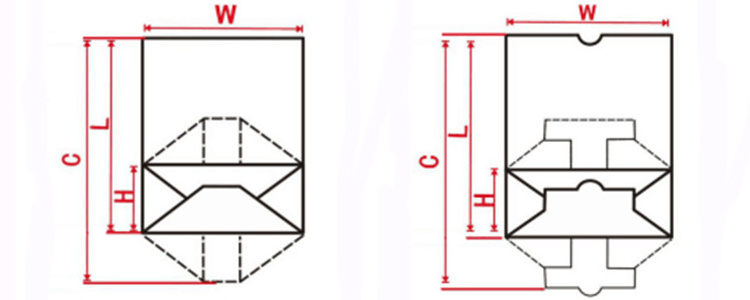

Width of Bag(mm)

|

80-180

|

80-220

|

100-280

|

150-330

|

220-450

|

|

Length of Bag(mm)

|

150-320

|

145-320

|

225-450

|

220-450

|

210-450

|

|

Width of Bag Bottom

|

50-105

|

60-120

|

60-160

|

60-160

|

80-180

|

|

Paper Grams(g/m2)

|

50-130

|

50-130

|

60-160

|

60-160

|

80-160

|

|

Inside Diameter Of Paper Core(mm)

|

76

|

76

|

76

|

76

|

76

|

|

Maximum Discharge Diameter(mm)

|

ɸ1200

|

ɸ1200

|

ɸ1200

|

ɸ1200

|

ɸ1200

|

|

Max Speed(pcs/min)

|

200

|

200

|

180

|

160

|

150

|

|

Total Power(kw)

|

10

|

10

|

12

|

12

|

15

|

|

Machine Weight (kg)

|

5000

|

5500

|

7000

|

8000

|

9000

|

|

Machine Size(mm)

|

9000*3000*1800

|

9000*3500*1800

|

10500*3600*1900

|

10500*3700*1900

|

10500*3800*1900

|

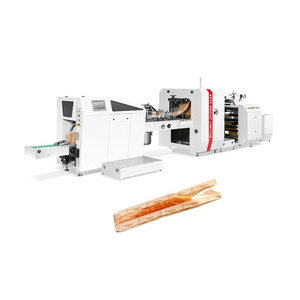

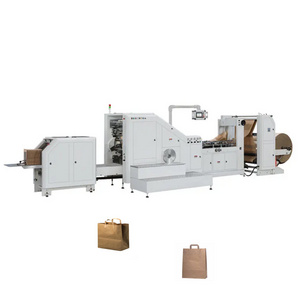

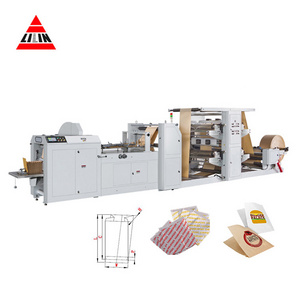

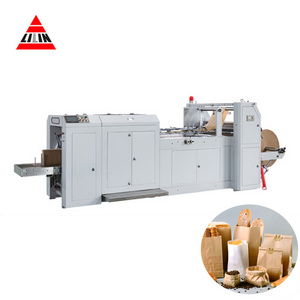

PRODUCT INTRODUCTION:

This machine can use the rolling paper, which is made of primary color paper or printed to produce square bottom paper bag to one time. This machine can produce various of paper bags, with fast speed, high production efficiency, is an ideal equipment for paper bag production.

This machine is composed of rolling paper feed (hydraulic feeding, automatic deviation correction, constant tension), side glue, printing paper electric eye tracking, original paper into roll, fixed length traction cutting, bag bottom indentation opening bottom, bag bottom gluing folding forming and bag output. The whole machine is controlled by the computer central control system, the touch screen display, and the servo motor controls the length of the paper bag.

According to customer needs, two/ four-color printing machine, Paper bag windowing device and paper bag hand holing device or paper handle bar device can be customized.

Production Process

You can tell me what you think,

and I will match a set of the most suitable production line for you.

After-sales service

1.Quality Commitment: one year guarranty,Lifelong maintenance, Vulnerable parts are

provided free of charge within 12 months.

2. After-sales Service: 24hours online to help customer solve problem.

3. Operation Guide: after the customer receives the goods, the engineer will guide the installation throughout.

4. Machine Parts: all machine parts are imported from famous imported brands , which are convenient for customers to repair and buy by themselves.

2. After-sales Service: 24hours online to help customer solve problem.

3. Operation Guide: after the customer receives the goods, the engineer will guide the installation throughout.

4. Machine Parts: all machine parts are imported from famous imported brands , which are convenient for customers to repair and buy by themselves.

We have a complete after-sales service team!

Hot Searches