- Product Details

- {{item.text}}

Quick Details

-

Heating Power (kW):

-

35 kW

-

Place of Origin:

-

China

-

Voltage:

-

Customrized

-

Weight (T):

-

3 T

-

Certification:

-

CE Certificate

-

Product name:

-

injection molding machine

-

Material:

-

SUS304/316

-

Feature:

-

Efficient

-

Keyword:

-

Plastic machine

-

Motor:

-

Servo Energy Saving

-

Function:

-

Plastic Parts Production

-

Name:

-

China thermoforming Machine

-

BRAND:

-

Proman

-

Color:

-

Customrized

-

Marketing Type:

-

New Product 2020

Quick Details

-

Max.Forming Height(mm):

-

150 mm

-

Forming Width (mm):

-

750 mm

-

Forming Length (mm):

-

750 mm

-

Heating Power (kW):

-

35 kW

-

Place of Origin:

-

China

-

Voltage:

-

Customrized

-

Weight (T):

-

3 T

-

Certification:

-

CE Certificate

-

Product name:

-

injection molding machine

-

Material:

-

SUS304/316

-

Feature:

-

Efficient

-

Keyword:

-

Plastic machine

-

Motor:

-

Servo Energy Saving

-

Function:

-

Plastic Parts Production

-

Name:

-

China thermoforming Machine

-

BRAND:

-

Proman

-

Color:

-

Customrized

-

Marketing Type:

-

New Product 2020

Product Description

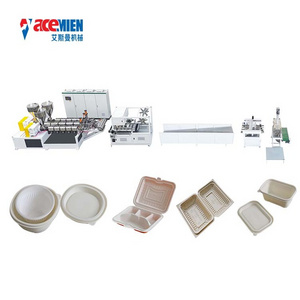

Disposable Clear Plastic Food Container Tray Box PET PP Thermoforming Making Machine

PM-7185 thermoforming machine is a new type of machine developed by our company according to the market and customer's demand. The machine is a kind of multi-station automatic machine, which has the synchronous complete forming, punching, and cutting, so easy to get the end plastic products. Therefore, the input of labor and the cost of production is greatly reduced, and the work efficiency is much more improved. It can be applied to metal, food, medicine, cosmetics and other PS/PET/PVC plastic products.

| PM-7185 | ||

| 1 | Suitable Material | PP, PS, PET, PVC, PLA, etc. |

| 2 | Material Width | 4 5 0-7 5 0mm |

| 3 | Thickness of Material | 0.15- 2.2 mm |

| 4 | Max. Forming Area | 710× 52 0mm |

| 5 | Min. Forming Area | 420×300mm |

| 6 | Forming Depth | 1 5 0mm |

| 7 | Max. Cutting Force | 6 0T (Used with heatable die system) |

| 8 | Maximum opening and closing stroke of forming mold | 300mm |

| 9 | Maximum opening and closing stroke of cutting die | 160mm |

| 10 | Positive molding product height | 13 0mm |

| 11 | Negative molding product height | 1 3 0mm |

| 12 | Stacking mechanism stroke | ≤500mm |

| 13 | Installed Power | 100KW |

| 14 | Heating Power | Upper furnace 25 KW, lower furnace 25 kw |

| 15 | Actual Energy Consumption | About 20KW/H |

| 16 | Power Supply | AC 380V/50Hz (3+N+PE) |

| 17 | Max. Production Speed | ≤10 cycles/minute |

| 18 | Use Compressed Air Pressure | 0.6~0.8bar |

| 19 | Consumption of Compressed Air | About 2.5-3.5 m³/minute |

| 20 | Cooling Method | The mold is cooled by circulating water |

| 21 | Machine Weight | 8 , 0 00kg |

| 22 | Dimension (L*W*H) | 9 000 m m ×2 300 m m ×2 500 m m |

Features

Features:

1.Adopt PLC control, the whole system is fu

lly automatic, paramet

ers digital display, easy operation

2.This machine

co

mbines

servo motor sheet feeding

,

vacuum forming system

,

servo motor + gas-liquid pressure cylinder

(cutting pressure:

60

T)

, stackin

g, counting and finished products conveying into one machine

3.4-pillar hydrauli

c structure, sta

ble quality and low noise

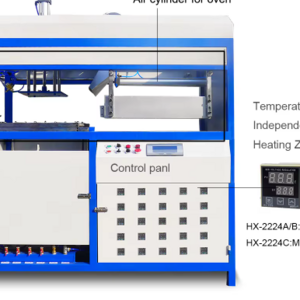

4.Imported ceramic heater, double heating oven, accurate temperature control, long life

5.We provide customized service for you, the machine forming area can be designed and

manufactured as your need.

6.Advanced servo motor sheet transporting system, formi

ng length can be adjusted.

|

Machine framework, Adopting national standard square steel pipe, the surface is painted with three layers, the frame is strong and durable, not easy to rust |

| Sheet delivering chain track |

|

|

|

Adjstable forming table, maximum forming area is 710*850mm. Mold table inside through with cooling water to low the mold temperature. This is the guarantee to ensure the production speed. |

|

Powerful and stable cutting station. Full servo motor drive which makes machine production speed faster. |

|

Hot Searches