- Product Details

- {{item.text}}

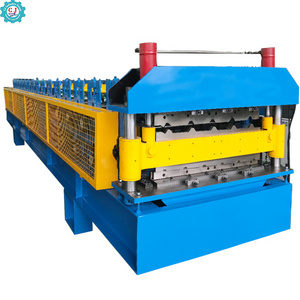

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

XN

-

Voltage:

-

380v 50Hz

-

Dimension(L*W*H):

-

45*5*8m

-

Weight:

-

12000 kg

-

Product name:

-

profile machine

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Roller material:

-

45#steel Chrome Plated

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Main frame:

-

350H Steel

-

Keywords:

-

Colored Steel Roof Making Machine

-

Application:

-

Industiral Building

-

Control system:

-

PLC(imported Brand)

-

Advantage:

-

Fast Speed

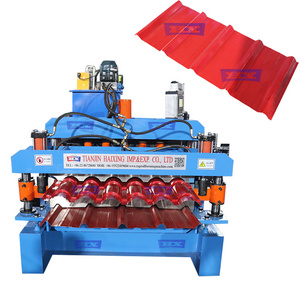

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Glaze

-

Production Capacity:

-

2-45m

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

XN

-

Voltage:

-

380v 50Hz

-

Dimension(L*W*H):

-

45*5*8m

-

Weight:

-

12000 kg

-

Product name:

-

profile machine

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Roller material:

-

45#steel Chrome Plated

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Main frame:

-

350H Steel

-

Keywords:

-

Colored Steel Roof Making Machine

-

Application:

-

Industiral Building

-

Control system:

-

PLC(imported Brand)

-

Advantage:

-

Fast Speed

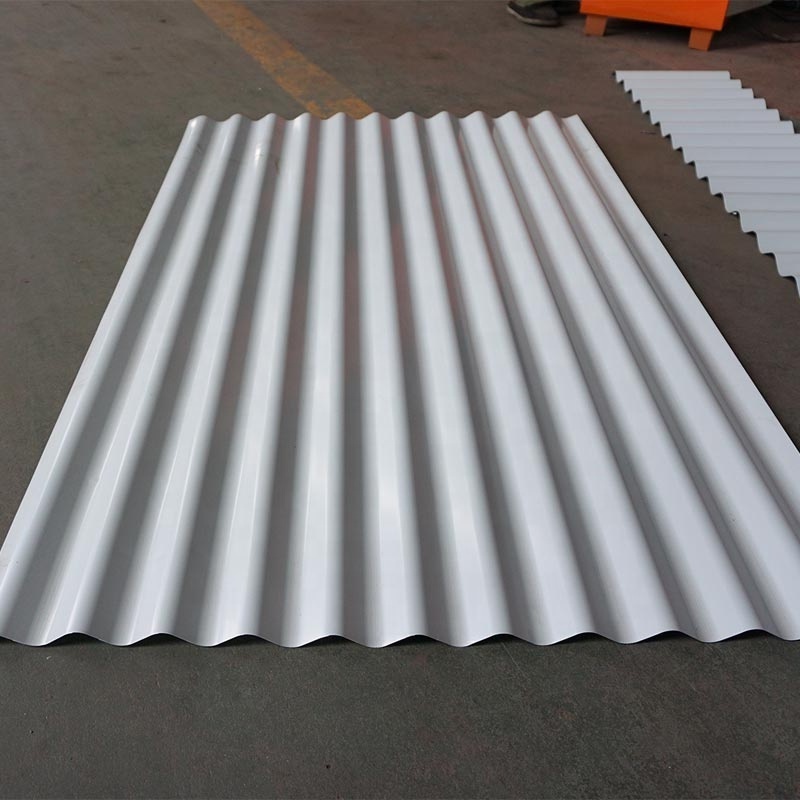

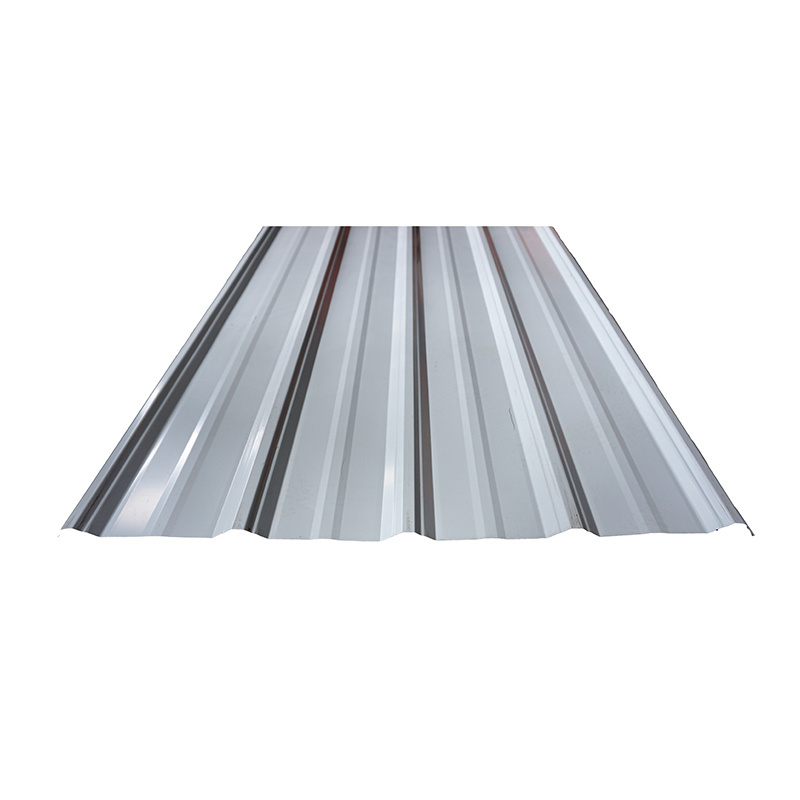

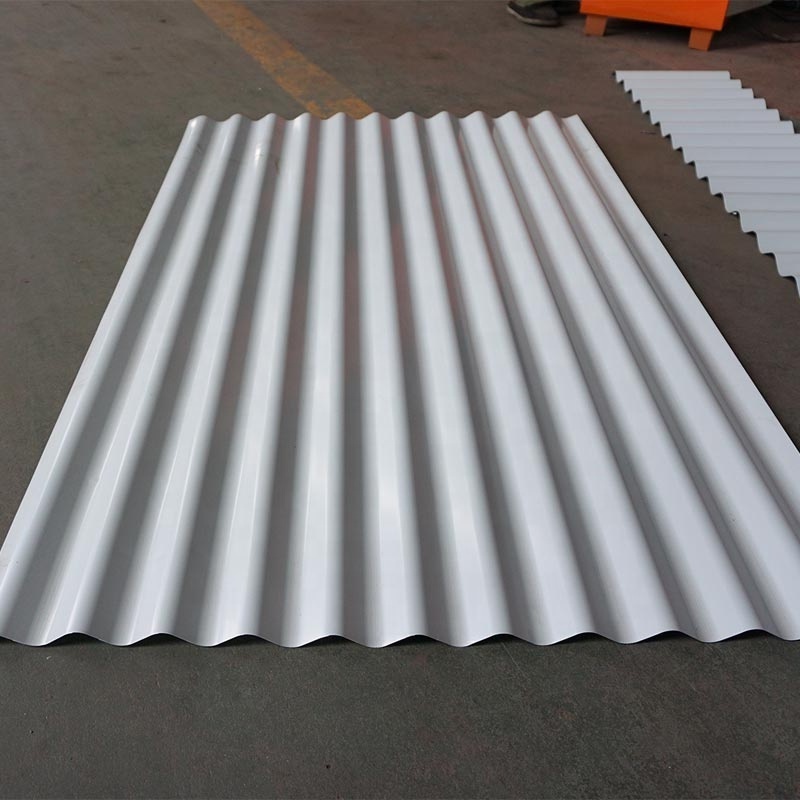

Application

Sample

product description

Other machines

We can produce too many types roofing panels roll forming machine ,especially according to your request to produce.you need provide panel drawing,feeding width,effective width,and materials thickness,then we can send you more machine details.please feel free contact me.

Specification

|

control system :

|

|

automatic PLC frequency control

|

|

|

|||

|

roller steps :

|

|

11/16 rows or as your need

|

|

|

|||

|

main power :

|

|

4 kw

|

|

|

|||

|

fax speed :

|

|

8-12 m/min

|

|

|

|||

|

feeding width :

|

|

1000 mm or as your need

|

|

|

|||

|

thickness of the plant :

|

|

0.3-0.8 mm

|

|

|

|||

|

feeding material :

|

|

color steel

|

|

|

|||

|

roller's material :

|

|

45#steel with chrome treatment on surface

|

|

|

|||

|

voltage :

|

|

380 V,50 Hz,3 Phase

|

|

|

|||

|

roller's material :

|

|

45#steel with chrome treatment on surface

|

|

|

|||

|

Cutting blade material:

|

|

Cr 12 Mov

|

|

|

|||

|

Shaft material:

|

|

45# Steel Outer Diameter: 70 mm

|

|

|

|||

|

Roller material:

|

|

45#steel

|

|

|

|||

|

Raw material:

|

|

Color Steel Coil

|

|

|

|||

|

Color :

|

|

Blue or as your need

|

|

|

|||

Cutting Mechanism

It adopts hydraulic motor drive and automatic location to decide the dimension and cut the target products.

Roller system

Material of the roller:High grade No.45 forged steel.Roller station: 16 rows or custom as customer's requirements.

Thickness of feeding material:0.3-0.8 mm.

Thickness of feeding material:0.3-0.8 mm.

Computer Control Cabinet

It adopts Delta PLC to control.The target piece length is adjustable and digit of it can be adjusted.Computed mode has two modes automatic and manual one.

Hydraulic System

Match equipment hydraulic motor,a set of hydraulic tank,a set of hydraulic oil pump,two hydraulic pipes and two sets of electromagnetism valves.

Power:5.5kw

Power:5.5kw

Manual Uncoiler

Maximal out diameter: 1250mmCoil placement in the coil holder:hydraulic hoist

Working speed:0- 15m/min adjustable

Main motor power:5 5KW AC motor

Working speed:0- 15m/min adjustable

Main motor power:5 5KW AC motor

Receiving Table

Maximal out diameter: 1250mmCoil placement in the coil holder:hydraulic hoist.

packaging and shipping

Our Advantages

Large gantry milling machine

Our factory uses a 13-meter large gantry milling machine. This equipment is used to process the main frame of the machine, so that the large frame has a higher flatness and better levelness, and the accuracy can reach 0.05 mm. Effectively ensure product stability.

Spray paint workshop

Using environmentally friendly resin paint, two-coating and two-spray new technology, the paint surface has good adhesion, durability, corrosion resistance, aging resistance and no fading.

Shot blasting machine

The use of large-scale shot blasting with six heads for rust removal and the deep treatment of the overall frame improves the intrinsic quality of the paint film and steel and prolongs its service life.

Electrical control

The electrical control systems of the machines in our factory are all programmed and designed by our factory engineers.If there is a problem with the operation of the travel electrical appliance,the electrical engineer can assist the customer through video to ensure that the problem is solved in time.

Machining

Our factory has purchased more than 50 processing machine, including CNC machining centers, CNC lathes, grinding machines, milling machines , sawing machines, drilling machines, etc.,to ensure that each component is processed by itself, and undergoes strict quality inspection to ensure product quality.

Data milling machine

All the hole positions of the vertical plate of the computer C-shaped steel equipment ,which is a hot-selling product of our

factory ,are processed by this equipment ,and the hole positions are accurate . The vertical plates of all C-section steel equipment are interchangeable for after-sales convenience.

factory ,are processed by this equipment ,and the hole positions are accurate . The vertical plates of all C-section steel equipment are interchangeable for after-sales convenience.

Hot Searches