- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v/380v -Customized

-

Power:

-

5.5-74 kw -Customized

-

Dimension(L*W*H):

-

1200*10000 mm, 1380*1000*1800mm - Customized,

-

Weight (KG):

-

1000

-

Drying capacity:

-

6-8t/h

-

Dryig process:

-

Continuous Automatic Drying

-

Moisture of end products:

-

<5%

-

Evaporation Capacity(kg/h):

-

Customized

-

Raw material:

-

Multiple Material

-

Heating source:

-

Coal, biomass pellets, natural gas, liquefied gas

-

Drying Oven Application:

-

Industrial Dryer Machine

-

Brand:

-

Hengchang

Quick Details

-

Type:

-

Drum Drying Equipment

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Henchang

-

Voltage:

-

220v/380v -Customized

-

Power:

-

5.5-74 kw -Customized

-

Dimension(L*W*H):

-

1200*10000 mm, 1380*1000*1800mm - Customized,

-

Weight (KG):

-

1000

-

Drying capacity:

-

6-8t/h

-

Dryig process:

-

Continuous Automatic Drying

-

Moisture of end products:

-

<5%

-

Evaporation Capacity(kg/h):

-

Customized

-

Raw material:

-

Multiple Material

-

Heating source:

-

Coal, biomass pellets, natural gas, liquefied gas

-

Drying Oven Application:

-

Industrial Dryer Machine

-

Brand:

-

Hengchang

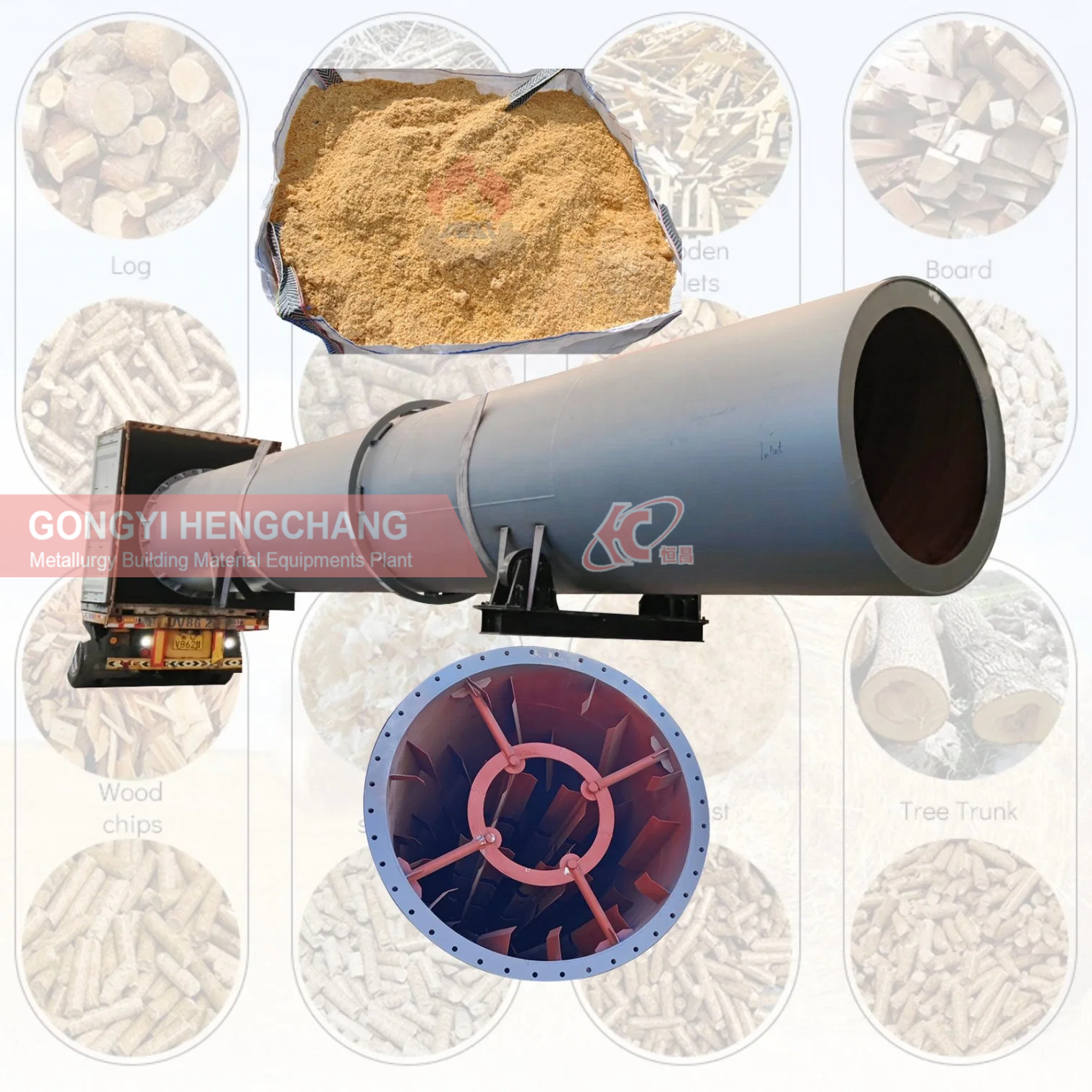

Products Description

Rotary dryer is widely used for

drying slag limestone, coal powder, slag, clay, etc.

Dryer can

also be used in building materials,metallurgy, chemical and cement industry.

Rotary Dryer mainly consists of dryer body, raw material feeding plate, driving and supporting device, seal ring, etc.

Dryer can be generally divided into four types, they are: rotary dryer, triple-drum dryer,

indirect heat transfer dryer, vertical dryer.

indirect heat transfer dryer, vertical dryer.

Different kind of dryer has its own characters and advantages, the specific choice of a special dryer depends on different elements.

|

Specifications(mm)

|

Tilt(%)

|

Rotate speed(r/min)

|

The max. intake air temperature(°C)

|

Power(kw)

|

Capacity(t/h)

|

Weight(kg)

|

|

600x6000

|

3-5

|

3-8

|

≤700

|

3

|

0.5-1.5

|

2.9

|

|

800x8000

|

3-5

|

3-8

|

≤700

|

4

|

0.8-2.0

|

3.5

|

|

800x10000

|

3-5

|

3-8

|

≤700

|

4

|

0.8-2.5

|

4.5

|

|

1000x10000

|

3-5

|

3-8

|

≤700

|

5.5

|

1.0-3.5

|

5.6

|

|

1200x10000

|

3-5

|

3-8

|

≤700

|

7.5

|

1.8-5

|

14.5

|

|

1200x12000

|

3-5

|

3-8

|

≤700

|

11

|

2-6

|

14.8

|

|

1500x12000

|

3-5

|

2-6

|

≤800

|

15

|

3.5-9

|

17.8

|

|

1800x12000

|

3-5

|

2-6

|

≤800

|

18

|

5-12

|

25

|

|

2200x12000

|

3-5

|

1.5-6

|

≤800

|

18.5

|

6-15

|

33

|

|

2200x18000

|

3-5

|

1.5-6

|

≤800

|

22

|

10-18

|

53.8

|

|

2200x20000

|

3-5

|

1.5-6

|

≤800

|

30

|

12-20

|

56

|

|

2400x20000

|

3-5

|

1.5-5

|

≤800

|

37

|

18-30

|

60

|

|

3000x20000

|

3-5

|

1.5-5

|

≤800

|

55

|

25-35

|

78

|

|

3000x25000

|

3-5

|

1.5-5

|

≤800

|

75

|

32-40

|

104.9

|

Application Field

Hengchang Rotary Dryer is widely used in the field of build materials,metallurgies,chemical industry, cement and so on.

(1)Our dryers can dry slag, coal powder, mining powder, clay, sand, limestone,chicken manure,sludge,slurry,sawdust and so on.

(2)Powder & particle:

Sands, limestone, stones, clay, mineral filter cake, coal, iron sulphate, filter cakes, fly ash, gypsum etc.

(3)

Damp and sticky material:

Coal slime, sewage sludge, bentonite, Kaolin etc.

(4)

Corrosive material:

Distillers ‘grains, Fertilizer, animal dung, slag etc.

(5)

Biomass material:

Sawdust, wood chips etc.

Drying Effect

Biomass dryer is an environmentally friendly drying equipment!

1.The processing output is high, the biomass slime dryer can process a large amount of coal materials every day, it can be produced continuously, and the work efficiency is high.

2.The drying effect is good and the drying degree is uniform. The material dried by the biomass dryer has a good color and a uniform drying degree.

Product Features

According to your raw materials, we also provide three-layer rotary drum dryer, three-layer rotary drum dryer which can improve the internal structure of the original single drum dryer, increase the pre-drying of wet materials before entering the machine and prolong the drying time of wet materials in the machine, Coupled with sealing, heat preservation and reasonable supporting measures, the production capacity of the dryer is increased by 48-80% compared with the original single cylinder dryer, the evaporation intensity per unit volume can reach 120-180kg/m3, and the standard coal consumption is only 6-8kg/t. Moreover, it effectively reduces the occupied area, and the smaller volume is convenient for sea transportation.

Temperature measurement sensors and digital display instruments are installed at the high and low-temperature pipelines of the drying system to achieve the best drying effect and ensure the safe operation of the system.

It can be equipped with a mechanical chain coal-fired hot blast stove, which has strong adaptability to coal types, and the overall thermal efficiency can reach more than 80%. The average coal consumption per ton of precipitation is not more than 176kg of standard coal.

This machine also have gas cleaning system. With cyclone, air fan, wet dust filter. Without pollution.

The drum body adopts screw + plate structure, double-layer plate and turnover plate are continuously turned up and down to makethe material fully touch with the hot air, promote the heat exchange, ensure the drying efficiency.

Hot Searches