- Product Details

- {{item.text}}

Quick Details

-

Power:

-

0.55kw-72kw

-

Dimension(L*W*H):

-

customized

-

Weight:

-

KG

-

Product name:

-

vacuum evaporator concentrator

-

Material:

-

SS304 SS316L

-

volume:

-

50L-50000L

-

vaccum pump:

-

1.5KW-11KW

-

heating way:

-

steam or electric

-

application:

-

juice food oil

-

Name:

-

Short-range Molecular Distillation System

-

Application Industries:

-

Food

-

Main uses:

-

falling film vacuum pressure ball spherical

-

Origin:

-

China, Wenzhou, LENO

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LENO

-

Voltage:

-

120V-480V

-

Power:

-

0.55kw-72kw

-

Dimension(L*W*H):

-

customized

-

Weight:

-

KG

-

Product name:

-

vacuum evaporator concentrator

-

Material:

-

SS304 SS316L

-

volume:

-

50L-50000L

-

vaccum pump:

-

1.5KW-11KW

-

heating way:

-

steam or electric

-

application:

-

juice food oil

-

Name:

-

Short-range Molecular Distillation System

-

Application Industries:

-

Food

-

Main uses:

-

falling film vacuum pressure ball spherical

-

Origin:

-

China, Wenzhou, LENO

Products Description

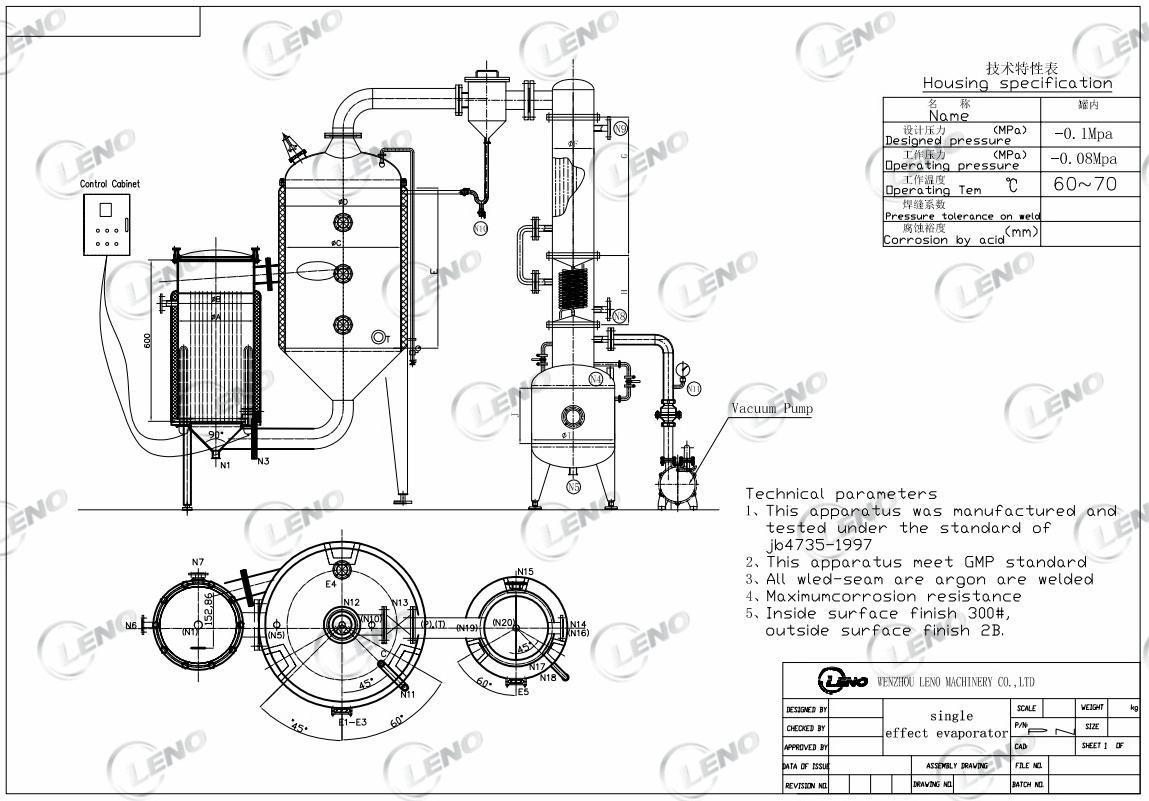

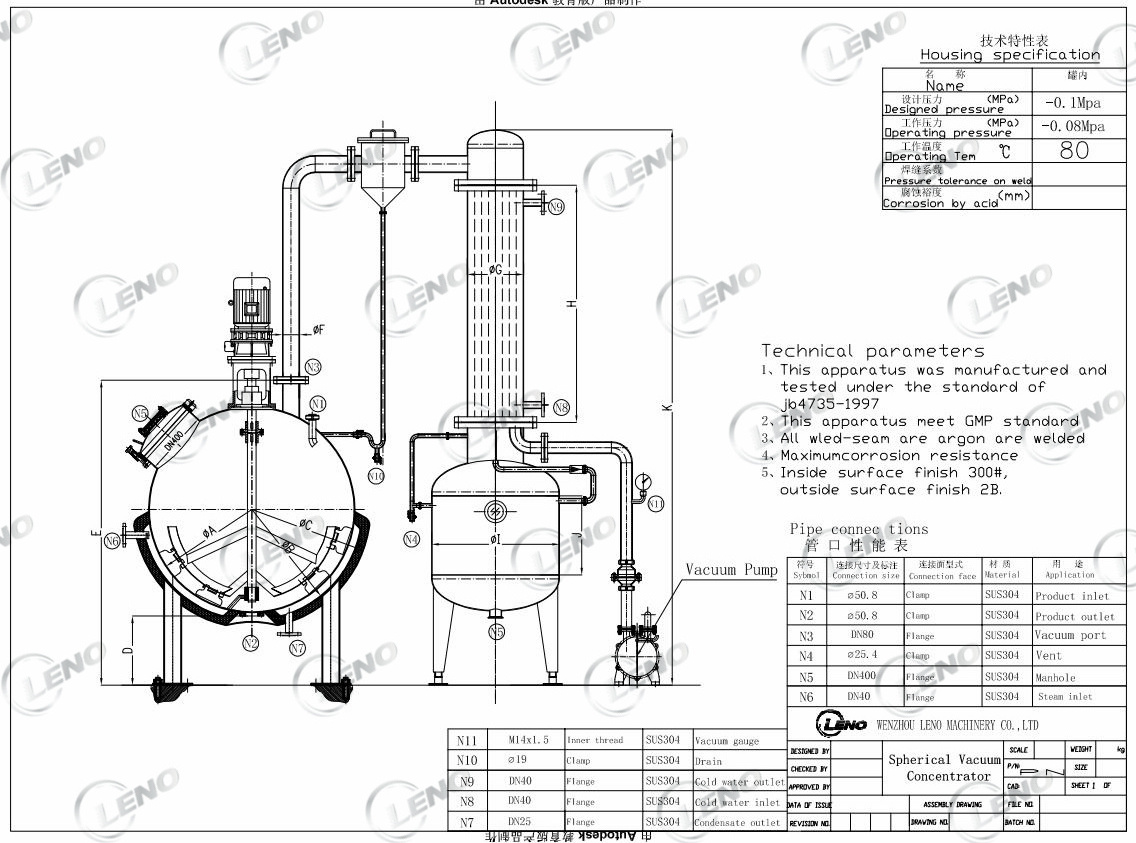

How it works:

The steam enters the shell process of the heating chamber. After the material liquid in the column tube is heated,

the liquid level rises. It is sprayed into the evaporation chamber from the nozzle for vapor-liquid separation. The material

liquid returns from the circulating tube to the lower part of the heating chamber for reheating. When the material liquid is

heated and sprays into the evaporation chamber to form a cycle. The degree of concentration of the liquid shall be discharged from the outlet after sampling. The secondary steam evaporated from the evaporation chamber eliminates the foam through the foam remover and then passes through the vapor-liquid separator. Some of the material and liquids return to the evaporation chamber. The remaining secondary steam is cooled into liquid by the condenser and cooler and enters the collector. The non-coagulated gas is extracted by the vacuum pump.

the liquid level rises. It is sprayed into the evaporation chamber from the nozzle for vapor-liquid separation. The material

liquid returns from the circulating tube to the lower part of the heating chamber for reheating. When the material liquid is

heated and sprays into the evaporation chamber to form a cycle. The degree of concentration of the liquid shall be discharged from the outlet after sampling. The secondary steam evaporated from the evaporation chamber eliminates the foam through the foam remover and then passes through the vapor-liquid separator. Some of the material and liquids return to the evaporation chamber. The remaining secondary steam is cooled into liquid by the condenser and cooler and enters the collector. The non-coagulated gas is extracted by the vacuum pump.

|

Profile type

|

vacuum evaporator concentrator

|

|

|

||

|

Material

|

SS304 or SS316L

|

|

|

||

|

Capacity

|

0.1T/H-5T/H (Customized)

|

|

|

||

|

Heater type

|

Electric heating / Steam heating

|

|

|

||

|

The Working Temperature

|

40°C~80°C

|

|

|

||

|

The Working Pressure

|

-0.08Mpa

|

|

|

||

|

Power

|

0.55KW-30KW

|

|

|

||

|

|

|

|

|

||

|

PARTS DETAILS

|

1.Quick open manhole / Pressure manhole

|

|

|

||

|

|

2.Various types of CIP cleaners

|

|

|

||

|

|

3.Sterile respirator

|

|

|

||

|

|

4.Adjustable Legs

|

|

|

||

|

|

5.Inlet and Outlet sanitary valve.

|

|

|

||

|

|

6.Thermometer (According to customer requirements ).

|

|

|

||

|

|

7.Scraped wall mixer .(According to customer requirements).

|

|

|

||

|

|

8.Liquid level meter and lever controller (According to customer requirements) .

|

|

|

||

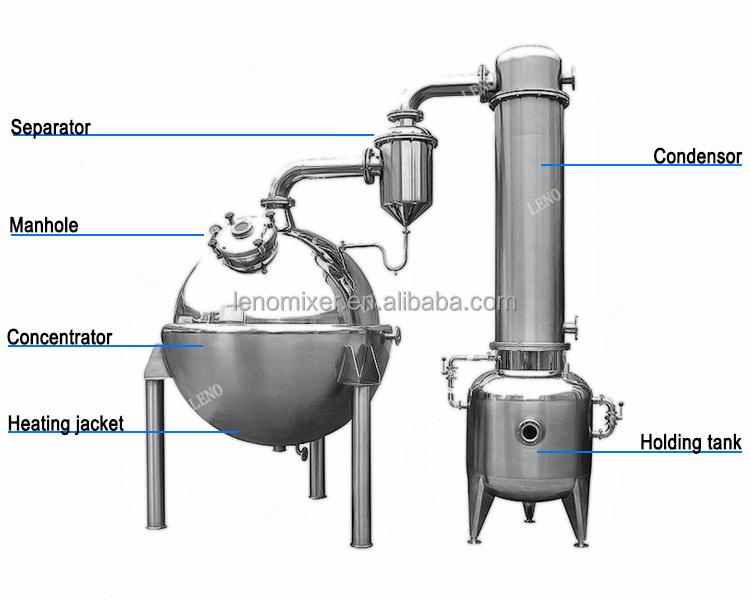

1. vacuum concentrator makes use of the methods of vacuum evaporation or mechanical separation to concentrate the

materials.vacuum concentrator is composed of heater, evaporation chamber, foam remover, condenser, cooler and liquid receiver, etc. All the parts contacting with materials are made of SUS304/316L.

2. vacuum concentrator is suitable for the liquid evaporation concentration in the industries of pharmacy, food, chemical, light industry, etc. This equipment features short concentration time, fast evaporation time and can protect the thermal sensitivity materials well.

3. At present, in order to improve the concentrated products’ quality, concentrator widely adopts vacuum concentration

process. Usually, under 18-8Kpa low pressure state, it heats up the liquid materials by indirect steam heating to make it

evaporate under low-temperature. So, the temperature difference between heating steam and liquid materials is larger. Under the same heat transfer condition, its evaporation rate is higher than atmospheric evaporation, which can reduce the liquid nutrition loss.

materials.vacuum concentrator is composed of heater, evaporation chamber, foam remover, condenser, cooler and liquid receiver, etc. All the parts contacting with materials are made of SUS304/316L.

2. vacuum concentrator is suitable for the liquid evaporation concentration in the industries of pharmacy, food, chemical, light industry, etc. This equipment features short concentration time, fast evaporation time and can protect the thermal sensitivity materials well.

3. At present, in order to improve the concentrated products’ quality, concentrator widely adopts vacuum concentration

process. Usually, under 18-8Kpa low pressure state, it heats up the liquid materials by indirect steam heating to make it

evaporate under low-temperature. So, the temperature difference between heating steam and liquid materials is larger. Under the same heat transfer condition, its evaporation rate is higher than atmospheric evaporation, which can reduce the liquid nutrition loss.

Product Paramenters

|

Model

|

(L)

Equipment volume |

(KG/H)

Evaporation quantity |

(Mpa)

Working Pressure in jacket |

(Mpa)

Vacuum degree in tank |

KW

Vacumm Pump |

(KG)

Weight of equipment |

(RPM)

Agitator speed |

|

|

|

|

|

|

|

|

|

|

RVC100

|

150

|

100

|

≤0.1MPa

(According to customer requirements) |

-0.08Mpa

|

1.5KW

|

320

|

(According to customer requirements)

|

|

RVC200

|

250

|

200

|

|

|

2.2KW

|

460

|

|

|

RVC500

|

600

|

500

|

|

|

3.0KW

|

680

|

|

|

RVC1000

|

1000

|

1000

|

|

|

4.0KW

|

860

|

|

|

RVC2000

|

2000

|

2000

|

|

|

5.5KW

|

1120

|

|

|

RVC3000

|

3000

|

3000

|

|

|

7.5KW

|

1300

|

|

|

RVC5000

|

5000

|

5000

|

|

|

11.0KW

|

1700

|

|

Product Images

Various kinds of the mixers showing

LENO magnetic agitator

is a type of mixing equipment that uses a magnetic field to rotate a magnetic stir bar inside a container. The stir bar is typically made of a magnetic material, such as PTFE -coated neodymium, and is placed inside the container along with the material being mixed.

LENO paddle mixer

is a type of mixing equipment used in various industries to blend dry powders, granules, and other solid materials. The mixer consists of a large, rotating agitator, called a paddle, that moves the material around inside the mixer. The paddles are typically shaped like wings or blades, and they move the material in a tumbling motion, creating a gentle yet effective blending action.

LENO anchor agitator is a type of mixing equipment used in various industrial applications to blend viscous liquids and pastes. The agitator consists of a central shaft with several blades, or anchors, attached to it. The anchors are typically flat, rectangular or trapezoidal in shape, and are positioned perpendicular to the shaft. As the shaft rotates, the anchors move the material around in a scraping motion, creating a mixing action that ensures thorough blending of the ingredients.

LENO scraped wall agitator is a type of mixing equipment used in various industrial applications to blend high viscosity materials, such as creams, gels, pastes, and ointments. The agitator consists of a central shaft with several blades, or scrapers, attached to it. The scrapers are typically rectangular or trapezoidal in shape, and are positioned parallel to the shaft. As the shaft rotates, the scrapers move along the wall of the mixing vessel, scraping off the material and ensuring that it is thoroughly mixed.

LENO high shear mixer is a type of mixing equipment used in various industrial applications to blend and emulsify

materials. The mixer consists of a rotor and stator assembly, which work together to create a high shear force that breaks down particles and blends the material into a uniform mixture.

LENO propeller agitator is a type of mixing equipment used in various industrial applications to blend low to medium viscosity liquids. The agitator consists of a central shaft with several blades, or propellers, attached to it. The propellers are typically flat, curved, or angled in shape, and are positioned perpendicular to the shaft. As the shaft rotates, the propellers create a flow pattern that circulates the material and blends it together.

LENO dispersing mixer is a type of mixing equipment used in various industrial applications to disperse, homogenize and

deagglomerate materials. The mixer consists of a rotor-stator assembly, which works together to create a high shear force that breaks down particles and blends the material into a uniform mixture.

LENO spiral mixer is a type of mixing equipment used in commercial bakeries and food processing industries for mixing dough. The mixer has a unique design that uses a spiral-shaped dough hook to mix the ingredients together.

LENO anchor agitator is a type of mixing equipment used in various industrial applications to blend viscous liquids and pastes. The agitator consists of a central shaft with several blades, or anchors, attached to it. The anchors are typically flat, rectangular or trapezoidal in shape, and are positioned perpendicular to the shaft. As the shaft rotates, the anchors move the material around in a scraping motion, creating a mixing action that ensures thorough blending of the ingredients.

LENO scraped wall agitator is a type of mixing equipment used in various industrial applications to blend high viscosity materials, such as creams, gels, pastes, and ointments. The agitator consists of a central shaft with several blades, or scrapers, attached to it. The scrapers are typically rectangular or trapezoidal in shape, and are positioned parallel to the shaft. As the shaft rotates, the scrapers move along the wall of the mixing vessel, scraping off the material and ensuring that it is thoroughly mixed.

LENO high shear mixer is a type of mixing equipment used in various industrial applications to blend and emulsify

materials. The mixer consists of a rotor and stator assembly, which work together to create a high shear force that breaks down particles and blends the material into a uniform mixture.

LENO propeller agitator is a type of mixing equipment used in various industrial applications to blend low to medium viscosity liquids. The agitator consists of a central shaft with several blades, or propellers, attached to it. The propellers are typically flat, curved, or angled in shape, and are positioned perpendicular to the shaft. As the shaft rotates, the propellers create a flow pattern that circulates the material and blends it together.

LENO dispersing mixer is a type of mixing equipment used in various industrial applications to disperse, homogenize and

deagglomerate materials. The mixer consists of a rotor-stator assembly, which works together to create a high shear force that breaks down particles and blends the material into a uniform mixture.

LENO spiral mixer is a type of mixing equipment used in commercial bakeries and food processing industries for mixing dough. The mixer has a unique design that uses a spiral-shaped dough hook to mix the ingredients together.

Hot Searches