- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

100 mm

-

Brand Name:

-

Rekeer

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

6800 KG

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

380V 220V Optional

-

Dimension(L*W*H):

-

4050*1800*2150mm

-

Modle:

-

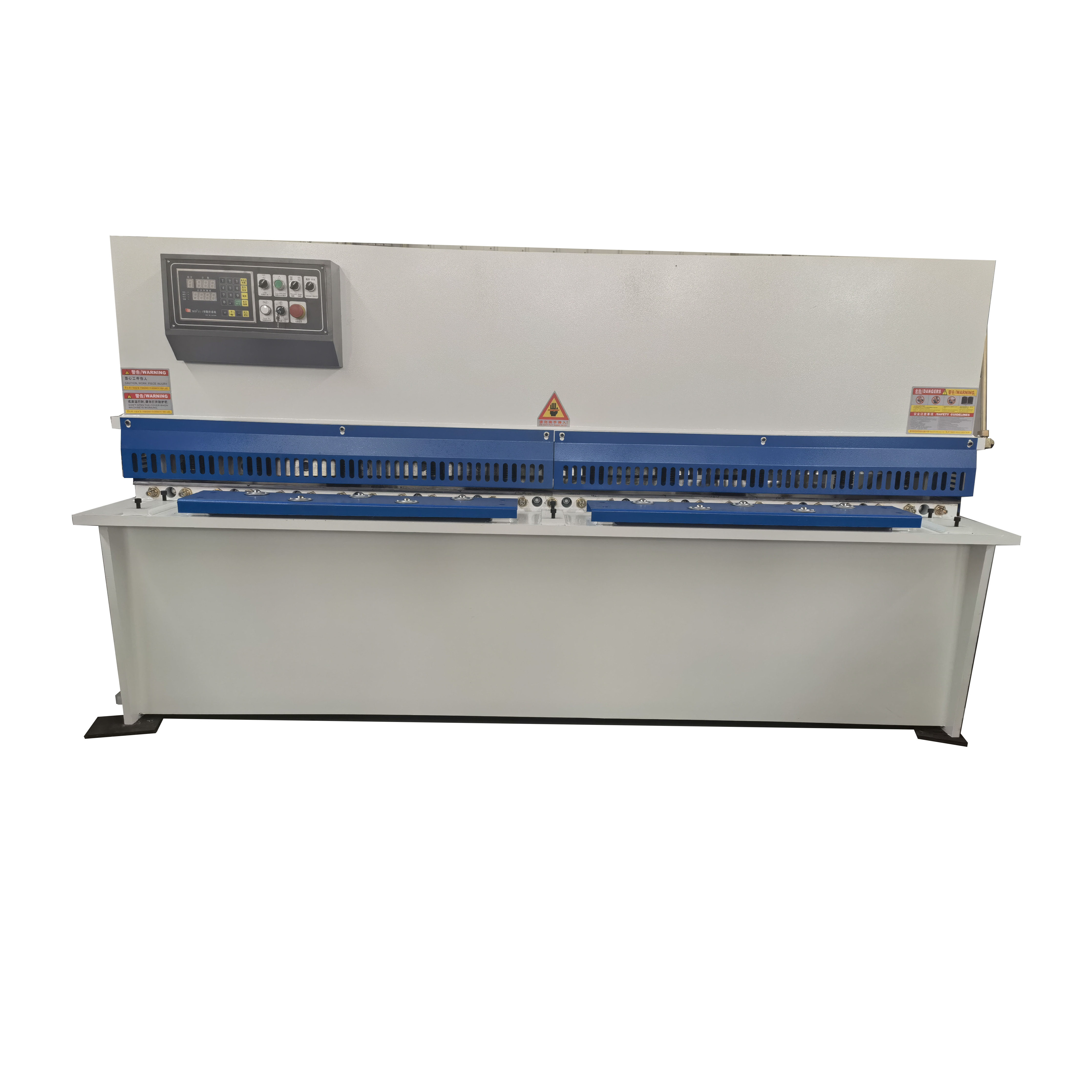

QC12Y-4X2500

Quick Details

-

Max. Cutting Width (mm):

-

3200

-

Max. Cutting Thickness (mm):

-

6 mm

-

Blade Length (mm):

-

2000 mm

-

Throat Depth (mm):

-

100 mm

-

Brand Name:

-

Rekeer

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

6800 KG

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

380V 220V Optional

-

Dimension(L*W*H):

-

4050*1800*2150mm

-

Modle:

-

QC12Y-4X2500

Product Paramenters

|

Model

|

Thuckness

|

Width

|

Cutting Angel

|

Material Intension

|

Backgange travei

|

Cutting Times

|

Power

|

Weight

|

Overall dimension

|

|

TYPE

|

(mm)

|

(mm)

|

(°)

|

(KN/CM)

|

(mm)

|

(T/min)

|

(kw)

|

(kg)

|

L*W*H(mm)

|

|

4*2500

|

4

|

2500

|

1°30′

|

≤450

|

20-600

|

16

|

5.5

|

3500

|

3300*1610*1620

|

|

4*3200

|

4

|

3200

|

1°30′

|

≤450

|

20-600

|

14

|

5.5

|

4500

|

3840*1610*1620

|

|

4*4000

|

4

|

4000

|

1°30′

|

≤450

|

20-600

|

10

|

5.5

|

6500

|

4600*1700*1700

|

|

6*2500

|

6

|

2500

|

1°30′

|

≤450

|

20-600

|

14

|

7.5

|

5000

|

3400*1610*1620

|

|

6*3200

|

6

|

3200

|

1°30′

|

≤450

|

20-600

|

12

|

7.5

|

6000

|

3840*1610*1620

|

|

6*4000

|

6

|

4000

|

1°30′

|

≤450

|

20-600

|

8

|

7.5

|

8200

|

4620*1750*1700

|

|

12*2500

|

12

|

2500

|

2°

|

≤450

|

20-600

|

9

|

18.5

|

9000

|

3500*2150*2000

|

Products Description

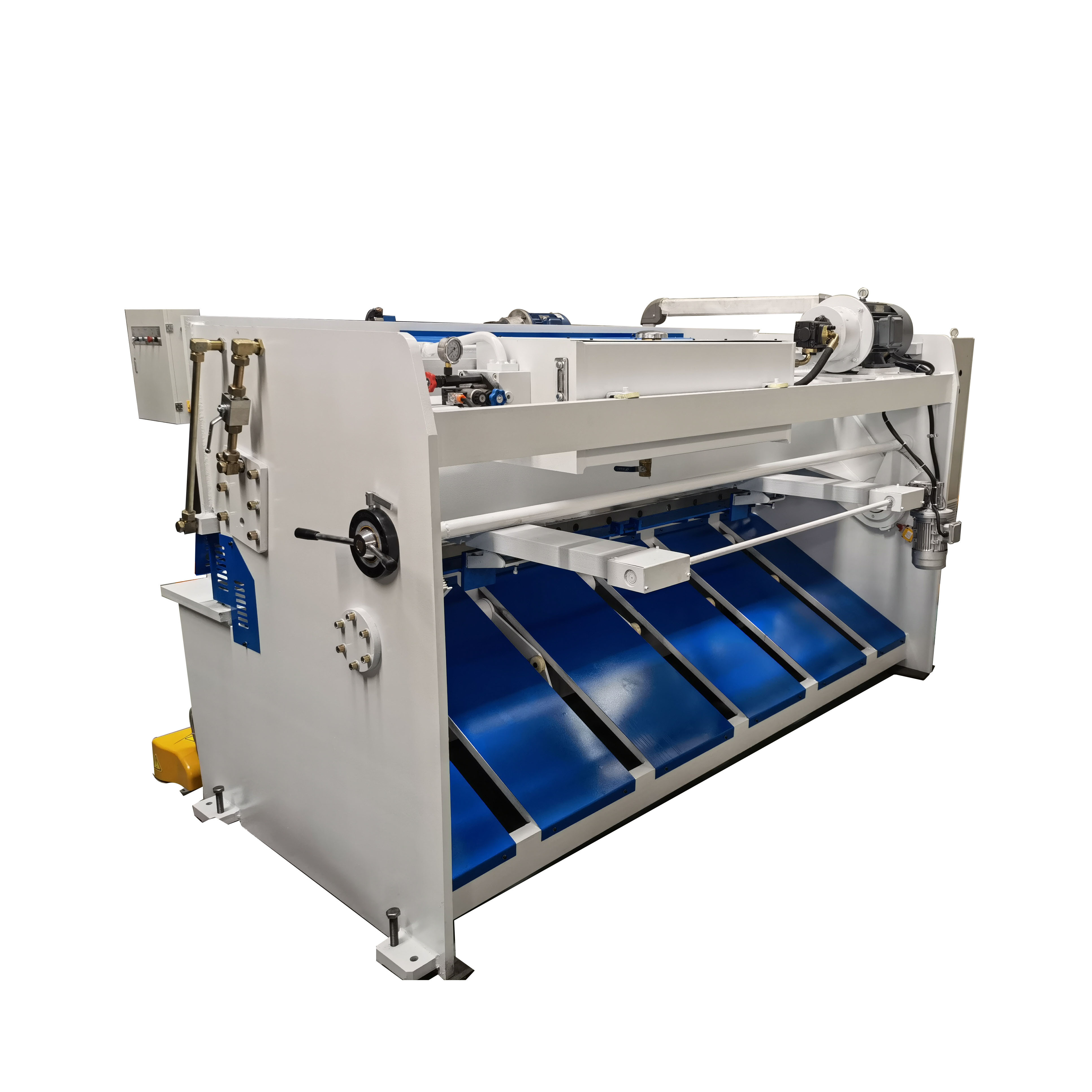

The host adopts the QC12Y series model, with the economical special numerical control system;

The post-block position is displayed in real time;

Multi-step programming function, after the automatic operation and continuous positioning of the material, the automatic accurate adjust- ment of the post-block position;

The shearing count function shows the shear number in real time

The rear block adopts the inlet ball screw to ensure the positioning accuracy of the rear retaining material, and the machining precision is higher.

1、Using rolling steel ballreduces frictionensure the workpiece surface is not scratched

2、Simple and quick manual adjustment,

the implementation of the blade gap adjustment.

3、Use brand motors, not only low noise, but also long service life.

4、

Recommend Products

Hot Searches