- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Upward Continuous Casting Copper Rod Making Machine

-

Application:

-

Making 8mm copper rod

-

Usage:

-

Castintg copper rod 8-20mm

-

Technology:

-

Upward casting

-

Raw material:

-

Cathode Copper and scrap copper

-

Feature:

-

High Efficency

-

Capacity:

-

600-12000T/Year

-

Type:

-

Upward type

-

Item:

-

12000T/Year

-

Fuel:

-

Electricity

Quick Details

-

Place of Origin:

-

China

-

Weight (KG):

-

8000

-

Marketing Type:

-

New Product 2022

-

Product name:

-

Upward Continuous Casting Copper Rod Making Machine

-

Application:

-

Making 8mm copper rod

-

Usage:

-

Castintg copper rod 8-20mm

-

Technology:

-

Upward casting

-

Raw material:

-

Cathode Copper and scrap copper

-

Feature:

-

High Efficency

-

Capacity:

-

600-12000T/Year

-

Type:

-

Upward type

-

Item:

-

12000T/Year

-

Fuel:

-

Electricity

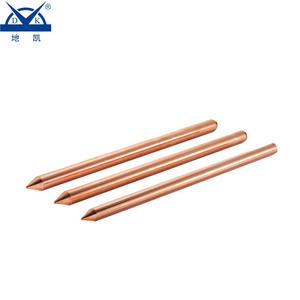

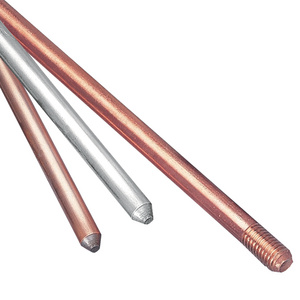

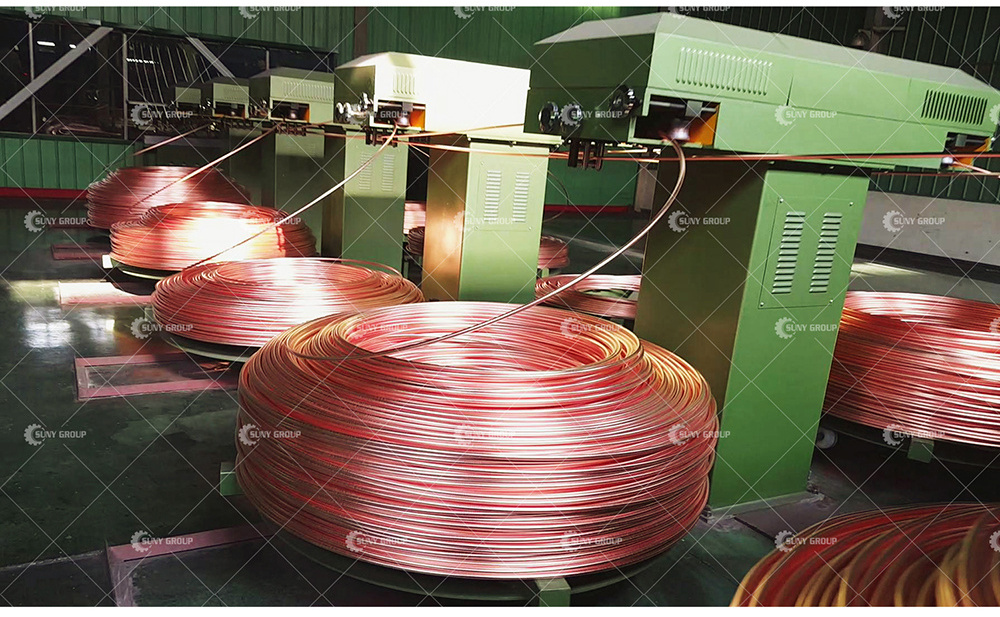

PRODUCT APPLICATION

Upward continuous casting machinery ( up cast line )

Upward Copper Rod Continuous Casting Full Plant is used to produce the long and bright oxygen-free copper rod with the diameter

from 8 to 25mm. Large-length bright oxygen-free copper tube blanks and large-length bright oxygen-free copper slabs.

As a conductive material with high conductivity and low oxygen content, the oxygen-free copper rod is widely used in wire,

cable,electromagnetic wire and other industries.

Upward Copper Rod Continuous Casting Full Plant is used to produce the long and bright oxygen-free copper rod with the diameter

from 8 to 25mm. Large-length bright oxygen-free copper tube blanks and large-length bright oxygen-free copper slabs.

As a conductive material with high conductivity and low oxygen content, the oxygen-free copper rod is widely used in wire,

cable,electromagnetic wire and other industries.

FINAL PRODUCT STANDARD

|

Raw Materials

|

The raw materials should meet the requirements of GB/T467-2010 cathode copper No.1 standard copper Cu-CATH-2

|

|

Battery Cover Remover

|

2200*2000*1300 mm

|

|

Copper Rod

|

Copper rod technical indicators should meet the GB/T3952-2008 standard

|

|

Density

|

~8.9Kg/dm3

|

|

Tensile Strength

|

>170N/mm2

|

|

Soft Electrical Conductivity

|

>100% IACS ( 2m2n Flexble Wire )

|

|

Soft Electrical Resistivity

|

>0.15328Ωg/m2

|

|

Elongation

|

>37%

|

|

Oxygen Content

|

≤20ppm

|

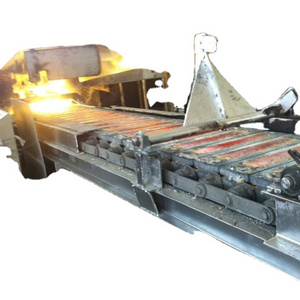

PROCESS DETAILS

Step 1.

Cathode copper is directly added to the melting furnace and melted into a liquid by power frequency induction;

Step 2. After melting, the copper liquid will automatically and smoothly overflow into the intermediate holding furnace through the

transition chamber;

Step 3. The copper liquid has a stable reduction process by the covered surface of charcoal;

Step 4 . After the reduction, the copper liquid is rapidly crystallized into a cast rod through a crystallizer through the continuous

casting machine in the holding furnace;

Step 5 . Every casting rod is equipped with a controller and a torsion bar machine.The casting rod is led from the continuous casting

machine to the controller and the torsion bar through the regulating wheel device to form a circle. After the completion of the

circle, the casting rod is cut and hoisted away for the next process.

Step 2. After melting, the copper liquid will automatically and smoothly overflow into the intermediate holding furnace through the

transition chamber;

Step 3. The copper liquid has a stable reduction process by the covered surface of charcoal;

Step 4 . After the reduction, the copper liquid is rapidly crystallized into a cast rod through a crystallizer through the continuous

casting machine in the holding furnace;

Step 5 . Every casting rod is equipped with a controller and a torsion bar machine.The casting rod is led from the continuous casting

machine to the controller and the torsion bar through the regulating wheel device to form a circle. After the completion of the

circle, the casting rod is cut and hoisted away for the next process.

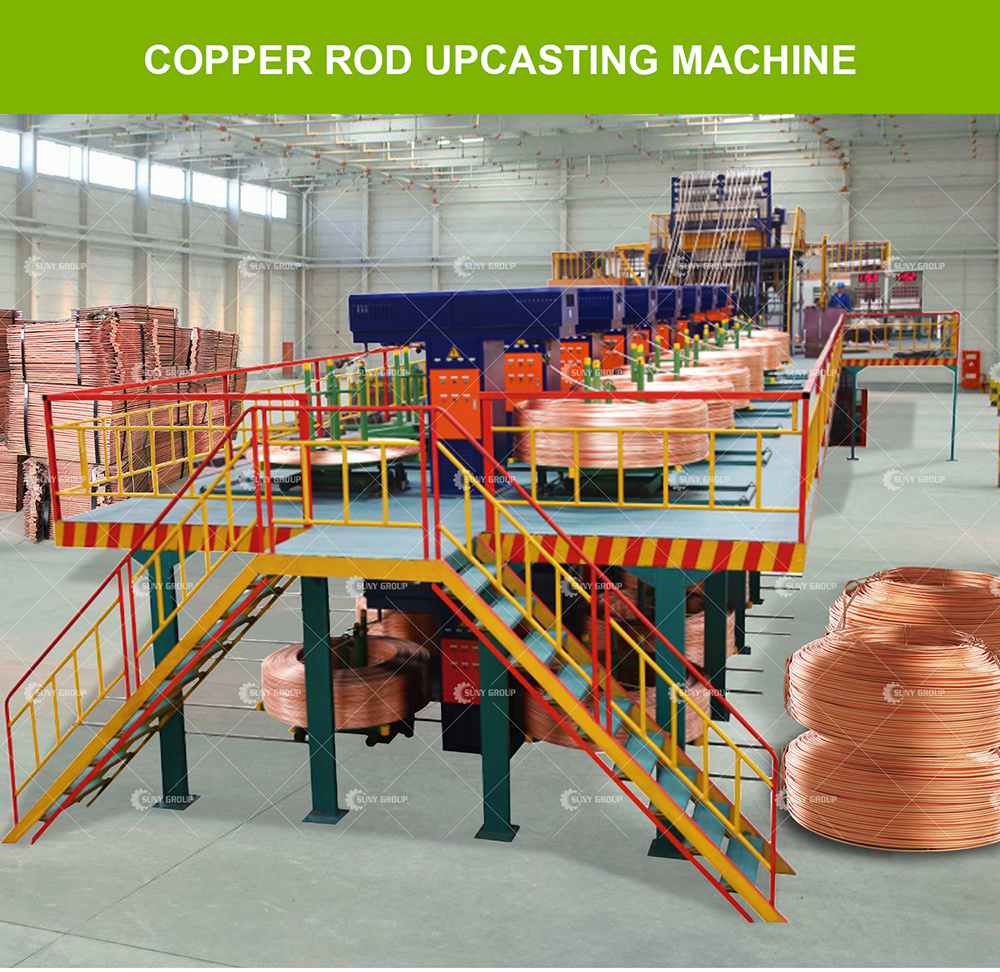

TECHNICAL PARAMETERS

|

Capacity

|

3000 - 12000T/Year

|

|

Furnace Number

|

2 Melting Furnace+1 Heat Preservation Furnace

|

|

Casting Rod Number

|

24 Pcs

|

|

Casting Rob Diameter

|

φ8mm ~ φ20mm

|

|

Upward Speed

|

6.0 ~ 2800mm/min

|

|

Upward Circular Pitch

|

3-6mm ( Adjustable )

|

|

Traction Frequency

|

0 ~ 800 times/time

|

|

Traction Way

|

Servo Motor Tranction

|

|

Winding Specification

|

φ1000xφ1550x800 ( mm )

|

|

Voltage

|

380V, 50Hz, 3Phase

|

|

Melting Copper Speed

|

1550 Kg/H

|

|

Maximum Operating Power

|

≤560 Kw

|

|

Power Consumption

|

≤330 Kwh/T

|

DEEP PROCESSING EQUIPMENT

CUSTOMER COOPERATION

Our company can offer you whole processing solution for the copper, such as copper separator, copper electrolysis, copper bar production line etc, and we will offer you the professional installing and training service, to help you to build a perfect copper recycling factory.

Hot Searches