- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Furui

-

Voltage:

-

380v

-

Power (kW):

-

37

-

Weight (T):

-

4.5

-

Name:

-

double shaft shredder waste plastic

-

Application:

-

Recycle Waste Plastic

-

Function:

-

Plastic Cutter Grinder Crusher Shredder Machine

-

Color:

-

Client's Requirements

-

Speed:

-

20-25r/min

-

Crushing chamber size:

-

400*330mm

-

Diameter:

-

160mm

-

Production:

-

1-2t/h

-

Power:

-

5.5kw

-

Blade number:

-

27

-

Marketing Type:

-

Other

Quick Details

-

Max.Production Capacity (kg/h):

-

10000

-

Place of Origin:

-

Henan, China

-

Production Capacity (kg/h):

-

500 - 10000 kg/h

-

Brand Name:

-

Furui

-

Voltage:

-

380v

-

Power (kW):

-

37

-

Weight (T):

-

4.5

-

Name:

-

double shaft shredder waste plastic

-

Application:

-

Recycle Waste Plastic

-

Function:

-

Plastic Cutter Grinder Crusher Shredder Machine

-

Color:

-

Client's Requirements

-

Speed:

-

20-25r/min

-

Crushing chamber size:

-

400*330mm

-

Diameter:

-

160mm

-

Production:

-

1-2t/h

-

Power:

-

5.5kw

-

Blade number:

-

27

-

Marketing Type:

-

Other

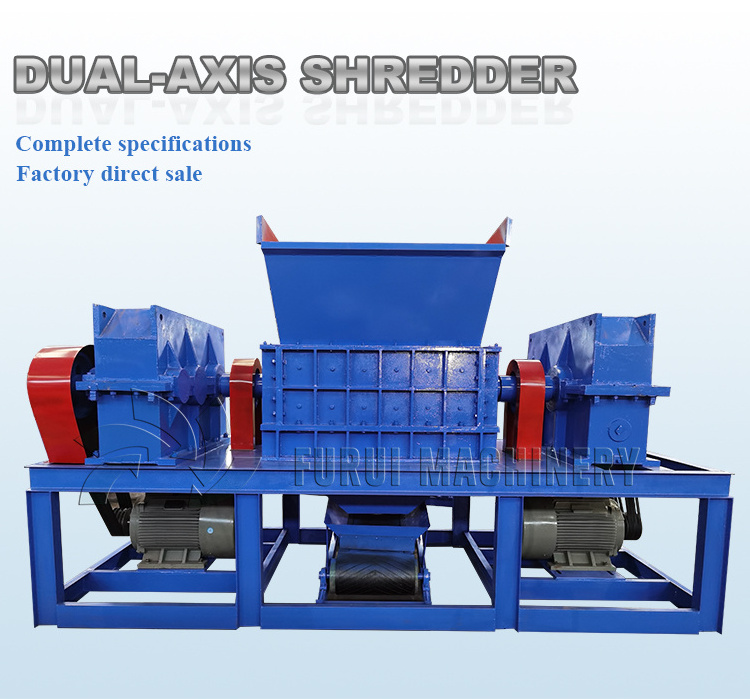

Wholesale double shafts shredder blade/agricultural waste compost shredder

Double shaft shredder uses shearing, tearing, and extrusion working principles to process materials, crush different solid wastes, and has good effects on hard and soft materials. It is commonly used in environmental protection industries such as garbage disposal, resource recycling, and waste incineration pretreatment.

Double shaft shredder all adopt PLC automatic control system, with automatic reversal control system inoverload condition. The shredder is easy to disassemble and change cutter blade and suitable for tearing large, extra thick and hard materies.

Specification of double shafts shredder blade:

| Model | FR-400 | FR-600 | FR-800 | FR-1000 | FR-1200 |

| Production | 1-2t/h | 2-4t/h | 4-6t/h | 6-8t/h | 8-10-15t/h |

|

Diameter |

160mm | 260mm | 320mm | 400mm | 450mm |

| Power | 5.5kw | 7.5kw*2 | 18.5kw*2 | 37kw*2 | 55kw*2 |

| Thickness | 14.5mm | 20mm | 20mm | 25mm | 30mm |

| Blade number | 27 | 30 | 40 | 40 | 40 |

| Speed | 20-25r/min | 20-25r/min | 20-25r/min | 20-25r/min | 20-25r/min |

| Crushing chamber size | 400*330mm | 600*500mm | 800*700mm | 1000*800mm | 1200*900mm |

| Shape size | 1160*550*450 | 2660*1250*1950 | 3800*1300*1850 | 4200*1400*1950 | 4400*1600*2100 |

| Weight | 550kg | 2300kg | 3500kg | 4500kg | 5800kg |

Scope of application

1. All kinds of hollow containers: plastic beverage cans, plastic barrels, iron barrels, packaging

boxes, packaging barrels;

2. Waste household appliances: TV sets, washing machines, refrigerator shells;

3. Pipes: large-scale pipes, fittings, RE pipes;

4. Waste formwork: wooden pallet, plastic pallet, forklift pallet;

5. Waste tyres: small wheel tyres, truck tyres;

6. Scrap metal: automobile shell, aluminium alloy, scrap cast aluminium, engine shell, lead and

steel plate with thickness less than 5 mm;

7. Kitchen garbage, household garbage, medical garbage, household straw and garden garbage

8. Rubber head material, paper mill rope, waste paper, corrugated paper.

Double shaft shredder, also known as shearing shredder, reduces material size by shearing, tearing and extrusion. This shredder is mainly used for recycling plastic such as packing belt, tire, film, woven bag and waste fishing net. Using two-axis independent drive, unique tool axis structure and four-corner rotary tool, in the production process of low speed and high torque,there will be no phenomenon of wrapping shaft or stuck equipment, thus improving production efficiency.

Equipment features:

1:Heavy moving knife, high crushing efficiency moving knife and fixed knife are cast with alloy steel, strong, long service life, thick iron frame plate, can resist high torque, very strong.

2:Easy to adjust, low maintenance cost, economical and durable

3:Unit output is the theoretical throughput, and the specific use should be based on the actual density and shape of crushed matter.

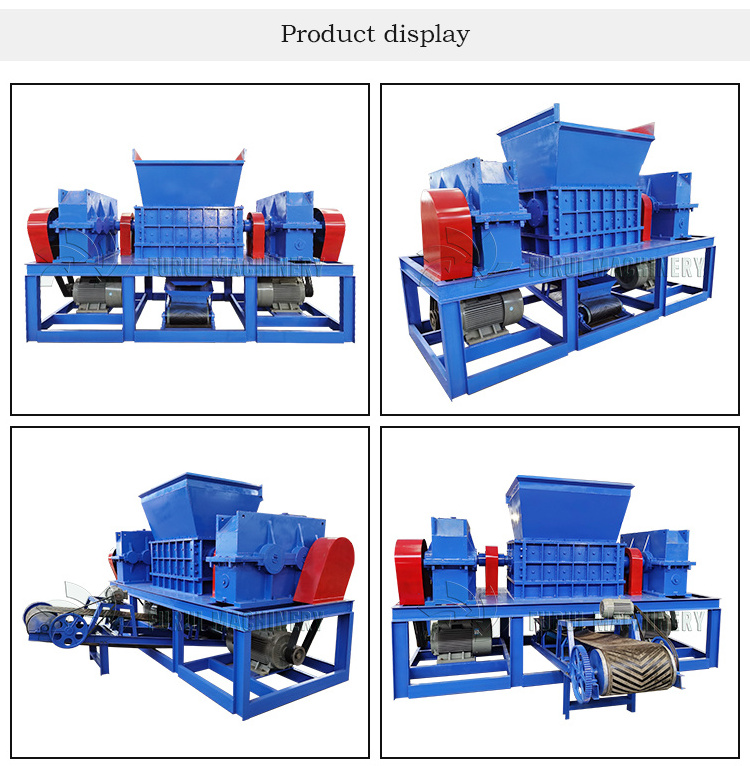

More photos:

1. After-sale service:

We provide 12 months' warranty(After the warranty, we can provide life-long repair service).

2. Customization:

We make customized diesel engine crusher plastic machine.

3. Design:

* Mechanical Design: We make a good mechanical design to ensure they can operate without

any frictions, so that it can have a long service life.

* If you have some special scenes in your mind, you can draw it down and we can produce the your pictures.

Also, we can make the movie scenes!

* Inspection: we have a strict Quality Inspection Department, and every machine would be tested before delivery.

If you are interested in our products, please contact me , we will reply within 24 hours!!!