- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

nitinol

-

Product name:

-

Nitinol wire Shape Memory Alloy Superelastic Niti Wires Price Per KG

-

Keyword:

-

Niti wire

-

MOQ:

-

1 KGs

-

Grade:

-

nickle titanium alloy

-

Ti (Min):

-

45

-

Strength:

-

895

-

Surface:

-

Polished, ground, oxide surface

-

Density:

-

6.45 g/cm³

-

Elongation:

-

25-50%

-

Melting point:

-

1310°C

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Return and Replacement

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

nitinol

-

Product name:

-

Nitinol wire Shape Memory Alloy Superelastic Niti Wires Price Per KG

-

Keyword:

-

Niti wire

-

MOQ:

-

1 KGs

-

Grade:

-

nickle titanium alloy

-

Ti (Min):

-

45

-

Strength:

-

895

-

Surface:

-

Polished, ground, oxide surface

-

Density:

-

6.45 g/cm³

-

Elongation:

-

25-50%

-

Melting point:

-

1310°C

Products Description

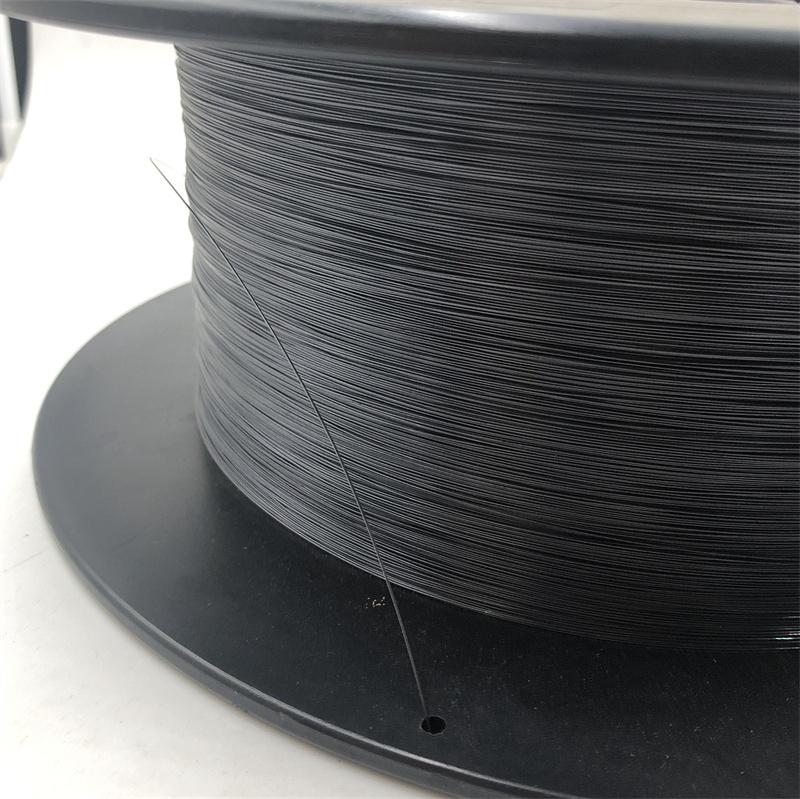

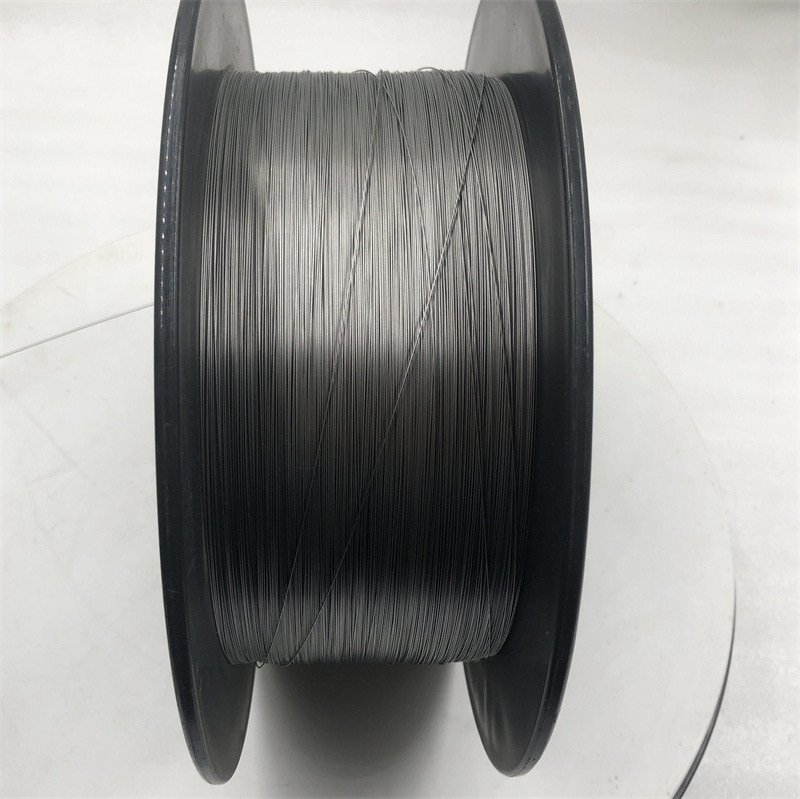

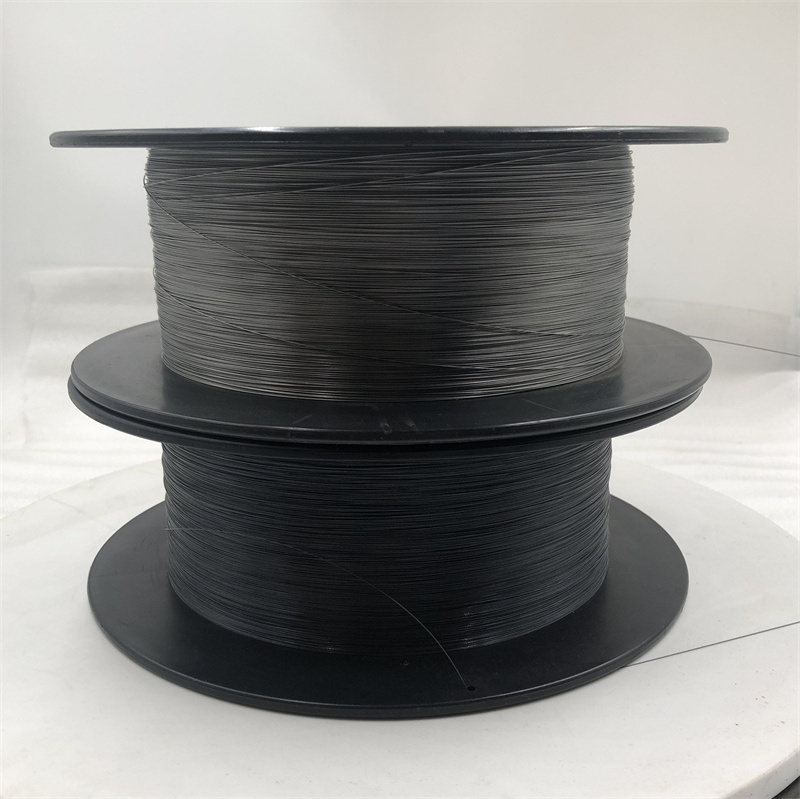

Nitinol wire Shape Memory Alloy Superelastic Niti Wires Price Per KG

Nitinol is a nickel-titanium alloy with super elasticity and shape memory properties. Shape memory refers to the ability of Nitinol to undergo deformation at one temperature, then recover its original, under formed shape upon heating above its transformation temperature. Super elasticity occurs at a narrow temperature range just above its transformation temperature; in this case, no heating is necessary to cause the under formed shape to recover, and the material exhibits enormous elasticity, some 10-30 times that of ordinary metal.

Nickel Titanium (also known as Nitinol or NiTi) is in the unique class of shape memory alloys.

A thermoelastic martensitic phase transformation in the material is responsible for its extraordinary properties. Nitinol alloys are typically made of 55%-56% Nickel and 44%-45% Titanium. Small changes in composition can significantly impact the properties of the material.

There are two primary categories of Nitinol.

The first, known as "SuperElastic", is characterized by extraordinary recoverable strains and kink resistance.

The second category, "Shape Memory" alloys, is valued for the Nitinol's capacity to recover a pre-set shape when heated above its transformation temprature. The first category is often used for orthodontics (braces, wires, etc) and eyeglasses. SZNK makes shape memory alloys, which are primarily useful for actuators, used in many different mechanical devices.

Product Introduction

|

Alloy

|

|

Chemical

composition |

|

|

|

Af(fully annealed)

|

Min. elongation to failure [%]

|

Max. Residual

elongation after 6% strain [%] |

Main

Applications |

||||

|

Superelastic

Ni-Ti alloy |

TiNi-SS

|

Ti-50.8at%

|

|

|

|

-5°C ± 5°C.

|

10

|

0.1

|

Eyeglass

Frames, Cellular Phone Antennae, Bra Underwire |

||||

|

|

TN3

TNC |

TiNiVAl

TiNiCr |

|

|

|

-40°C ~50°C

|

10

|

0.1

|

|

||||

|

Body temperature

Ni-Ti alloy |

TiNi-YY

|

Ti-50.7at%Ni

|

|

|

|

Functional(Af=33±3)

|

15

|

0.1

|

Implantable

devices, Bone staples Vascular Stents |

||||

|

|

Ti-Ni-01

|

55.6~55.8 wt%Ni

|

|

|

|

20-40

|

15

|

0.1

|

Guide wires,

Stents Orthodontic Arches |

||||

|

High temperature

Ni-Ti alloy |

Ti-Ni-02

|

54.8~55.5wt%Ni

|

|

|

|

45 - 95

|

10

|

0.1

|

Implantable

active devices, Surgical tools, Thermostats Coffeepots |

||||

|

|

TiNiCu

|

TiNiCu

|

|

|

|

As-Ms ≤ 5

|

10

|

0.1

|

|

||||

|

Alloy code

|

F

|

G

|

I

|

J

|

H

|

|

Main composition

mass%Ni |

44.0Ti

55.8Ni 0.2Cr |

44.0Ti

55.2Ni 0.8Cr |

50.0Ti

45.0Ni 5.0Cu |

50.0Ti

49.7Ni 0.3V |

47.0Ni

44.0Ti 9.0Nb |

|

*Active Af after

heat treatment, °C |

Similar to binary

Nitinol D with higher strength |

Similar to ternary NiTi0.2Cr

with higher strength |

42+/-5

|

-32+/-6

|

142+/-10

|

Application

APPLICATION

* Heat engines

* Resilient glass frames

* Orthodontic arc wire

* Medical devices

* Actuators

* High reliability couplings

* Temperature control system couplings

Transportation and Packaging

Packaging and shipping

Nitinol wire Shape Memory Alloy Superelastic Niti Wires Price Per KG packed with waterproof paper or weave bag, into pallets or wooden case. Special packaging requirements can also be accommodated. OEM is also acceptable.

Hot Searches