- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

EH004

-

Hardness:

-

From 50-90 shore A

-

Size:

-

Customize size

-

Color:

-

red

-

process:

-

Extrusion

-

Reinforcement:

-

nylon,braided,steel

-

Application:

-

Auto

-

MOQ:

-

100pcs

-

Surface:

-

Smooth Finish

-

Logo:

-

Custom Logo

-

Certification:

-

RoHS

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Bestseal

-

Model Number:

-

EH004

-

Hardness:

-

From 50-90 shore A

-

Size:

-

Customize size

-

Color:

-

red

-

process:

-

Extrusion

-

Reinforcement:

-

nylon,braided,steel

-

Application:

-

Auto

-

MOQ:

-

100pcs

-

Surface:

-

Smooth Finish

-

Logo:

-

Custom Logo

-

Certification:

-

RoHS

Recommend Products

|

Production information

|

|

|

Description

|

Rubber hose with fabric reinforced

|

|

Material

|

EPDM, NBR and SILICONE with fabric reinforced

|

|

Compound material

|

Meet ASTM D2000 and can be ROSH, REACH compliance

|

|

Hardness

|

From 20 ~ 90 shore A

|

|

Color

|

As per request

|

|

Size

|

Custom size

|

|

Package

|

PE bag, Carton, Pallet

|

|

Leadtime

|

8 days for sample, 12~18 days for mass product

|

|

Advantage

|

1. Strong bonded between rubber and fabric 2. 100% leaking check before packing

3. 100% Hand-made for silicone hose

4. We are a valued rubber hose's supplier to Golden Dragon Bus

|

FAQ

Q 1. What's the payment term?

A: We accept T/T 50% deposit and 50% balance before delivery or L/C at sight, Western Union, Trade Assurance, Paypal is also accepted.

Q 2. What is the normal lead time for product orders?

A: Average lead times for prototype / first article are around 2 weeks, if tooling is involved, lead time for production tooling

is around 10 days, average production time after sample approval is 2-3 weeks.

Q 3. What is your standard packing?

A: All the goods will be packed by PP bag and then carton box. Special packing method can be accepted when needed.

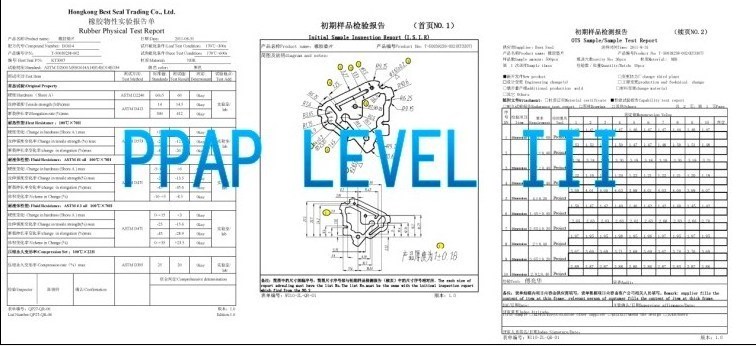

Q 4. what kind of certificates you have ?

A1: We have ISO9001:2015.

A2: We have various rubber compounds approved by Food grade, NSF, KTW, W270, WRAS, ACS, AS4020, EN681, EN549, ROHS and REACH.

Q 5: How to check the quality of the bulk order?

A1: We provide pre-production samples before mass production for all customers if needed.

A2: We provide quality certs such as measurement report, material data sheet to all customers before delivery.

A3: We accept third party inspection such as SGS, TUV, INTERTEK, BV, etc.

Q 6: How to select the raw compound for my application?

A: With years of experience working with a variety of material, we can help select the material that will best suit your needs

while keeping material costs in mind.

Q 7: Do you use any international standards for the rubber products?

A: Yes, we mainly use ASTM D2000 standard to define the quality of the rubber materials, tolerances as per ISO3302, RMA, etc.

Q 8:Can you supply different color materials?

A: Yes, we can produce custom molded rubber and silicone rubber products in different colors, the color code will be required in

case of an order.

Q9: What materials are available to produce from your side?

A: NBR, EPDM, SILICONE, FKM, NEOPRENE(CR), NR, IIR, SBR, ACM, AEM, Fluorosilicone(FVMQ), FFKM, Liquid Silicone, Sponge, etc.

Q 10: What is the life expectancy of the rubber seal?

A: Product life is contingent upon many factors, including environment, cycles, pressure, etc. Best Seal cannot predict seal life

under all the varying conditions of operation. Accellerated life testing may be performed by customer to determine expected life,

but must be conducted in dynamic application.

Q11: Does Best Seal provide maintenance on tooling?

A: Best Seal maintains all tooling and will replace as needed.

A: We accept T/T 50% deposit and 50% balance before delivery or L/C at sight, Western Union, Trade Assurance, Paypal is also accepted.

Q 2. What is the normal lead time for product orders?

A: Average lead times for prototype / first article are around 2 weeks, if tooling is involved, lead time for production tooling

is around 10 days, average production time after sample approval is 2-3 weeks.

Q 3. What is your standard packing?

A: All the goods will be packed by PP bag and then carton box. Special packing method can be accepted when needed.

Q 4. what kind of certificates you have ?

A1: We have ISO9001:2015.

A2: We have various rubber compounds approved by Food grade, NSF, KTW, W270, WRAS, ACS, AS4020, EN681, EN549, ROHS and REACH.

Q 5: How to check the quality of the bulk order?

A1: We provide pre-production samples before mass production for all customers if needed.

A2: We provide quality certs such as measurement report, material data sheet to all customers before delivery.

A3: We accept third party inspection such as SGS, TUV, INTERTEK, BV, etc.

Q 6: How to select the raw compound for my application?

A: With years of experience working with a variety of material, we can help select the material that will best suit your needs

while keeping material costs in mind.

Q 7: Do you use any international standards for the rubber products?

A: Yes, we mainly use ASTM D2000 standard to define the quality of the rubber materials, tolerances as per ISO3302, RMA, etc.

Q 8:Can you supply different color materials?

A: Yes, we can produce custom molded rubber and silicone rubber products in different colors, the color code will be required in

case of an order.

Q9: What materials are available to produce from your side?

A: NBR, EPDM, SILICONE, FKM, NEOPRENE(CR), NR, IIR, SBR, ACM, AEM, Fluorosilicone(FVMQ), FFKM, Liquid Silicone, Sponge, etc.

Q 10: What is the life expectancy of the rubber seal?

A: Product life is contingent upon many factors, including environment, cycles, pressure, etc. Best Seal cannot predict seal life

under all the varying conditions of operation. Accellerated life testing may be performed by customer to determine expected life,

but must be conducted in dynamic application.

Q11: Does Best Seal provide maintenance on tooling?

A: Best Seal maintains all tooling and will replace as needed.

Hot Searches