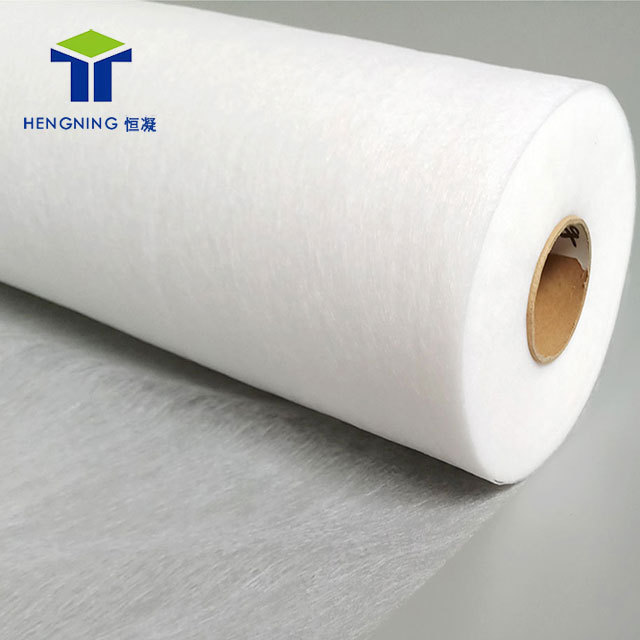

Here are some features of our hot melt adhesive web film:

a. H

igh intensity and strong bonding;

b. Excellent washing& dry cleaning performance;

c. Uneasy to change shape;

d. Good breath ability;

e. Eco-friendly.

f. Accepted OEM and ODM, colors are customized.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Hengning

-

Model Number:

-

HE80

-

Type:

-

hot melt adhesive web

-

Model name:

-

hot melt polyurethane adhesive

-

Width:

-

10-3200mm

-

Thickness:

-

12-150g

-

Melting point:

-

105 centigrade

-

Press time:

-

10-30s

-

Press temperature:

-

120-125 centigrade

-

Press:

-

1.5-3.0 kgf/m2

-

Optional types:

-

PA, PES, TPU and EVA

-

Optional colors:

-

Transparent or other

-

Certifications:

-

ISO9001, ISO14001

Quick Details

-

CAS No.:

-

0

-

EINECS No.:

-

0

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Hengning

-

Model Number:

-

HE80

-

Type:

-

hot melt adhesive web

-

Model name:

-

hot melt polyurethane adhesive

-

Width:

-

10-3200mm

-

Thickness:

-

12-150g

-

Melting point:

-

105 centigrade

-

Press time:

-

10-30s

-

Press temperature:

-

120-125 centigrade

-

Press:

-

1.5-3.0 kgf/m2

-

Optional types:

-

PA, PES, TPU and EVA

-

Optional colors:

-

Transparent or other

-

Certifications:

-

ISO9001, ISO14001

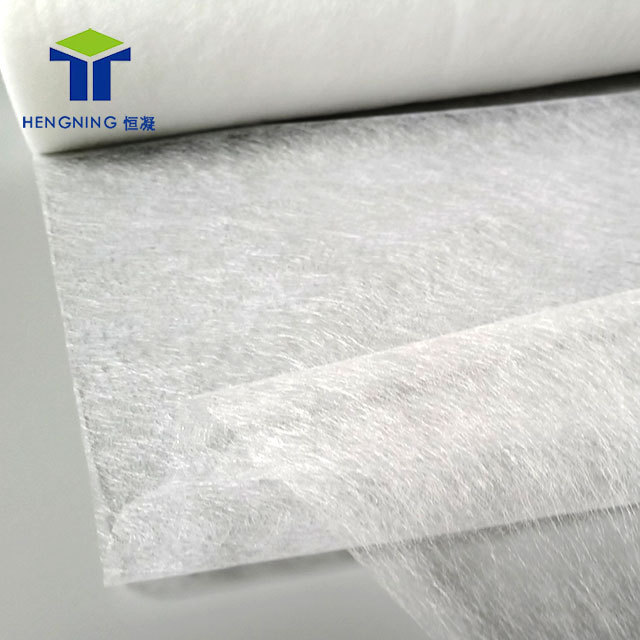

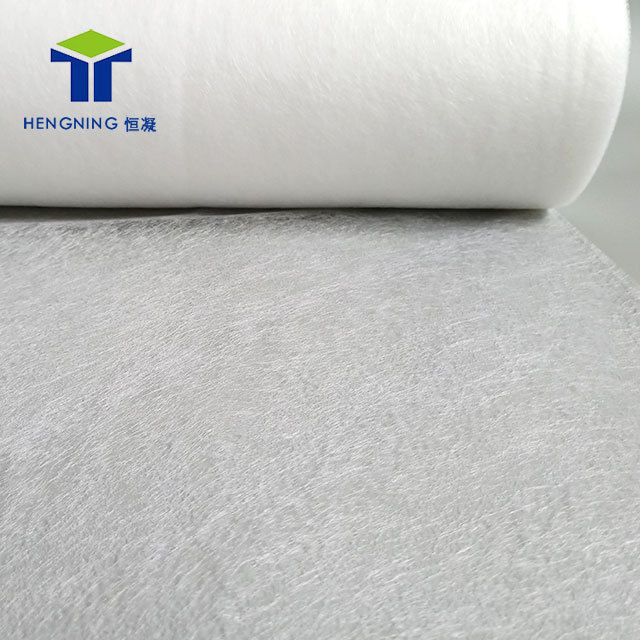

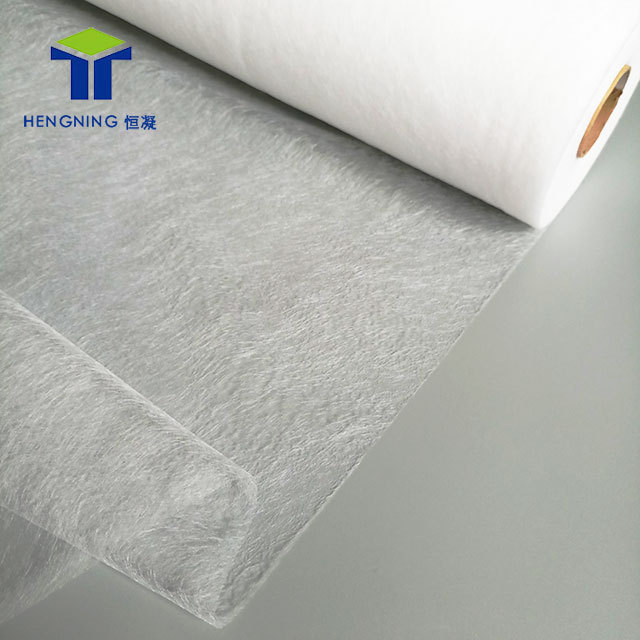

Products Description

Hot melt adhesive web film is a good product with high bonding ability, which are widely used in many indusrties, such as fabric, leather, metal, plastic, microfiber, non-woven fabric, wooden board, paper, etc.

The advantages of the hot melt adhesive film when compare to traditional glue bonding:

1. Eliminate the complicated process of glue application and do not need the related equipments;

2. Bonding fastly, heating and cooling, stick firmly;

3. The bonding fastness to textiles, leather, fabrics and glass fiber products is better than the glue with the same price;

4. Eco friendly, no harm to the environment and human body;

5. Do not need to worry about glue leakage during the bonding, and thematerials will be clean, tidy and no peculiar smell after bonding;

6. The bonded material will not fall off, wrinkle, or foam after washing and dry cleaning.

2. Bonding fastly, heating and cooling, stick firmly;

3. The bonding fastness to textiles, leather, fabrics and glass fiber products is better than the glue with the same price;

4. Eco friendly, no harm to the environment and human body;

5. Do not need to worry about glue leakage during the bonding, and thematerials will be clean, tidy and no peculiar smell after bonding;

6. The bonded material will not fall off, wrinkle, or foam after washing and dry cleaning.

|

Different materials specification

|

|

|

|

|

|

|

|

|||||||

|

Type

|

Model number

|

Width

(mm) |

Thickness

(g) |

Melting point

(Centigrade) |

Press time

(s) |

Press temperature

(Centigrade) |

Press

(kgf/m2) |

|||||||

|

PA

|

HA120

|

10-3200

|

5-150

|

120

|

10-30

|

135-140

|

1.5-3.0

|

|||||||

|

|

HA105

|

10-3200

|

8-150

|

105

|

10-30

|

120-125

|

1.5-3.0

|

|||||||

|

|

HA95

|

10-3200

|

8-150

|

95

|

10-30

|

110-115

|

1.5-3.0

|

|||||||

|

PES

|

HP125

|

10-3200

|

10-150

|

125

|

10-30

|

140-145

|

1.5-3.0

|

|||||||

|

|

HP160

|

10-3200

|

10-150

|

160

|

10-30

|

175-180

|

1.5-3.0

|

|||||||

|

TPU

|

HT105

|

10-3200

|

12-150

|

105

|

10-30

|

120-125

|

1.5-3.0

|

|||||||

|

|

HT70

|

10-3200

|

10-150

|

70

|

10-30

|

85-90

|

1.5-3.0

|

|||||||

|

EVA

|

HE80

|

10-3200

|

10-150

|

80

|

10-30

|

95-100

|

1.5-3.0

|

|||||||

Hot Searches