- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V, 50HZ

-

Power:

-

80KW

-

Dimension(L*W*H):

-

4.5 Cubic Meter

-

Weight (KG):

-

28

-

After Warranty Service:

-

Video Technical Support Online Support

Quick Details

-

Machine Type:

-

Plasma spraying machine SX-80, Spray Booths, Plc Controller Programmable Logic Controller, Pre-treatment Equipment, Coating Equipment, Sandblasting Machine, surface coating machine

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SX

-

Voltage:

-

380V, 50HZ

-

Power:

-

80KW

-

Dimension(L*W*H):

-

4.5 Cubic Meter

-

Weight (KG):

-

28

-

After Warranty Service:

-

Video Technical Support Online Support

Brief Introduction

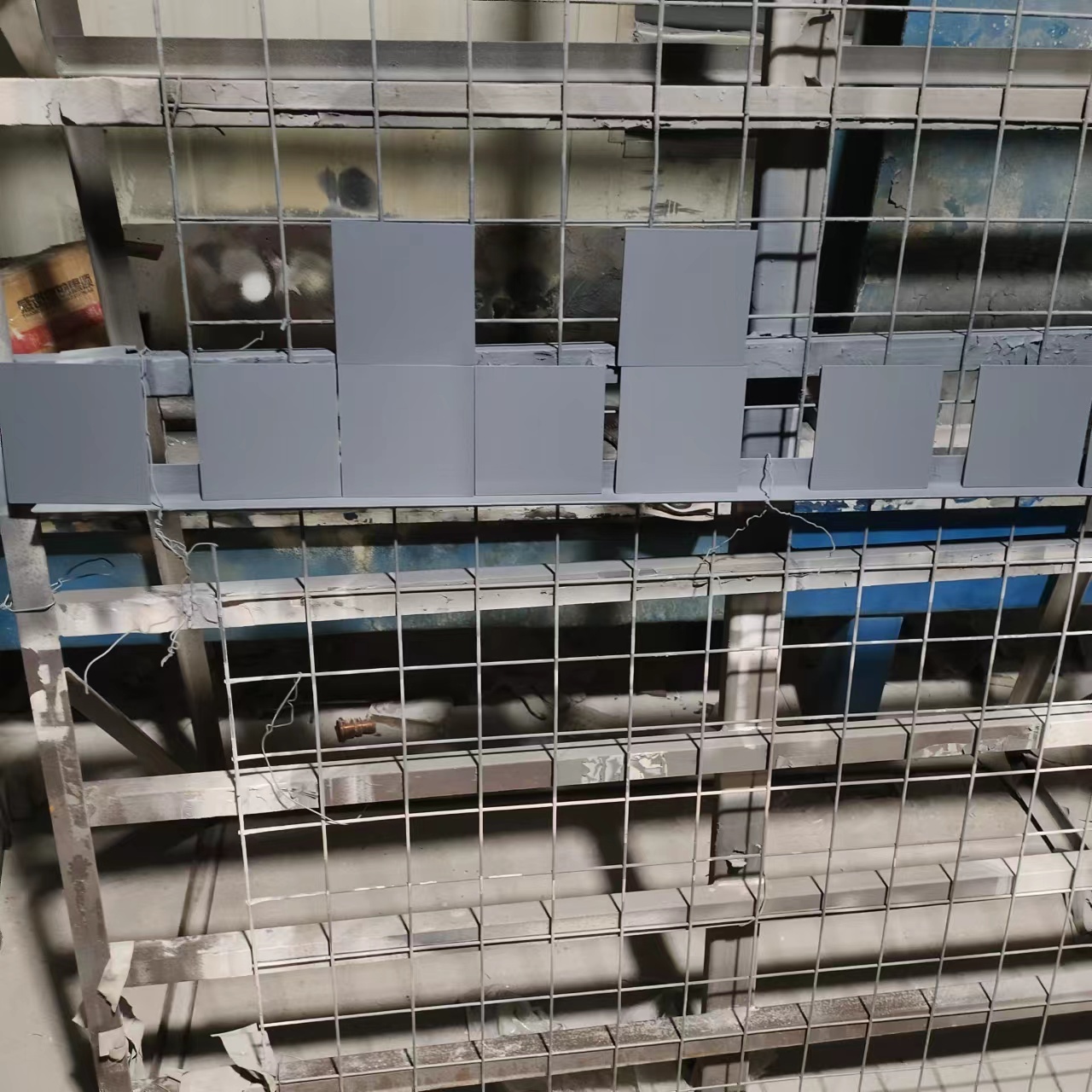

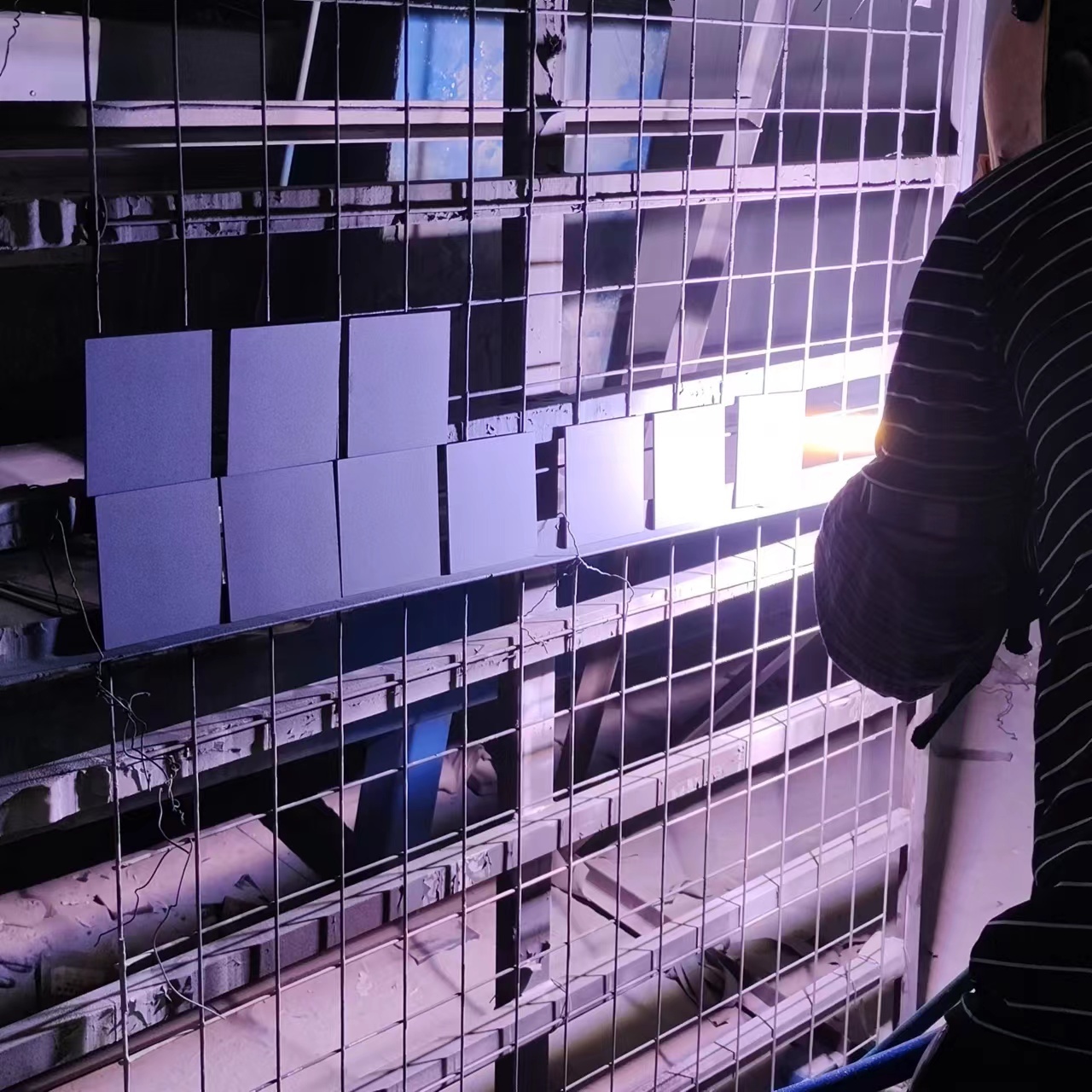

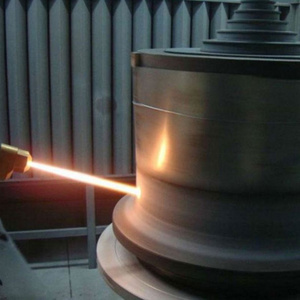

Configuration of SX-80 plasma spray equipment

SX-80 absorbs the experiences of PT-A3000 and METCO-9M plasma spray equipment and its performance level is equivalent to METCO-9M.

It mainly consists of main electricity supply, control cabinet, transfer box, powder feeder, spray gun and heat exchanger.

SX-80 Main power supply

silicon controlled rectifier, biggest input power 105kw, duty cycle 100%, biggest output power 80kw, electric current fluctuation range ±1-2%,when electric grid fluctuation is within ±15%, it can normally work.

SX-80 Transfer box

It’s the transfer center of spray equipment which connects power supply, control cabinet, heat exchanger and spray gun together.

It has high-frequency ignition, waterway and gas circuit alarm equipment insides. The box can be moved freely and the standard length of cable is 5m.

SX-80 Control cabinet

It’s the control center of the whole spray equipment. Single-phase 220V, 1KW, float flowmeter equipped, current and voltage, digisplay. Having manual, automatic and economic working modes.

Alarm and malfunction indicating function, generally it alarms under such conditions:

when the main and assistant gas pressure<0.3MPa or the main gas flow rate<30L/min

when water temperature>50°C or water flow rate<8L/min

SX-80 Powder feeder

Supply one set of two-tubed powder feeder

powder measurement scope: 5-200μm; powder repeated-feeding error rate<±1%

The two tubes can feed powder at the same time, feeding rate is between 20-150g/min.

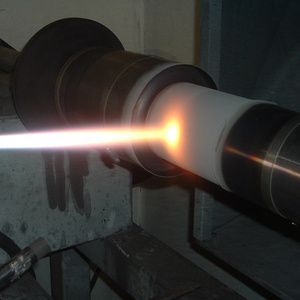

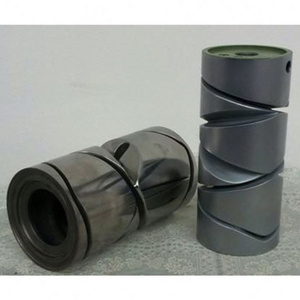

SX-80 Spray gun

Supply imitative METCO 9MB spray gun, main working gas is argon or nitrogen, assistant gas is hydrogen.

Working electric current: 100-800A.

Working voltage:

Ar+H2: 50-75V, N2+H2: 50-80V

1. Imitative 9MB machine-made gun

2. Imitative 9MB manual-made gun

3. Large-inner-hole spray gun

Supply spray gun accessories: GH,G,GP,GE type spray mouth, powder feeding and cooling air jetting-shelf, water cooled cable, electrode tip, insulator, obturating ring, special purpose tools.

Also we can supply customer imitative F4 spray gun (machine-made or manual-made) and accessories such as water cooled cable, spray mouth, electrode tip, powder feeding shelf, powder feeding mouth, obturating ring and special purpose tools.

SX-80 Heat exchanger

We provide two kinds of heat exchangers:

(1), water pumping heat exchanger has interior and exterior circulation. The interior circulation cools down the spray gun by distilled water, while the exterior circulation cools down the distilled water by tap water. We use imported water pump and below is the parameter of this heat exchanger:

Product information

1. Assembled with branded top quality and reliable parts such as Siemens PLC monitor & touch screen, SMC electromagnetic valve, air operated valve, Omron pressure pickup, Schneider electrical switching, Kewill flow valve, etc.

2. Powder feeder with precise adjustment of the feeding speed

3.Strong and durable control cabinet

4.Urgent stop button for safety

5.Customized Brand name / Logo available

6.Equipped with long-lasting and easy-to-use SX-80 Plasma spray torch

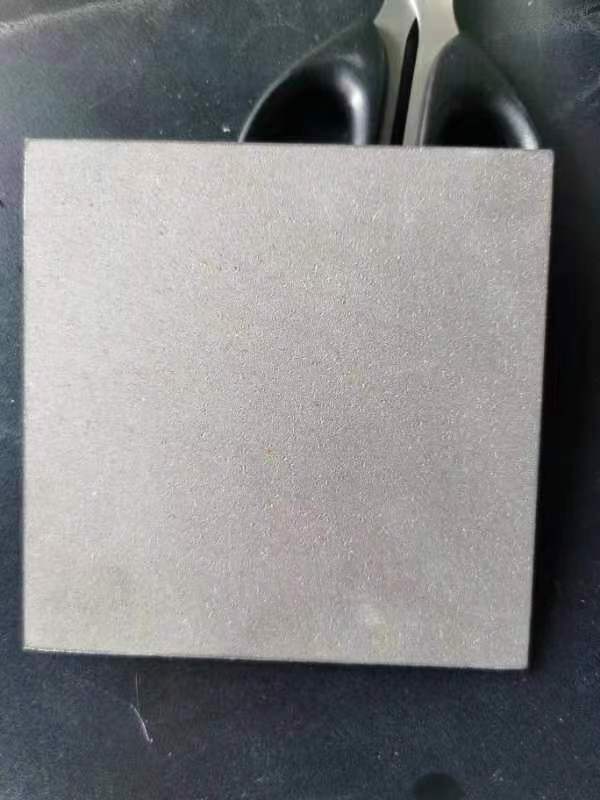

Typical coatings that can be applied are:

Iron, nickel & cobalt based alloys,

Titanium alloys,

Different kind of ceramic,

Hydroxyapatite,

Carbides, cements, oxides and other composite powder.

Properties of the coatings can be :

High hardness

Long-lasting

High temperature resist

Oxidation resistant

Anti Wear

Sliding, abrasives , erosion resistant

Chemical (Acid / Alkaline, etc.) resistance

Applications:

Due to its uniqueness of spraying technology, SX- plasma series can be used in many areas that require heat resistance such as exhaust system in racing cars. Also with the excellent longevity produced by plasma thermal coating equipment compared to other spray method, it's popular in bio-compatible implants coatings such as hip, knees, dental implant parts coating with hydroxyapatite and titanium alloy material in health and medical industry as well as blades and vanes, solid oxide fuel cells, and combustion chambers in other industries.

1. Assembled with branded top quality and reliable parts such as Siemens PLC monitor & touch screen, SMC electromagnetic valve, air operated valve, Omron pressure pickup, Schneider electrical switching, Kewill flow valve, etc.

2. Powder feeder with precise adjustment of the feeding speed

3.Strong and durable control cabinet

4.Urgent stop button for safety

5.Customized Brand name / Logo available

6.Equipped with long-lasting and easy-to-use SX-80 Plasma spray torch

Typical coatings that can be applied are:

Iron, nickel & cobalt based alloys,

Titanium alloys,

Different kind of ceramic,

Hydroxyapatite,

Carbides, cements, oxides and other composite powder.

Properties of the coatings can be :

High hardness

Long-lasting

High temperature resist

Oxidation resistant

Anti Wear

Sliding, abrasives , erosion resistant

Chemical (Acid / Alkaline, etc.) resistance

Applications:

Due to its uniqueness of spraying technology, SX- plasma series can be used in many areas that require heat resistance such as exhaust system in racing cars. Also with the excellent longevity produced by plasma thermal coating equipment compared to other spray method, it's popular in bio-compatible implants coatings such as hip, knees, dental implant parts coating with hydroxyapatite and titanium alloy material in health and medical industry as well as blades and vanes, solid oxide fuel cells, and combustion chambers in other industries.

Hot Searches