Located in Guangzhou, BDLF has been working on waterproof and other building materials since 2005. In 2010, our trademark of QianYu was registered. We always stick to the concept of innovation and environmental protection. In 2011, we are awarded The Best Supplier in our field. Our injection grouting pump was patented China's utility model patent products in 2013.We also developed new environmental protection materials, such as epoxy resin .

- Product Details

- {{item.text}}

Quick Details

-

Shape:

-

grouting pu packer

-

Connection:

-

injection packer

-

Usage:

-

Building Coating

-

Certificates:

-

ISO

-

Function:

-

Injection Resin

-

Gross weight per batch:

-

≥23.5KG

-

Selling Units:

-

1000pcs

Quick Details

-

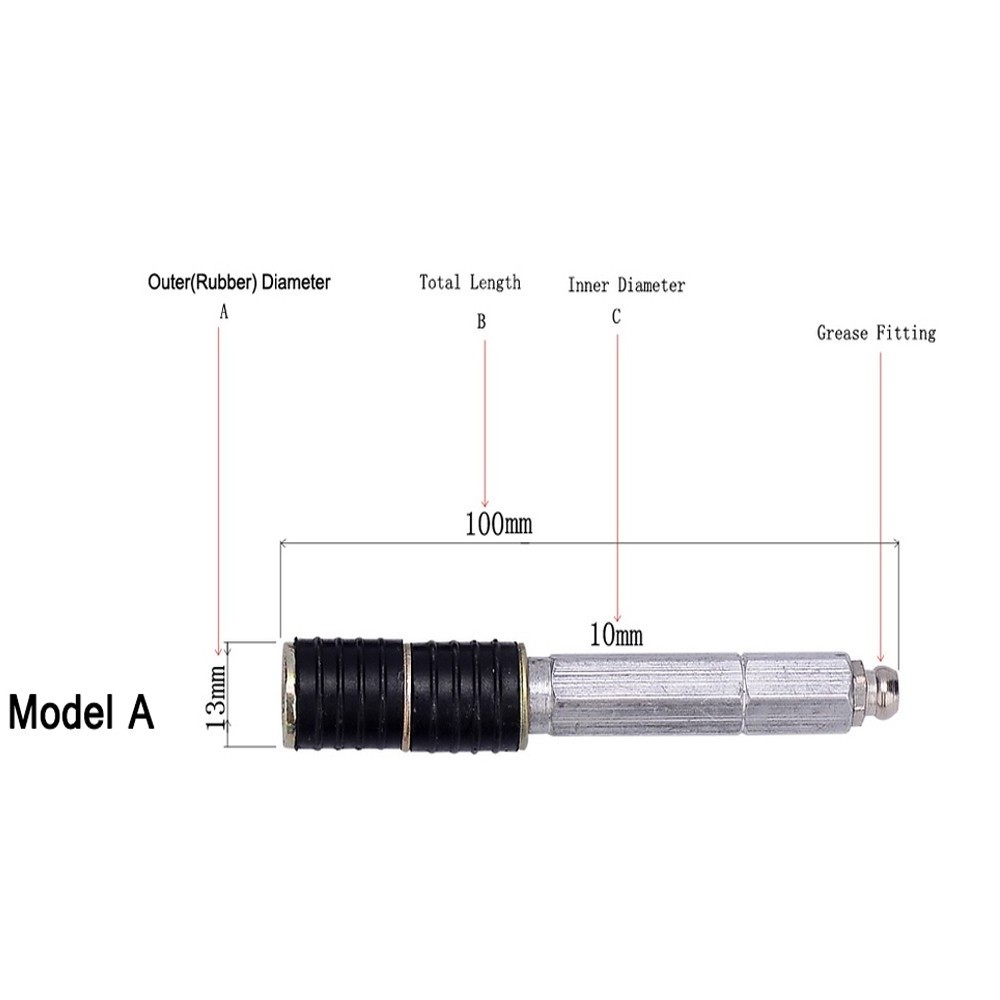

total length:

-

≤95mm

-

Diameter:

-

13mm

-

Open pressure:

-

30-40bar or100bar

-

Shape:

-

grouting pu packer

-

Connection:

-

injection packer

-

Usage:

-

Building Coating

-

Certificates:

-

ISO

-

Function:

-

Injection Resin

-

Gross weight per batch:

-

≥23.5KG

-

Selling Units:

-

1000pcs

A10 High-pressure polyurethane grout aluminum injection concrete packers waterproofing material

As an important part of the grouting machine,it's widely used in waterproofing of house decoration industry, especially used for injection of polyurethane foaming agent or epoxy resin into concrete cracks with the technology of high-pressure chemical grouting and plugging.

Advantage

1. The injection packer is under strict quality control.

2.It's simple and easy to use in the construction with high efficiency and not subject to seasons and weather.

3.The injection packer has a wide range of specifications including A-8,A-10,A-15,B-8,B-10, etc.

4.It suits for injection of polyurethane foam and epoxy resin.

5.It is widely used in building construction, concrete crack and water leaking stop.

The injection packer is under strict quality control.Under high and stable pressure, it can inject the chemical grout deep into the minor cracks of the concrete structure.

It is widely used in building construction, concrete crack and water leaking stop.

With mature grouting technology, the injection packer is suitable for various grouting materials,especially polyurethane foam and epoxy resin.

It's simple and easy to use in the construction with high efficiency and not subject to seasons and weather.

Precautions

1The machine will shake during transportation. Please tighten all the screws before using the machine.

2 It is strictly forbidden to infuse the slurry with granular components, such as resin mortar, cement mortar, non-shrinkage cement, etc.

3 It is forbidden to test the working pressure with a liquid without viscosity such as (toluene, acetone, water, etc.).

4 Use engine oil to test the pressure of the machine. If it is empty, the pressure gauge does not show pressure.

5 test method: pour the oil into the barrel of the machine, close the valve, the gun head is facing the outside, open the electric drill, when the pressure gauge shows the pressure of 300-400 kg, turn off the electric drill, open the valve, return the lubricating oil Go to the oil drum, you can, the pressure test is successful, please wear a work cap, gloves, and overalls during construction.

Cleaning and maintenance:

If the machine has been used, immediately use thinner (such as Tianna water, pine perfume, acetone, xylene, thinner) to clean the diluent, pour the thinner into the bucket, put the gun head into the bucket, and turn it on. Cycle cleaning, wash several times, ensure complete cleaning, spray the diluent, then pour the oil, the same method, cycle , maintenance machine.

Common construction methods and techniques

1.High-pressure grouting plugging construction method (complete construction video contact customer service) 1 inspection: carefully check the leaking parts, clean up the dirt near the leaking part, in order to grout

2.cloth hole: grouting hole in the water leakage part, the deep hole crack can be drilled oblique hole through the seam surface, the general hole distance is 10CM-30CM

3.Buried needle: embed a water stop needle and tighten with a T-wrench

4.Grouting: Determine the grouting pressure and grouting amount according to the specific conditions of the leaking part. The chemical grouting material is poured into the crack by a high-pressure grouting machine, and moved to the adjacent hole when a pure slurry appears near the pinhole.

5.Needle removal: After 48 hours, check whether there is water seepage at the leaking part. If there is no water seepage, the water stop needle will be broken, and the base surface will be closed and smoothed with polymer cement.

Construction technology structure cracks leak in different environments

1 Drill the hole at the left or right 2CM-5CM at the lowest point of the crack to the depth of the thickness of the structure, and drill from the low to the high. The hole distance is 20CM-30CM, and then bury it again after drilling to the highest point. Grouting water needles, because the general structure cracks are irregular, it is necessary to pay special attention to the intersection of the rupture surface when drilling, the grout will have an effect

2 After the setting of the grouting water stop needle is completed, it is poured with chemical grouting material until the grouting liquid is found to seep on the surface of the structure.

3 48 hours after the completion of the filling, the grouting needle can be removed

Concrete structure

Construction joint leaking

1 Drill the hole at the left or right 5CM-10CM at the lowest point of the construction joint to one-half of the thickness of the structure, and drill from the low to the high in the order. The hole distance is 20CM-30CM, and it is better to drill to the highest point and then bury it again. Water needle.

2 After the setting of the grouting water stop needle is completed, the chemical grouting material is injected into the high pressure perfusion machine until the grouting liquid is found to ooze out on the surface of the structure body. 3 After the filling is completed, the grouting and water stopping needle can be removed.

Honeycomb leaking

1 At the hive range, drill a hole every 25CM-30CM, the depth is one-half of the thickness of the structure, and then fill the grouting needle and tighten it.

2 After the water stop needle is set, the chemical grouting material is injected into the high pressure filling machine until the grouting liquid is found to ooze out on the surface of the structure, so that the water leakage problem can be solved. 3 After 48 hours of filling, the grouting needle can be removed.

Precautions for grouting machines

1 The connection between the machine includes: high pressure pipe and switch group, the connection between the high pressure pipe and the machine needs to be wrapped with raw tape.

2 The screw parts of the machine also need to be tightened to prevent the machine from falling apart or missing parts during high-pressure operation, including machine glue and handles.

3 The motor and the machine need to be placed in place without leaving a gap. Next, let's talk about a few important issues in the process of use.

4 Since the material injected by the machine cannot be in contact with water, the machine is strictly prohibited from washing with water.

5 machine maintenance is the key to cleaning (after washing with thinner, it is best to use vegetable oil or oil again, usually sold in hardware stores)

6 The last and most important problem is the safety of life. The machine belongs to high-pressure machinery. When the pressure is too high, it is necessary to stop the injection at the right time to prevent harm to yourself.

30 DAY GUARANTEE

Mortarsprayer.com offers a full refund less shipping if you are not satisfied with the performance of the tool. The sprayer must be returned within 30 days of receiving it.

WARRANTY

Full one-year warranty on parts and workmanship. Jets are considered consumable parts and are warranted for 90 days (although they should last the life of the tool if you keep them clean). If you have problems with your tool and need to return it for service.

SHIPPING

When you place an order, please choose a shipping method and pay for the order including the shipping fee. We will send the items within 7 days once your payment is completed.

Our products include many kinds of waterproof materials like PU injection grouting pump, waterproof membrane and other building machines like cement spraying machine, ect. They all meet the standard with ISO and are widely used in a lot of building projects in many other main cities of China. Besides, we keep friendly cooperation with companies from all over the world, especially Southeast Aisa.

As the competition is fierce gradually, not only do we keep improving the quality of our products, but also we try our best to promote the level of our service. Quality, practicability and honesty are what we persist in for years. With an energetic, efficient and powerful team, BDLF always gets ready to build a beautiful future with you with enthusiasm and confidence.

Why to choose us

1.We value every inquiry sent to us and ensure a quick competitive offer. If you order to us, we can promise the quality

2.We put your order into our tight production schedule to ensure you punctual delivery time and send shipping notice to you as soon as your order is shipped. We respect your feedback after you have received the goods.

3.Because we have more than 10 years of experience in waterproof industry, all our products conform to national standard! We can promise an excellent service and a prompt delivery! Your order is welcome at any time!

4. Our company promises: reasonable prices, short production time and satisfactory after-sales service

5.If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.