- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SAMHO

-

Model Number:

-

Thread Milling Cutter

-

Suitable for 1:

-

Alloy Steels,Prehardened Steels,Hardened Steels

-

Suitable for 2:

-

Carbon Steels,Copper,Titanium Alloys,Aluminum Alloys

-

Raw material:

-

Tungsten Steel

-

HRC:

-

65 Degrees

-

Usage:

-

CNC Machine Center

-

Flutes:

-

4 Flutes

-

MOQ:

-

5 Pieces

-

OEM:

-

Avaliable

-

Manufacture:

-

We are factory

-

Shipment:

-

DHL.TNT.UPS.FEDEX.EMS

Quick Details

-

Material:

-

Tungsten Steel

-

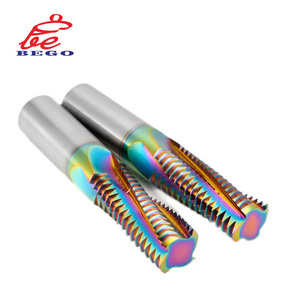

Coating:

-

TiAIN, ALTiSi+N

-

Place of Origin:

-

Shenzhen,China

-

Brand Name:

-

SAMHO

-

Model Number:

-

Thread Milling Cutter

-

Suitable for 1:

-

Alloy Steels,Prehardened Steels,Hardened Steels

-

Suitable for 2:

-

Carbon Steels,Copper,Titanium Alloys,Aluminum Alloys

-

Raw material:

-

Tungsten Steel

-

HRC:

-

65 Degrees

-

Usage:

-

CNC Machine Center

-

Flutes:

-

4 Flutes

-

MOQ:

-

5 Pieces

-

OEM:

-

Avaliable

-

Manufacture:

-

We are factory

-

Shipment:

-

DHL.TNT.UPS.FEDEX.EMS

Coating Characteristics

|

Coating Name

|

HG

|

HT

|

HB

|

HD

|

|

Ingredient

|

ALTiSi+N

|

ALTiSi+N

|

ALTiCR+N

|

NanoDiamond

|

|

Colour

|

Bronze

|

Bronze

|

Darkgrey

|

Darkgrey

|

|

Characteristics

|

Ultra high hardness,

super oxidation resistance,

high density.

|

Ultra high hardness,

super oxidation resistance,

high density.

|

Ultra low oxidation

low friction

|

Ultra high

wear resistance

|

|

Hardness

|

3700(HV)

|

3500(HV)

|

3500(HV)

|

10000(HV)

|

|

Coefficient of Friction

|

0.4

|

0.36

|

0.3

|

<0.1

|

|

Oxidation Onset Temperature

|

1300

|

1200

|

1100

|

600

|

|

Coating Thickness

|

2-4um

|

2-4um

|

2-4um

|

6-10um

|

Products Description

|

Model Number

|

Tooth Pitch

|

Diameter of Cut

|

Effective Length

|

Shank Diameter

|

Overall Length

|

Number of Flutes

|

Type

|

|||||||

|

HRC65 Full Tooth Thread Cutter(Metric Coarse Thread)

|

|

|

|

|

|

|

|

|||||||

|

M3*0.5

|

0.5

|

2.3

|

6

|

4

|

50

|

3

|

Full Teeth

|

|||||||

|

M3.5*0.6

|

0.6

|

2.7

|

7

|

4

|

50

|

3

|

Full Teeth

|

|||||||

|

M4*0.7

|

0.7

|

3

|

8

|

4

|

50

|

3

|

Full Teeth

|

|||||||

|

M4.5*0.75

|

0.75

|

3.4

|

9

|

4

|

50

|

3

|

Full Teeth

|

|||||||

|

M5*0.8

|

0.8

|

4

|

10

|

4

|

50

|

3

|

Full Teeth

|

|||||||

|

M6*1.0

|

1

|

4.8

|

12

|

6

|

60

|

3

|

Full Teeth

|

|||||||

|

M8*1.25

|

1.25

|

6

|

16

|

6

|

60

|

3

|

Full Teeth

|

|||||||

|

M10*1.5

|

1.5

|

8

|

20

|

8

|

60

|

3

|

Full Teeth

|

|||||||

|

M12*1.75

|

1.75

|

9.8

|

30

|

10

|

75

|

4

|

Full Teeth

|

|||||||

|

M14*2.0

|

2

|

10

|

30

|

10

|

75

|

4

|

Full Teeth

|

|||||||

|

M16*2.0

|

2

|

12

|

30

|

12

|

75

|

4

|

Full Teeth

|

|||||||

|

M18*2.5

|

2.5

|

14

|

36

|

14

|

80

|

4

|

Full Teeth

|

|||||||

|

HRC65 Full Tooth Thread Cutter(Metric Fine Thread)

|

|

|

|

|

|

|

|

|||||||

|

M6*0.5

|

0.5

|

4

|

10

|

4

|

50

|

3

|

Full Teeth

|

|||||||

|

M8*0.5

|

0.5

|

6

|

13

|

6

|

60

|

3

|

Full Teeth

|

|||||||

|

M6*0.75

|

0.75

|

4.8

|

12

|

6

|

60

|

3

|

Full Teeth

|

|||||||

|

M10*0.75

|

0.75

|

8

|

20

|

8

|

60

|

3

|

Full Teeth

|

|||||||

|

M8*1.0

|

1

|

6

|

16

|

6

|

55

|

3

|

Full Teeth

|

|||||||

|

M10*1.0

|

1

|

8

|

20

|

8

|

60

|

3

|

Full Teeth

|

|||||||

|

M12*1.0

|

1

|

10

|

22

|

10

|

75

|

4

|

Full Teeth

|

|||||||

|

M16*1.0

|

1

|

12

|

22

|

12

|

75

|

4

|

Full Teeth

|

|||||||

|

M20*1.0

|

1

|

16

|

30

|

16

|

90

|

4

|

Full Teeth

|

|||||||

|

M10*1.25

|

1.25

|

8

|

20

|

8

|

60

|

3

|

Full Teeth

|

|||||||

|

M12*1.25

|

1.25

|

10

|

25

|

10

|

75

|

4

|

Full Teeth

|

|||||||

|

M12*1.5

|

1.5

|

10

|

28

|

10

|

75

|

4

|

Full Teeth

|

|||||||

|

M14*1.5

|

1.5

|

12

|

28

|

12

|

75

|

4

|

Full Teeth

|

|||||||

|

M20*1.5

|

1.5

|

16

|

30

|

16

|

90

|

4

|

Full Teeth

|

|||||||

Why Choose Us

Exhibition

FAQ

1. Are you a manufacturer? Do you have your own factory?

We are a specialized manufacturer with more than 15 years experience in cutting tool industry.

2. Can you produce special tungsten carbide cutters?

Yes, we can. Since 2012, we have changed our main business from standard end mills to special tungsten carbide cutters. We can offer custom-made tools according to your drawings and samples.

3. Do you provide OEM/ODM service?

Yes.

4. How do you handle the defects?

In fact, we will check carefully the quality and quantity of the goods before delivery. If you find the unqualified goods, we will provide feasible suggestions or replacements after receiving your feedback and detailed complaint information (or pictures).

5. What is the delivery time?

Delivery can be arranged within 24 hours after payment for the products in stock. For custom-made items, it will take 7-10 days for production.

6. How to place order?

1. You can fill in the order information in our on-line inquiry system.

2. You can contact our sales via email/Skype/Whats App. We will respond as soon as possible after receiving your order.

7. What's your payment method?

T/T, Paypal, Alibaba.

8. How do you deliver the goods?

SF express, DHL, TNT, FEDEX, EMS, by air, by sea.

We are a specialized manufacturer with more than 15 years experience in cutting tool industry.

2. Can you produce special tungsten carbide cutters?

Yes, we can. Since 2012, we have changed our main business from standard end mills to special tungsten carbide cutters. We can offer custom-made tools according to your drawings and samples.

3. Do you provide OEM/ODM service?

Yes.

4. How do you handle the defects?

In fact, we will check carefully the quality and quantity of the goods before delivery. If you find the unqualified goods, we will provide feasible suggestions or replacements after receiving your feedback and detailed complaint information (or pictures).

5. What is the delivery time?

Delivery can be arranged within 24 hours after payment for the products in stock. For custom-made items, it will take 7-10 days for production.

6. How to place order?

1. You can fill in the order information in our on-line inquiry system.

2. You can contact our sales via email/Skype/Whats App. We will respond as soon as possible after receiving your order.

7. What's your payment method?

T/T, Paypal, Alibaba.

8. How do you deliver the goods?

SF express, DHL, TNT, FEDEX, EMS, by air, by sea.

Coating Characteristics

|

Coating Name

|

HG

|

HT

|

HB

|

HD

|

|

Ingredient

|

ALTiSi+N

|

ALTiSi+N

|

ALTiCR+N

|

NanoDiamond

|

|

Colour

|

Bronze

|

Bronze

|

Darkgrey

|

Darkgrey

|

|

Characteristics

|

Ultra high hardness,

super oxidation resistance,

high density.

|

Ultra high hardness,

super oxidation resistance,

high density.

|

Ultra low oxidation

low friction

|

Ultra high

wear resistance

|

|

Hardness

|

3700(HV)

|

3500(HV)

|

3500(HV)

|

10000(HV)

|

|

Coefficient of Friction

|

0.4

|

0.36

|

0.3

|

<0.1

|

|

Oxidation Onset Temperature

|

1300

|

1200

|

1100

|

600

|

|

Coating Thickness

|

2-4um

|

2-4um

|

2-4um

|

6-10um

|

Products Description

|

Model Number

|

Tooth Pitch

|

Diameter of Cut

|

Effective Length

|

Shank Diameter

|

Overall Length

|

Number of Flutes

|

Type

|

|||||||

|

HRC65 Full Tooth Thread Cutter(Metric Coarse Thread)

|

|

|

|

|

|

|

|

|||||||

|

M3*0.5

|

0.5

|

2.3

|

6

|

4

|

50

|

3

|

Full Teeth

|

|||||||

|

M3.5*0.6

|

0.6

|

2.7

|

7

|

4

|

50

|

3

|

Full Teeth

|

|||||||

|

M4*0.7

|

0.7

|

3

|

8

|

4

|

50

|

3

|

Full Teeth

|

|||||||

|

M4.5*0.75

|

0.75

|

3.4

|

9

|

4

|

50

|

3

|

Full Teeth

|

|||||||

|

M5*0.8

|

0.8

|

4

|

10

|

4

|

50

|

3

|

Full Teeth

|

|||||||

|

M6*1.0

|

1

|

4.8

|

12

|

6

|

60

|

3

|

Full Teeth

|

|||||||

|

M8*1.25

|

1.25

|

6

|

16

|

6

|

60

|

3

|

Full Teeth

|

|||||||

|

M10*1.5

|

1.5

|

8

|

20

|

8

|

60

|

3

|

Full Teeth

|

|||||||

|

M12*1.75

|

1.75

|

9.8

|

30

|

10

|

75

|

4

|

Full Teeth

|

|||||||

|

M14*2.0

|

2

|

10

|

30

|

10

|

75

|

4

|

Full Teeth

|

|||||||

|

M16*2.0

|

2

|

12

|

30

|

12

|

75

|

4

|

Full Teeth

|

|||||||

|

M18*2.5

|

2.5

|

14

|

36

|

14

|

80

|

4

|

Full Teeth

|

|||||||

|

HRC65 Full Tooth Thread Cutter(Metric Fine Thread)

|

|

|

|

|

|

|

|

|||||||

|

M6*0.5

|

0.5

|

4

|

10

|

4

|

50

|

3

|

Full Teeth

|

|||||||

|

M8*0.5

|

0.5

|

6

|

13

|

6

|

60

|

3

|

Full Teeth

|

|||||||

|

M6*0.75

|

0.75

|

4.8

|

12

|

6

|

60

|

3

|

Full Teeth

|

|||||||

|

M10*0.75

|

0.75

|

8

|

20

|

8

|

60

|

3

|

Full Teeth

|

|||||||

|

M8*1.0

|

1

|

6

|

16

|

6

|

55

|

3

|

Full Teeth

|

|||||||

|

M10*1.0

|

1

|

8

|

20

|

8

|

60

|

3

|

Full Teeth

|

|||||||

|

M12*1.0

|

1

|

10

|

22

|

10

|

75

|

4

|

Full Teeth

|

|||||||

|

M16*1.0

|

1

|

12

|

22

|

12

|

75

|

4

|

Full Teeth

|

|||||||

|

M20*1.0

|

1

|

16

|

30

|

16

|

90

|

4

|

Full Teeth

|

|||||||

|

M10*1.25

|

1.25

|

8

|

20

|

8

|

60

|

3

|

Full Teeth

|

|||||||

|

M12*1.25

|

1.25

|

10

|

25

|

10

|

75

|

4

|

Full Teeth

|

|||||||

|

M12*1.5

|

1.5

|

10

|

28

|

10

|

75

|

4

|

Full Teeth

|

|||||||

|

M14*1.5

|

1.5

|

12

|

28

|

12

|

75

|

4

|

Full Teeth

|

|||||||

|

M20*1.5

|

1.5

|

16

|

30

|

16

|

90

|

4

|

Full Teeth

|

|||||||

Why Choose Us

Exhibition

FAQ

1. Are you a manufacturer? Do you have your own factory?

We are a specialized manufacturer with more than 15 years experience in cutting tool industry.

2. Can you produce special tungsten carbide cutters?

Yes, we can. Since 2012, we have changed our main business from standard end mills to special tungsten carbide cutters. We can offer custom-made tools according to your drawings and samples.

3. Do you provide OEM/ODM service?

Yes.

4. How do you handle the defects?

In fact, we will check carefully the quality and quantity of the goods before delivery. If you find the unqualified goods, we will provide feasible suggestions or replacements after receiving your feedback and detailed complaint information (or pictures).

5. What is the delivery time?

Delivery can be arranged within 24 hours after payment for the products in stock. For custom-made items, it will take 7-10 days for production.

6. How to place order?

1. You can fill in the order information in our on-line inquiry system.

2. You can contact our sales via email/Skype/Whats App. We will respond as soon as possible after receiving your order.

7. What's your payment method?

T/T, Paypal, Alibaba.

8. How do you deliver the goods?

SF express, DHL, TNT, FEDEX, EMS, by air, by sea.

We are a specialized manufacturer with more than 15 years experience in cutting tool industry.

2. Can you produce special tungsten carbide cutters?

Yes, we can. Since 2012, we have changed our main business from standard end mills to special tungsten carbide cutters. We can offer custom-made tools according to your drawings and samples.

3. Do you provide OEM/ODM service?

Yes.

4. How do you handle the defects?

In fact, we will check carefully the quality and quantity of the goods before delivery. If you find the unqualified goods, we will provide feasible suggestions or replacements after receiving your feedback and detailed complaint information (or pictures).

5. What is the delivery time?

Delivery can be arranged within 24 hours after payment for the products in stock. For custom-made items, it will take 7-10 days for production.

6. How to place order?

1. You can fill in the order information in our on-line inquiry system.

2. You can contact our sales via email/Skype/Whats App. We will respond as soon as possible after receiving your order.

7. What's your payment method?

T/T, Paypal, Alibaba.

8. How do you deliver the goods?

SF express, DHL, TNT, FEDEX, EMS, by air, by sea.

Hot Searches