- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Jopar

-

Voltage:

-

380/415/420/440

-

Power:

-

18.5kw*18.5kw

-

Dimension(L*W*H):

-

26*1.5M

-

Weight:

-

7.5 kg

-

Diameter:

-

50-114mm

-

Thickness:

-

0.5-3.0mm

-

Horizontal shaft:

-

60mm

-

Vertical shaft:

-

40mm

-

Welding type:

-

Argon welding

-

Cutting Type:

-

Metal saw cutting

-

Material of stand:

-

Casting Iron

-

Function:

-

Metal Processing

-

Pipe Length:

-

3-6m

-

Market:

-

India Russia Ect

-

Certification:

-

ISO9001:2015

Quick Details

-

Pipe Material:

-

Carbon steel

-

Production Capacity:

-

0-10m/min

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Jopar

-

Voltage:

-

380/415/420/440

-

Power:

-

18.5kw*18.5kw

-

Dimension(L*W*H):

-

26*1.5M

-

Weight:

-

7.5 kg

-

Diameter:

-

50-114mm

-

Thickness:

-

0.5-3.0mm

-

Horizontal shaft:

-

60mm

-

Vertical shaft:

-

40mm

-

Welding type:

-

Argon welding

-

Cutting Type:

-

Metal saw cutting

-

Material of stand:

-

Casting Iron

-

Function:

-

Metal Processing

-

Pipe Length:

-

3-6m

-

Market:

-

India Russia Ect

-

Certification:

-

ISO9001:2015

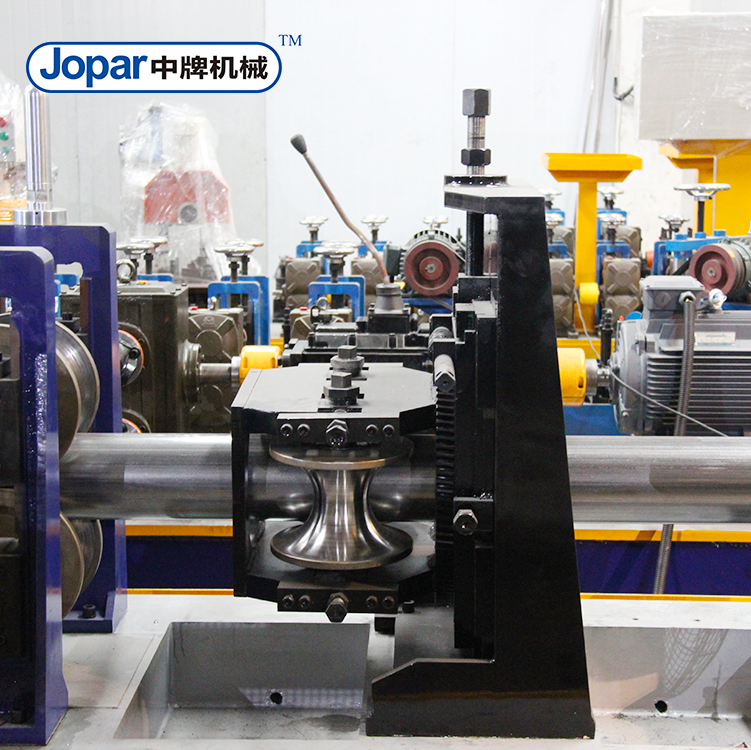

| Model | Horizontal shaft O.D | Vertical shaft O.D. | Tube Range | Thickness | Drive Motor | Dimension |

| ZP-S40 | 40mm | 30mm | ∅8-51mm | 0.3-2.2mm |

Front:7.5kw Fear: 7.5kw |

21.5m*1.2m |

| ZP-S50 | 50mm | 30mm | ∅25-76mm | 0.4-2.5mm |

Front:11kw Fear: 11kw |

24m*1.3m |

| ZP-S60 | 60mm | 40mm | ∅50-114mm | 0.5-3.0mm |

Front:15kw Fear:15 kw |

26m*1.5m |

| ZP-S80 | 80mm | 50mm | ∅89-168mm | 0.8-4.0mm |

Front:18.5kw Fear:18.5 kw |

32m*2.5m |

| ZP-S100 | 100mm | 60mm | ∅114-219mm | 1.0-6.0mm |

Front:22kw Fear: 22kw |

36m*2.8m |

| ZP-S120 | 120mm | 80mm | ∅168-325mm | 1.5-8.0mm |

Front:37kw Fear: 37kw |

40m*3.0m |

| Support For Customizing Orders | ||||||

Stronger p ipe making machine

This machine is mainly used for the production of stainless steel/carbon steel pipes/tubes with heavy thickness which applied in decoration,furniture,hand rail,outdoor decoration,household appliances industry,steel pipes/tubes etc.(round tubes,square tubes,rectangle rubes).

The Process flow:

Single/Double S ide U ncoiler—Strip Jointing — 3 Roller leeling-Tube Making Machine (1.Forming Part,2.Welding Part,3. S izing Part)—Cooling System- Outside Weld B ead G rinder—Automatic C utting S ystem—Run O ut T able—Electric C ontrol S ystem—Rolls Sets /Die Sets .