- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380

-

Power:

-

120kw

-

Weight:

-

120000 kg

-

Material:

-

Pvc Gypsum

-

Usage:

-

Partition System

Quick Details

-

Production Capacity:

-

12

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

df

-

Voltage:

-

380

-

Power:

-

120kw

-

Weight:

-

120000 kg

-

Material:

-

Pvc Gypsum

-

Usage:

-

Partition System

1-10 million square meters plasterboard making machine line

M ain S pecifications

|

Length |

1800,2100,2400,2700,3000,3300,3600 |

|

Width |

900,1200 |

|

Thickness |

9.5,12.0,15.0,18.0,21.0,25.0 , 12.7 , 15.9 |

|

Note:According to user requirements, can produce other specifications of the plate |

|

The

Application

the gypsum board is often used in the Ceiling decoration. It is also a very good light walling material. In foreign countries, it is often used as walling material more than ceiling.

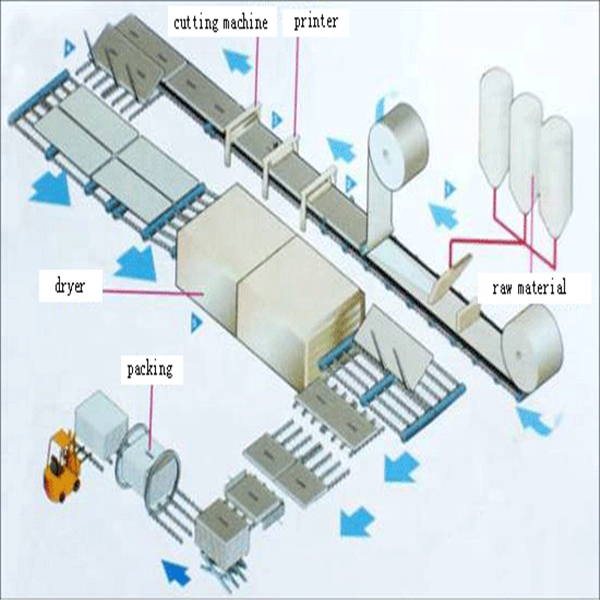

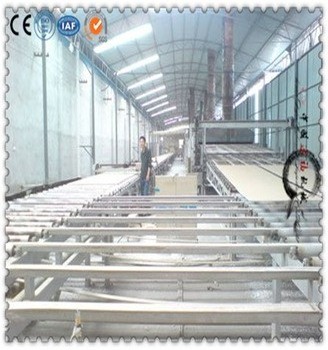

Production process mainly includes the following several aspects

paper supply system,water supply system,starch supply system,vesical supply system,forming section,transpotation system,transferring system,heat supply system,drying system board releasing system,dust collecting system,electricity -control system

The gypsum board process is as following:

Plaster hopper---mixing---shaping---freezing---first cutting---drying

---detailed cutting---packing---finished products

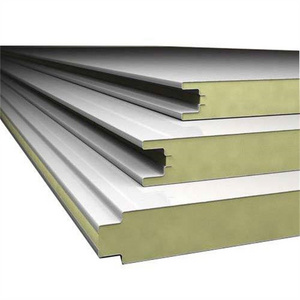

Main Features

1) low energy consumption, High Productivity.

2) Lightness. Thermal Insulation

3) Fire proof, Sound insulation performance,Decoration performance

4) Save Space

5) Full Automatic

Little investment, high reward and little period.

Engnieer guiding

High quality

waterproof, fireproof, sound proof

Why choose us!

Manufacturer&Reasonable price√

We have our own factory with efficient mature production system

experienced &professional √

we have more than 20years history! Our team consists of qualified Engineers, Sourcing professionals, Operations professionals, and a select group of premium vendors here

excellent quality√

we ensure every production should be safe and have good operation.

Best after-service√

Our experienced engineers are ready to provide you with pre-sales post-sales technical support

Contact us

If you are interested in our products and want to get more information, please connect with me. You can chat with me online or send me an inquiry.I will give my best service http://dafumachinery.en.alibaba.com/