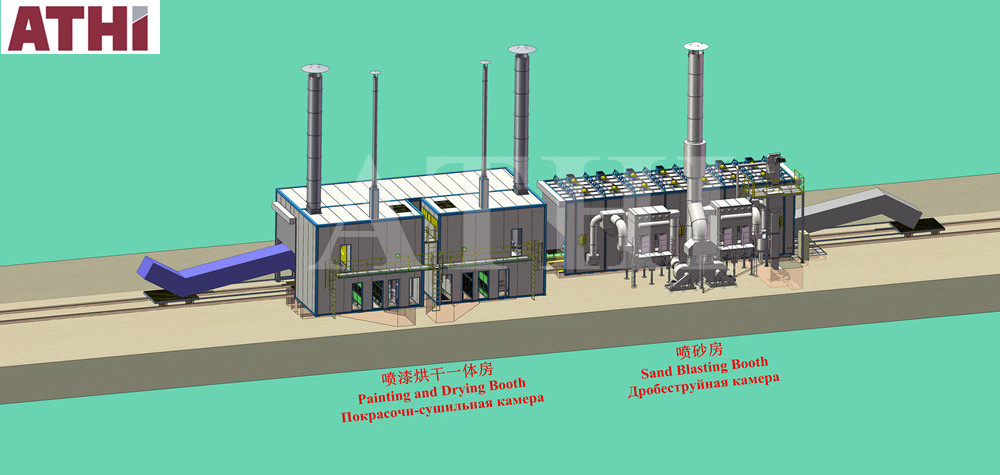

Our factory provides quality, durable coatings for iron or aluminium in a wide variety of colors and finishes. Our ovens fit large and long items.

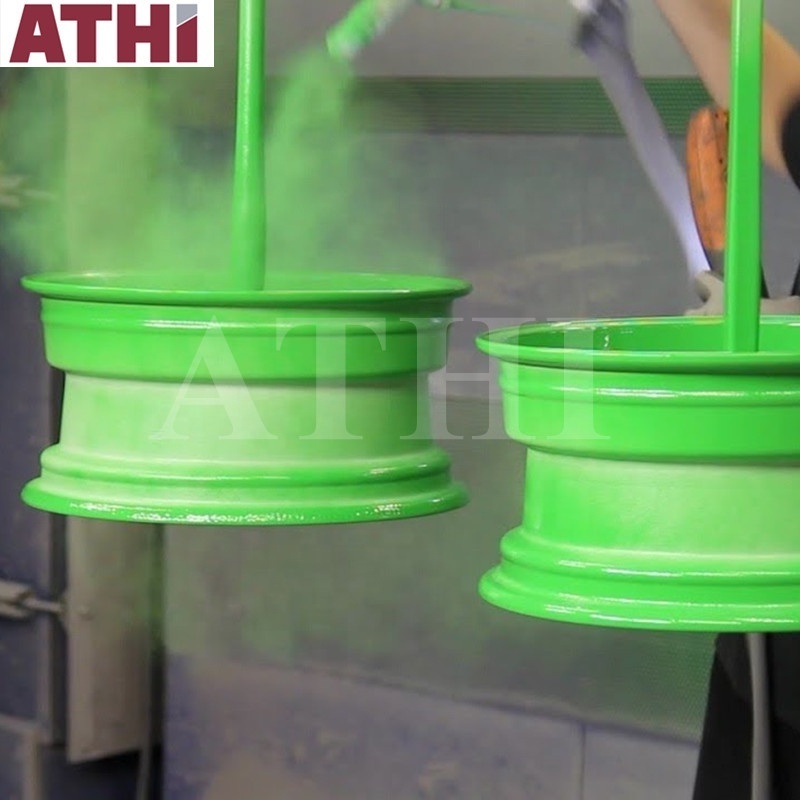

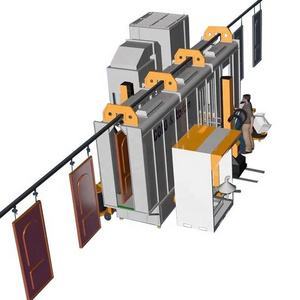

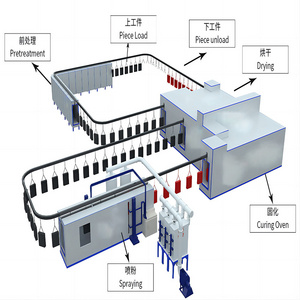

Powder Coating can restore your metal assets with a new finish. The Powder Coating process system can coat metal. For example we can coat metal file cabinets, shelving storage, cabinets, desks, lockers, elevator doors, mail boxes, gates, car rims, bike frames, railings, iron fencing & truck parts.

We keep peace with environmental technology, we donot use solvents on any product.

Powder coating can be used for a wide array of metal and non-metal surfaces. Powder coating is an eco-friendly alternative to liquid paint and high VOC chemical paint solutions.

Powder coating helps in reduction of air pollution. It also helps reduce health hazards to the operators.

Powder Coating can restore your metal assets with a new finish. The Powder Coating process system can coat metal. For example we can coat metal file cabinets, shelving storage, cabinets, desks, lockers, elevator doors, mail boxes, gates, car rims, bike frames, railings, iron fencing & truck parts.

We keep peace with environmental technology, we donot use solvents on any product.

Powder coating can be used for a wide array of metal and non-metal surfaces. Powder coating is an eco-friendly alternative to liquid paint and high VOC chemical paint solutions.

Powder coating helps in reduction of air pollution. It also helps reduce health hazards to the operators.