- Product Details

- {{item.text}}

Quick Details

-

Positioning Accuracy (mm):

-

0.02 mm

-

Travel (X Axis)(mm):

-

1300 mm

-

Travel (Y Axis)(mm):

-

2500 mm

-

Repeatability (X/Y/Z) (mm):

-

0.02 mm

-

Spindle Motor Power(kW):

-

3.2kw

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Mingshi

-

Voltage:

-

220v/380v

-

Dimension(L*W*H):

-

2200*2200*1300mm

-

Power (kW):

-

3.7

-

Weight (KG):

-

1000

-

Control system:

-

DSP A11 Control System

-

Transmission:

-

Gear Rack

-

Table Surface:

-

T-slot Aluminum +PVC

-

Software:

-

Ucancam / ArtCam/TYPE3

-

Motor and driver:

-

Leashine Stepper Motor Driver

-

Guide rail:

-

Taiwan Hiwin Square Guide Rail

-

Product name:

-

Woodworking Cnc Router Machine

-

Application:

-

Wood Working Cnc Router

-

Keywords:

-

CNC Woodworking Router

-

Function:

-

Wood Acylic Plywood MDF Engraving

Quick Details

-

Working Table Size(mm):

-

1300×2500

-

Machine Type:

-

CNC Router

-

Range of Spindle Speed(r.p.m):

-

1 - 24000 rpm

-

Positioning Accuracy (mm):

-

0.02 mm

-

Travel (X Axis)(mm):

-

1300 mm

-

Travel (Y Axis)(mm):

-

2500 mm

-

Repeatability (X/Y/Z) (mm):

-

0.02 mm

-

Spindle Motor Power(kW):

-

3.2kw

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Mingshi

-

Voltage:

-

220v/380v

-

Dimension(L*W*H):

-

2200*2200*1300mm

-

Power (kW):

-

3.7

-

Weight (KG):

-

1000

-

Control system:

-

DSP A11 Control System

-

Transmission:

-

Gear Rack

-

Table Surface:

-

T-slot Aluminum +PVC

-

Software:

-

Ucancam / ArtCam/TYPE3

-

Motor and driver:

-

Leashine Stepper Motor Driver

-

Guide rail:

-

Taiwan Hiwin Square Guide Rail

-

Product name:

-

Woodworking Cnc Router Machine

-

Application:

-

Wood Working Cnc Router

-

Keywords:

-

CNC Woodworking Router

-

Function:

-

Wood Acylic Plywood MDF Engraving

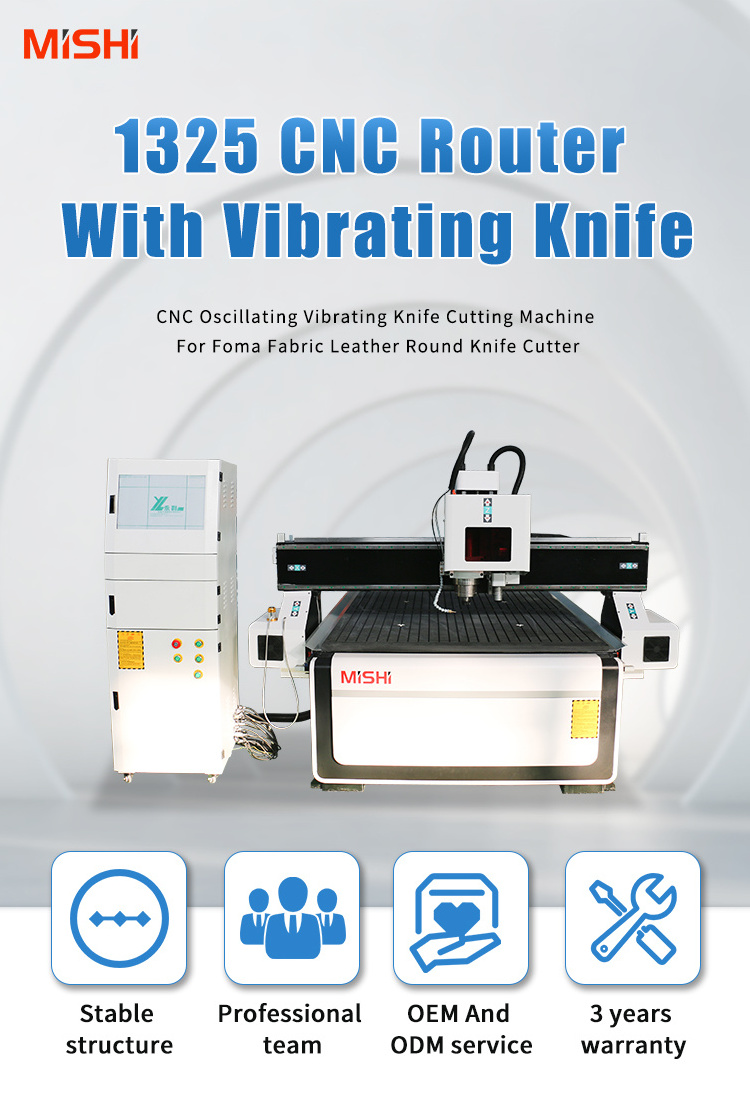

Technical Parameters

|

Machine Model

|

1325 CNC Router With Vibrating Knife

|

|

XYZ working area

|

1300*2500*200mm, 4*8ft

|

|

Optional working area |

1500*3000*200mm, 5*10ft

|

|

|

2000*3000*200mm, 6*10ft

|

|

|

2000*4000*200mm, 6*13ft

|

|

|

2000*6000*200mm, 6*20ft

|

|

Structure

|

High temperature tempering without deformation

|

|

Spindle power

|

5.5KW water cooling spindle

|

|

NO. of revolution

|

24000rpm/min

|

|

Spindle cooling

|

Water chiller

|

|

Control system

|

New Multidimensional Control System

|

|

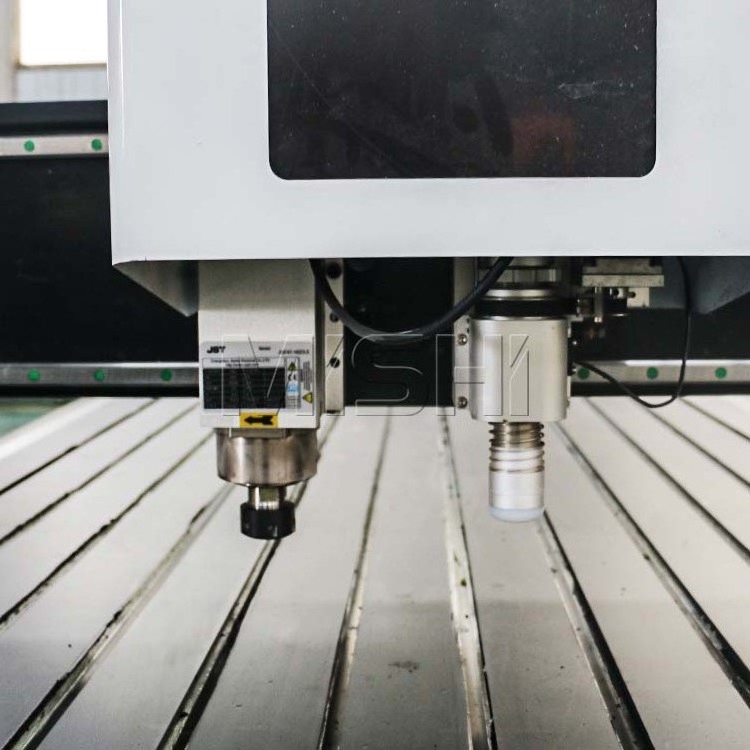

Oscillating knife

|

Multifunctional oscillating cutting module

|

|

Drive system

|

Servo motors & drives

|

|

Transmission

|

XY axis grinding rack, Z axis ball screw

|

|

Reduction gear

|

High precision planetary reducer

|

|

Guide Rail

|

Original TAIWAN HIWIN imported guide rail

|

|

Max. moving speed

|

30000mm/min

|

|

Max. cutting speed

|

20000mm/min

|

|

Working table

|

5 zones regional vacuum adsorption

|

|

Vacuum pump

|

water or air vacuum pump

|

|

Lubrication system

|

Automatic oil injection

|

|

Working voltage

|

AC380V/50HZ

|

Detailed Images

Oscillating Knife cutting has the advantages of small cutting force, low cutting heat, the high surface qu-ality of the work piece, easy chip handling, improved tool durability, stable processing, and high producti-on efficiency.

Features:

1. Cutting by knife no air pollution, no burnt edge, cutting speed is 5-8 times faster than laser machine

2. Imported square linear guide and Japan servo motor ensure high precision and fast cutting speed.

3. Installed with Ethernet port which is a more convenient operation.

4. very easy to operate with one button to switch/shift between knife & spindle.

5. A special safety sensing device meets the European standard.

6. It can be flexibly equipped with different cutting tools to meet a variety of needs.

7.including all function of standard CNC router, and vibrating knife cutting machine.

8.Break point continuous engraving function: When a power failure or other unexpected condition caus-es the machine to stop, restart the machine, it will start processing from the break point

9.Emergency stop switch: If machine have error, running fast, emergency touch people, the machine will stop, it is very convenient, you press again machine will start to work. Just like our machine have Triple protection switch.

10. No consumption parts except for the cutter blades.while the laser machine needs to change consu-mption tubes.

2. Imported square linear guide and Japan servo motor ensure high precision and fast cutting speed.

3. Installed with Ethernet port which is a more convenient operation.

4. very easy to operate with one button to switch/shift between knife & spindle.

5. A special safety sensing device meets the European standard.

6. It can be flexibly equipped with different cutting tools to meet a variety of needs.

7.including all function of standard CNC router, and vibrating knife cutting machine.

8.Break point continuous engraving function: When a power failure or other unexpected condition caus-es the machine to stop, restart the machine, it will start processing from the break point

9.Emergency stop switch: If machine have error, running fast, emergency touch people, the machine will stop, it is very convenient, you press again machine will start to work. Just like our machine have Triple protection switch.

10. No consumption parts except for the cutter blades.while the laser machine needs to change consu-mption tubes.

Application

Application

1. Wood industry: wood furniture making, 3d wood relief carving, wooden craftwork production Speakers, game console cabinets, computer tables, sewing machine tables, etc.

2. Advertising products industry: 3D letter sign making, acrylic cutting, and engraving.

3. Board processing industry: insulation piece, acrylic board, plastic chemical products, PCB, compact grade laminate, ABS, PP, PE, and other cementitious mixtures milling process.

4. Decoration industry: folding screens, wave plates, advertising boards, sign making, and logo processing.

5. Arts & Crafts industries: Engrave on artificial stones, woods, bamboo, and marbles.

6. Processing material: engraving, milling, and cutting processing for acrylic, PVC, artificial stones plastics and soft metal sheets, and so on.

7. The oscillating knife is used for cutting flexible material PVC, KT board, thick foam, aluminum-plastic composite panel, polypropylene hollow sheets, foot pads, and leather.acrylic

2. Advertising products industry: 3D letter sign making, acrylic cutting, and engraving.

3. Board processing industry: insulation piece, acrylic board, plastic chemical products, PCB, compact grade laminate, ABS, PP, PE, and other cementitious mixtures milling process.

4. Decoration industry: folding screens, wave plates, advertising boards, sign making, and logo processing.

5. Arts & Crafts industries: Engrave on artificial stones, woods, bamboo, and marbles.

6. Processing material: engraving, milling, and cutting processing for acrylic, PVC, artificial stones plastics and soft metal sheets, and so on.

7. The oscillating knife is used for cutting flexible material PVC, KT board, thick foam, aluminum-plastic composite panel, polypropylene hollow sheets, foot pads, and leather.acrylic

After sales service

We have professional pre-sales and after sales service Mingshi CNC team

1. 24/7 online service .

2. 3 years warranty for machine.

3. After sale office in differ country

4. Free spare parts with shipping.

5. Free online technical support and install train.

2. 3 years warranty for machine.

3. After sale office in differ country

4. Free spare parts with shipping.

5. Free online technical support and install train.

Shipping and Packing

Packaging Details

1. Outside package: Standard export plywood case for CNC Router for advertising.

2. Inner package: Stretch film and plastic film for humidity.

Port

Qingdao/Shanghai/Yiwu/Dalian/Guangzhou/Tianjin/Shenzhen

Company Introduction

FAQ

Q: How to install and maintain the machine?

A: Before you use it, we will send the operation tutorial and installation operation video with an English version to you. If you still can not operate, we will provide video guidance online.

Q: What are the machine working environment requirements?

A: The machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

Q: How many days do the goods ready to ship?

A: The specific delivery date needs to be communicated with the sales. If we have stock, it can be shipped within five days. If it is not in stock, it will take 15 to 20 days to prepare goods. By the way, Most of the machines are in stock.

Q: What is the mode of transportation of the products?

A: The specific transportation method can be selected according to the needs, like by sea, by air, or by train. Our trade terms are mostly centered on FOB, but we offer EXW, CIF, depending on which is more convenient for you.

Please feel free to send us an inquiry or message to know more about the machine.

We specialize in CNC routers and laser machines for 12 years

The response will be within 1 minute during working time, And within 6 hours during off duty time.

We specialize in CNC routers and laser machines for 12 years

The response will be within 1 minute during working time, And within 6 hours during off duty time.

you haven't found the machine you need, don't hesitate to contact us too.

We will do our best to give you the best suggestion.

We can also supply products related to our machines

Hot Searches