- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

NWP

-

Power (kW):

-

7.5

-

Weight (KG):

-

2200

-

Product name:

-

Steel Pipe Bending Machine

-

Advantage:

-

High-accuracy

-

Max bending diameter:

-

50mm

-

Max bending radius:

-

R330

-

Min bending radius:

-

R20

-

Max bending angle:

-

190°

-

Max wall thickness:

-

2mm

-

Max feeding length:

-

2000mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

After-sell service:

-

Life time service

Quick Details

-

Bending Radius (mm):

-

10 - 250

-

Max. Bending Angle (Deg):

-

190

-

Bending Precision (Deg):

-

±0.1

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

NWP

-

Power (kW):

-

7.5

-

Weight (KG):

-

2200

-

Product name:

-

Steel Pipe Bending Machine

-

Advantage:

-

High-accuracy

-

Max bending diameter:

-

50mm

-

Max bending radius:

-

R330

-

Min bending radius:

-

R20

-

Max bending angle:

-

190°

-

Max wall thickness:

-

2mm

-

Max feeding length:

-

2000mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

After-sell service:

-

Life time service

Products Description

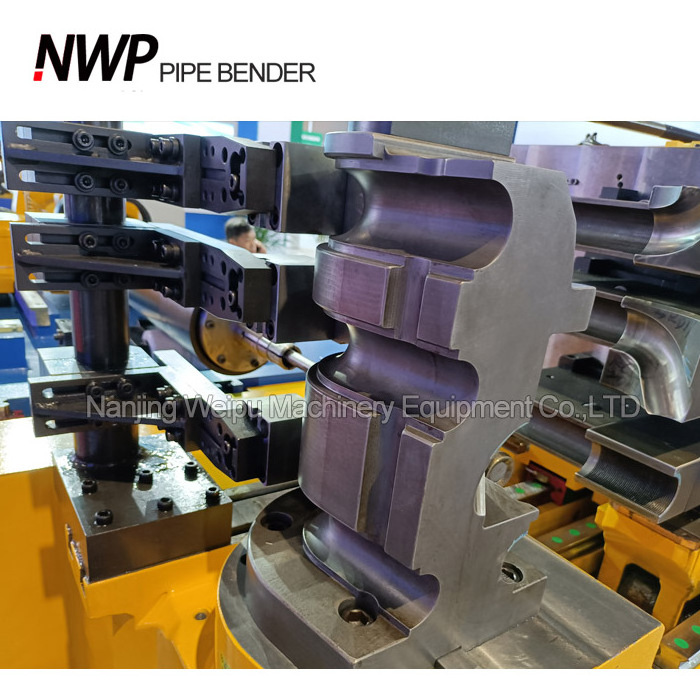

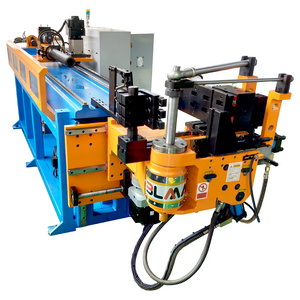

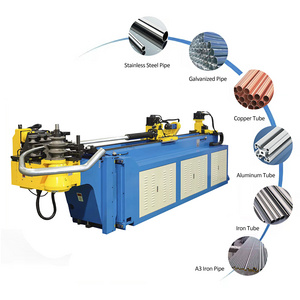

The hydraulic auto pipe bending machine is a versatile pipe bender, which can realize the multi-angle bending of the pipe and achieve the desired effect. The automatic pipe bending machine is suitable for round pipes and square pipes by changing different size molds. This also makes it very popular in the sheet metal market.

The hydraulic auto pipe bending machine is driven by a servo motor to feed the material, and the positioning accuracy error is ±0.1, which meets the production requirements. The computer controls the operation of the whole machine, and the operation is convenient.

1. The pipe bending adopts CNC touch screen, the program setting is simple and easy to operate;

2. The body structure is stable and not easy to deform;

3. With slow positioning function, the bending angle is stable, and the repeatability is up to ±0.1°;

4. The error message is displayed on the screen to help the operator eliminate it immediately.

|

Model

|

Unit

|

50CNC-2A-1S

|

|

|

Max bending pipe diameter * wall thickness

|

mm

|

¢50.8 (2”)×2

|

|

|

Max bending radius

|

mm

|

R330

|

|

|

Min bending radius

|

mm

|

R20

|

|

|

Max bending angle

|

°

|

190

|

|

|

Max feeding length

|

mm

|

2500 (can be customized)

|

|

|

Feeding method

|

~

|

Direct delivery

|

|

|

Working speed (bending speed)

|

s

|

8°/s

|

|

|

Turning speed

|

s

|

180°/s

|

|

|

Bending accuracy

|

°

|

±0.1

|

|

|

Rotary accuracy

|

°

|

±0.1

|

|

|

Feeding accuracy

|

mm

|

±0.1

|

|

|

Data input method

|

~

|

Y.B.C

|

|

|

Rotating pipe servo motor power

|

kw

|

0.45

|

|

|

Feeding servo motor power

|

kw

|

1

|

|

|

Maximum allowable number of elbows

|

pcs

|

32

|

|

|

Oil motor power

|

kw

|

7.5

|

|

|

Max system pressure

|

MPa

|

12

|

|

|

Size

|

mm

|

4300*840*1300

|

|

|

Weight

|

kg

|

2200

|

|

|

Other

|

Support customization

|

|

|

Product Display

Details Images

Hot Searches