- Product Details

- {{item.text}}

Quick Details

-

Applicable Industries:

-

ALL

-

Marketing Type:

-

New Product 2022, New Product

-

After Warranty Service:

-

Video technical support

Quick Details

-

Place of Origin:

-

Jiangsu, China, Jiangsu, China

-

Brand Name:

-

QLTY

-

Weight (KG):

-

1, 1

-

Applicable Industries:

-

ALL

-

Marketing Type:

-

New Product 2022, New Product

-

After Warranty Service:

-

Video technical support

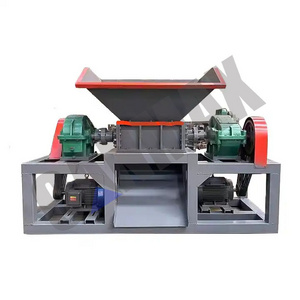

Products Show

Product Description

Applications:

Double shaft shredder knives blade is used shred for Packing materials, Metal sprues and housings, Aluminum profiles, Metal drums,

Electronic Scrap, Electrical devices, Household devices, Tires, Paper waste, Plastic Scrap, Refrigerators, and many more

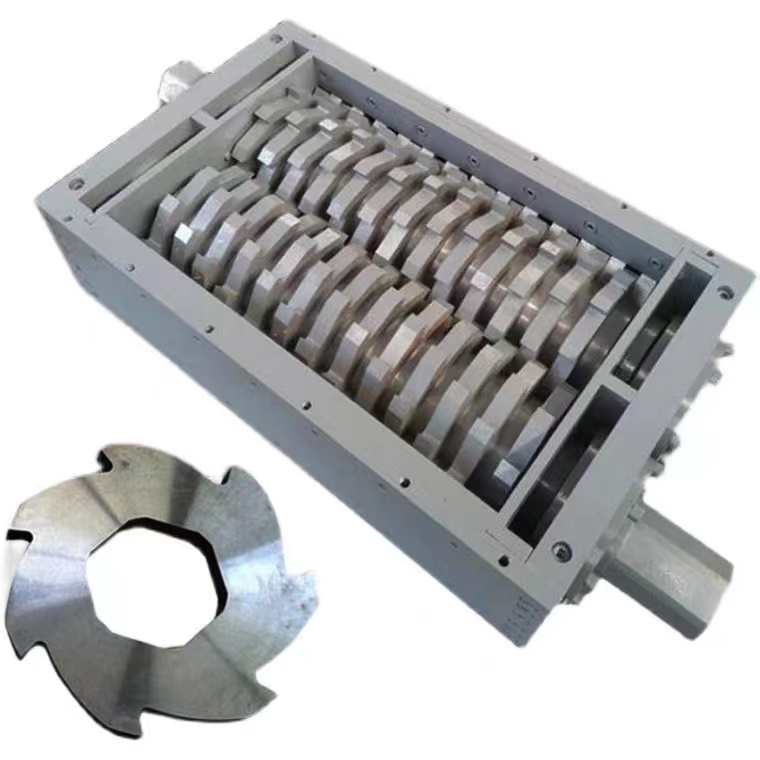

Description:

Double shaft shredder blade is one of the important parts of the shredder. The quality and correct installation of the blade

largely determine the use effect and life of the shredder. Generally, the spiral mounting method is adopted, and the spacer sleeve

is separated in the middle. The thickness of the blade should be 0.2 to 0.3 thick to prevent the blade from colliding during

operation and choose a reasonable thickness and number of teeth according to the size of the product.

With the development and innovation of the blade industry, the quality of the raw materials of the blade is increasing. The

shredder blades are commonly used in a variety of materials, and the materials are generally selected according to different

processing objects:

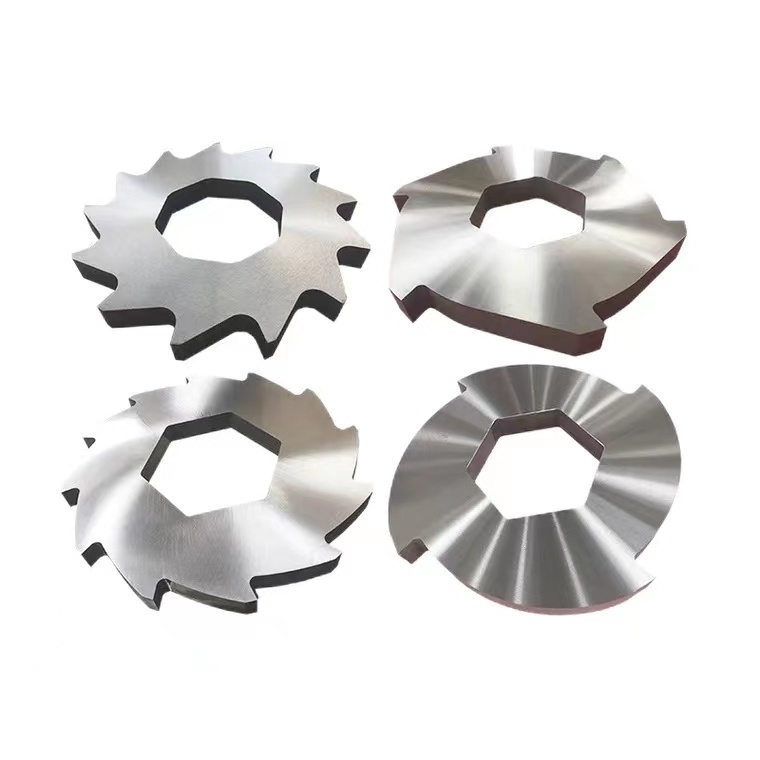

Common materials used in the plastic industry are 42CrMo, W5SiCr, SKD-11;

Common materials used in the metal industry are: 6CrW2Si, Cr12Mov, LD, H13;

Common materials used in the wood industry are: 5WSiCr, 6CrW2Si, SKH, SKD-11, D2;

The heat treatment reached HRC 55-57.

According to the material of the shredder shredded product, choose the appropriate blade. For rubber, the shredding of the film

generally adopts the blade of Cr12mov. For the shredding of wood and plastic, the blade of 55sicr is generally used, shredded

scrap, popped flower and flower iron. A blade using H13 is suitable because H13 is a hot work die steel which is a steel formed by

adding alloying elements to carbon steel. It has good comprehensive performance at medium temperature, high hardenability and low

heat treatment deformation rate, high-temperature resistance, and low deformation. Therefore, it is more suitable for shredding

metal products.

Commonly used twin-shaft shredder blades. The inner hole is generally an inner hexagon, and the outer circumference commonly has

three claws, six claws, eight claws, and twelve claws. The number of jaws, the clearance and the distance from the blade to the

spacer determine the size of the shredded material. Generally, the shredder blades are available in diameters from 200mm to 500mm

and thicknesses from 20mm to 55mm. They can also be customized according to customer needs.

Product Paramenters

|

Product Name

|

Dual Shaft Shredder Blades

|

|

Material

|

D2, SKD11,Cr12Mov...

|

|

Hardness

|

HRC56-58 according to customers request.

|

|

Treatment

|

Triple tempered , heat treatment

|

|

Performance

|

Wear resistance, high intensity,high toughness

|

|

Usefulness

|

electrical equipment, household equipment, tires, , plastic waste...

|

technical parameter

Hot Searches