- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

yudun

-

Name:

-

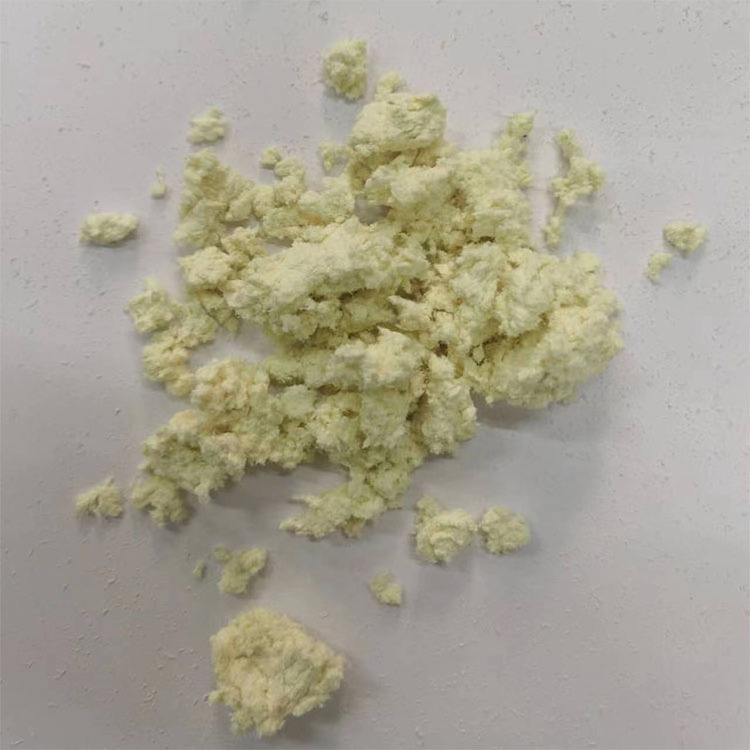

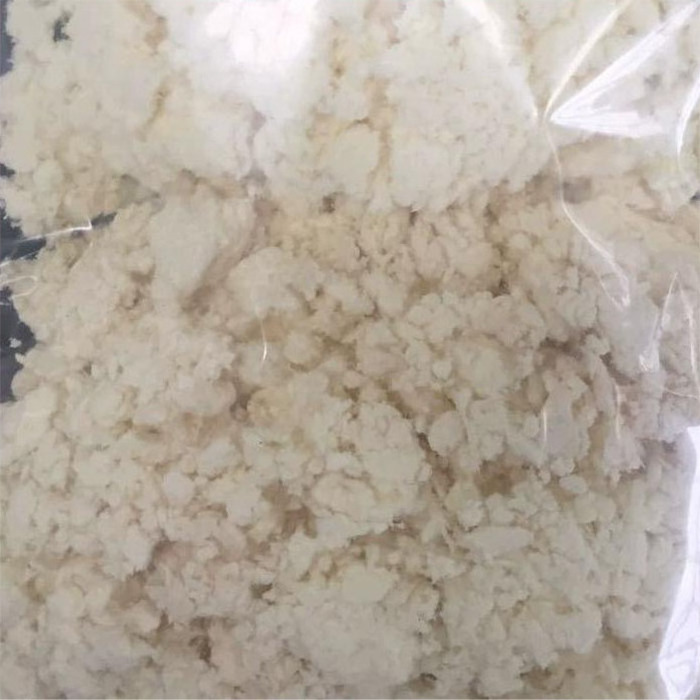

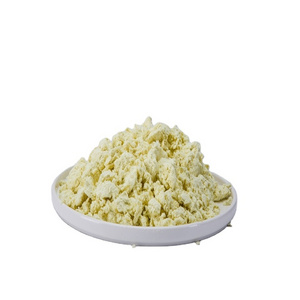

para aramid pulp

-

Shape:

-

short-cut fiber

-

Color:

-

light Yellow

-

Application:

-

Brake Pad

-

MOQ:

-

200kg

-

fiber length:

-

1.2-1.7mm

-

specific surface area:

-

5-12 m2/g

-

density:

-

1.44g/cm2

Quick Details

-

Feature:

-

Heat-Resistant

-

Fiber Length:

-

1.4-1.7mm

-

Fineness:

-

600

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

yudun

-

Name:

-

para aramid pulp

-

Shape:

-

short-cut fiber

-

Color:

-

light Yellow

-

Application:

-

Brake Pad

-

MOQ:

-

200kg

-

fiber length:

-

1.2-1.7mm

-

specific surface area:

-

5-12 m2/g

-

density:

-

1.44g/cm2

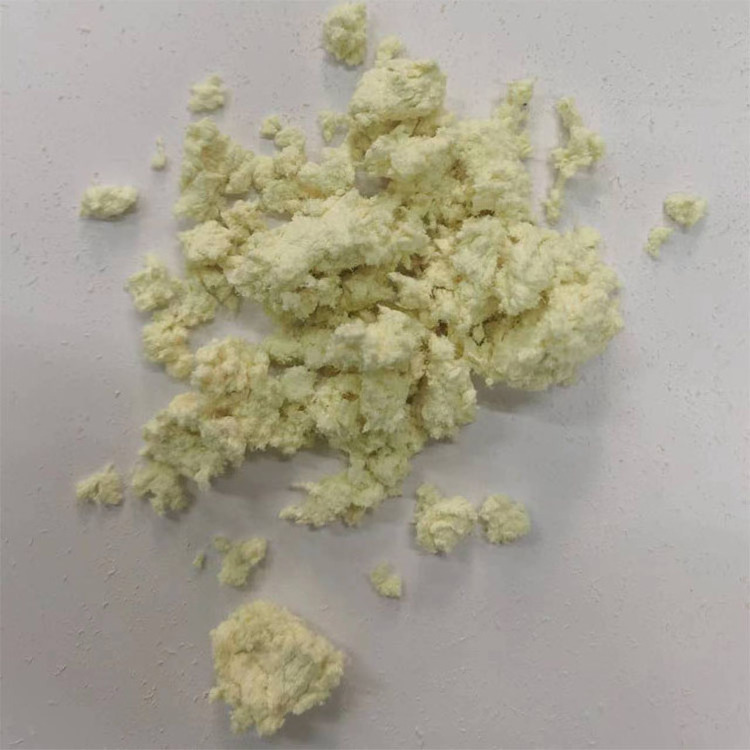

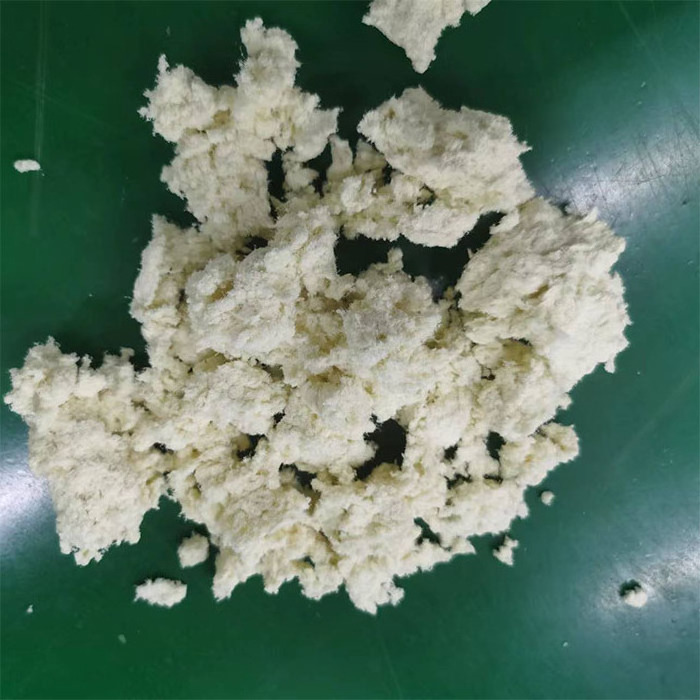

Para-aramid Pulp For Industrial friction

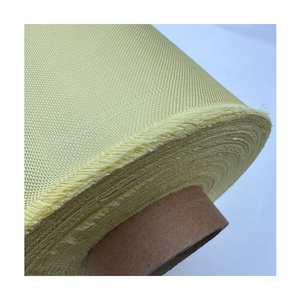

Aramid pulp is obtained after surface fibrillation treatment of aramid fibers. Its unique surface structure greatly improves the adhesion of the mixture, so it is very suitable as a reinforcing fiber for use in friction and sealing products.

The difference between aramid pulp and aramid fiber

1. Definition of aramid pulp

Aramid pulp is a chemical fiber raw material with good flame retardant properties, chemical corrosion resistance and excellent mechanical properties. It is a polymer material polymerized from aromatic polymers. It has an extremely high melting point and glass transition temperature and can be used stably for a long time at high temperatures.

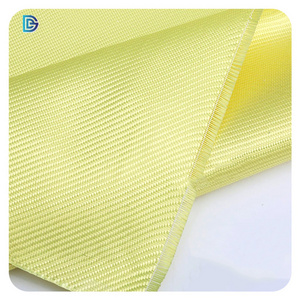

2. Definition of aramid fiber

Aramid fiber is a synthetic fiber processed from aramid pulp. It has high strength, high modulus, excellent fatigue and heat resistance, and can withstand harsh environments such as extreme high temperature, high pressure, strong acid, and strong alkali, long-term use.

3. The difference between aramid pulp and aramid fiber mainly lies in the use and processing method. Aramid pulp is a chemical fiber raw material and is mainly used to produce aramid fiber, engineering plastics, heat-resistant coatings, packaging materials, etc. Aramid fiber is a synthetic fiber processed from aramid pulp and can be used to make various high-strength, high-temperature, and corrosion-resistant textiles, industrial sewing threads, filter materials, etc. In addition, aramid pulp has a large particle size and usually needs to be processed into aramid fibers after high temperature and high pressure molding. Aramid fibers can be directly made into the required fabrics or other products.

mainly application:

specially for frication and sealing industry.

technical parameters:

|

commodity |

Aramid pulp |

|

Density |

1.44g/cm2 |

|

Fiber length |

1.2-1.7mm |

|

Specific surface area |

5-12 m2/g |

|

Additive content |

0.3-0.7% |

|

Moisture content |

5-7% |

|

colour |

yellow |

ARAMID PULP (501001) (FOR MANUFACTURING OF BRAKE PADS

1. who are we?

We are based in Jiangsu, China, start from 20 09 , supplying experience to high reputation in Europe, America, the Middle East, Africa, and Southeast Asia .

2. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD, CNY

Accepted Payment Type: T/T, L/C, MoneyGram,Credit Card,PayPal,Western Union;

Language Spoken:English, mandarin.