- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110V/220V/380V/others

-

Power (kW):

-

8

-

Weight (KG):

-

50 KG

-

Product Name:

-

Small portable Polyurea PU spray machine

-

Application:

-

construction spray

-

Keywords:

-

Pu foam and polyurea spray machine

-

Usage:

-

Spray Pu and polyurea

-

Function:

-

Insulation;Soundproofing;Water proof

-

Raw material:

-

steel

-

Finished products:

-

Yes

-

Applicable materials:

-

Two Component Polyurethane Foam & Polyurea

-

Advantage:

-

Easy to use and save material

-

Main Products:

-

Polyurea PU spray machine;Applicable raw materials

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GRAKO

-

Machine Type:

-

Spraying machine

-

Voltage:

-

110V/220V/380V/others

-

Power (kW):

-

8

-

Weight (KG):

-

50 KG

-

Product Name:

-

Small portable Polyurea PU spray machine

-

Application:

-

construction spray

-

Keywords:

-

Pu foam and polyurea spray machine

-

Usage:

-

Spray Pu and polyurea

-

Function:

-

Insulation;Soundproofing;Water proof

-

Raw material:

-

steel

-

Finished products:

-

Yes

-

Applicable materials:

-

Two Component Polyurethane Foam & Polyurea

-

Advantage:

-

Easy to use and save material

-

Main Products:

-

Polyurea PU spray machine;Applicable raw materials

Product Description

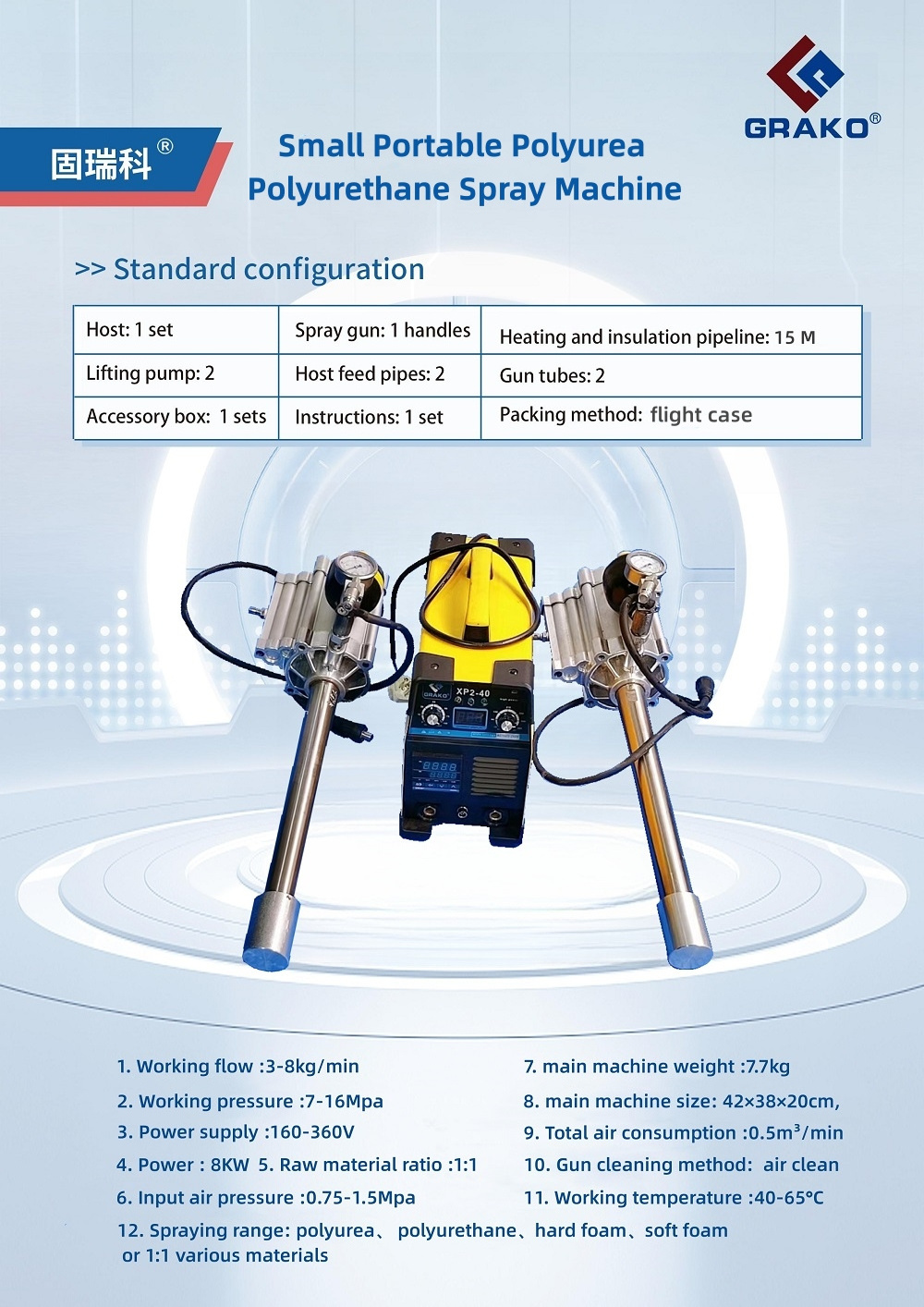

Small portable polyurea polyurethane spray machine

Standard Configuration

|

Host: 1 set

|

Spray gun: 1

|

Heating and insulation pipeline: 15m

|

|

Lifting pump: 2

|

Host feed pipes: 2

|

Gun tubes: 2

|

|

Accessory box: 1 sets

|

Instructions: 1 set

|

Packing method: flight case

|

Specification

|

Working flow: 3-8 kg/min

|

Working pressure: 7~16Mpa

|

|

Power consumption: 8 KW

|

Raw material ratio: 1:1

|

|

Power supply:160V-360V

|

Equipment input air pressure: 0.75~1.5 Mpa

|

|

Total air consumption of the equipment: 0.5cubic meters/min

|

Gun cleaning method: mechanical cleaning

|

1.foaming machine polyurethane2.spray foam machine insulation polyurethane

3.polyurethane foam injection machine4.polyurea spray coating machine

5.polyurea spray

Equipment use

Insulation spraying:

insulation spraying for exterior walls, interior walls, roofs, cold storage, cabins, compartments,refrigerated trucks, tanks, etc.

Injection: solar water heaters, thermal insulation water tanks, cabins, thermal insulation panels, security doors, refrigerators,pipelines, road construction, production packaging, mold filling, wall sound insulation, etc.

Injection: solar water heaters, thermal insulation water tanks, cabins, thermal insulation panels, security doors, refrigerators,pipelines, road construction, production packaging, mold filling, wall sound insulation, etc.

some spare parts for sale

Precautions

1. This machine is a high-voltage equipment and must work in accordance with the operating procedures. During work, the injection port must not be aimed at any part of the human body to avoid accidents.

2. The polyurea raw material is a high molecular compound, which is prone to static electricity when rubbed. Therefore,

flammable and explosive items should be kept away from the work site.

3. The ground wire of the equipment must be connected properly. (PE line)

4. Before using the equipment, the operator should carefully read the equipment instruction manual.

5. Do not put any part of the body in the spray range, do not point the muzzle at people with game actions, and absolutely do not look into the small hole in the mixing chamber of the gun. Due to the use of harmful substances in the raw materials, it is recommended that the operator wear a mask, gloves and goggles when using!

2. The polyurea raw material is a high molecular compound, which is prone to static electricity when rubbed. Therefore,

flammable and explosive items should be kept away from the work site.

3. The ground wire of the equipment must be connected properly. (PE line)

4. Before using the equipment, the operator should carefully read the equipment instruction manual.

5. Do not put any part of the body in the spray range, do not point the muzzle at people with game actions, and absolutely do not look into the small hole in the mixing chamber of the gun. Due to the use of harmful substances in the raw materials, it is recommended that the operator wear a mask, gloves and goggles when using!

Hot Searches