Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

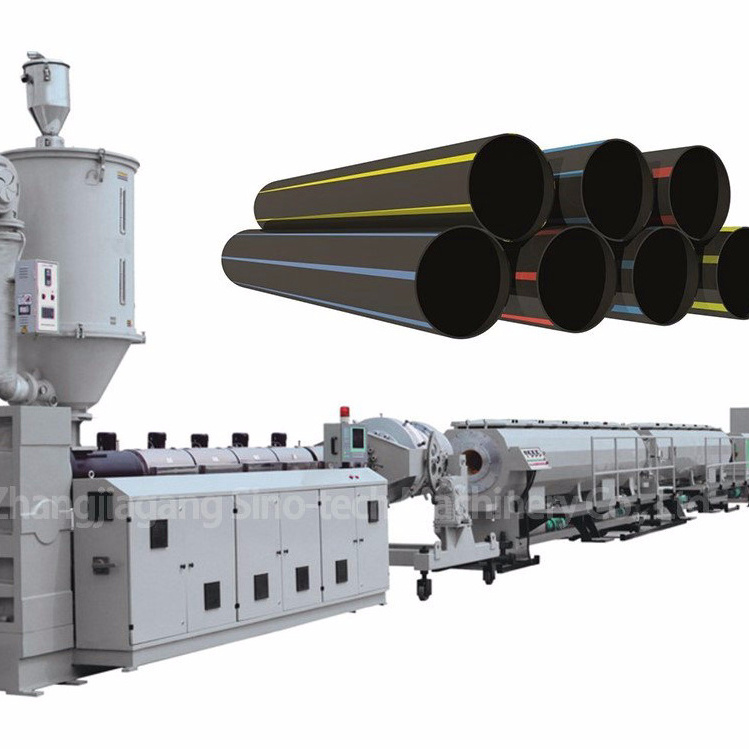

Sino-Tech

-

Voltage:

-

380V 3phase 50Hz (Customized)

-

Weight:

-

35000 KG

-

Name:

-

HDPE Pipe Production Making Machine

-

Motor:

-

Siemens

-

Inverter:

-

ABB

-

Pipe Diameter:

-

75-250mm

-

Color:

-

Customized

-

Type:

-

Production Line

-

Extrusion Capacity:

-

350kg/h

-

Cutting Type:

-

Planetary Cutter

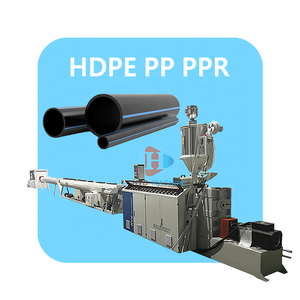

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

70 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sino-Tech

-

Voltage:

-

380V 3phase 50Hz (Customized)

-

Weight:

-

35000 KG

-

Name:

-

HDPE Pipe Production Making Machine

-

Motor:

-

Siemens

-

Inverter:

-

ABB

-

Pipe Diameter:

-

75-250mm

-

Color:

-

Customized

-

Type:

-

Production Line

-

Extrusion Capacity:

-

350kg/h

-

Cutting Type:

-

Planetary Cutter

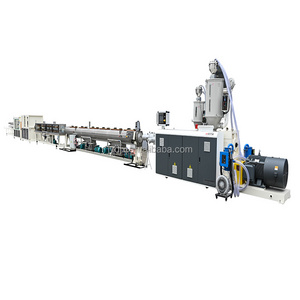

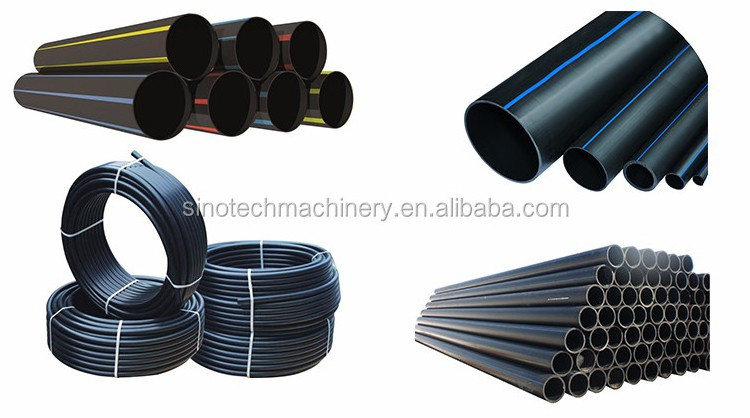

Plastic HDPE Agricultural Irrigation Pipe Gas Tube Production Line Extruder Machine

HDPE Pipe Application:

Agricultural Irrigation water supply&Sweage drainage pipe&Discharge system&Gas supplly system&Architectural water supply.

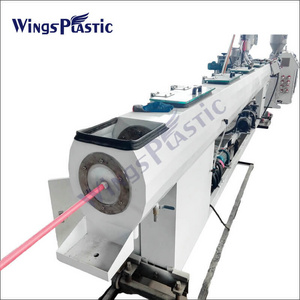

Production Flow of Pipe Production Line:

Material →Color Mixer →Automatic Feeder→Hopper Dryer →Single Screw Extruder →Extrusion Mould & Calibrator → Vacuum Calibration Cooling Tank → Spray Cooling Tank →Printer → Haul-off Unit →Cutter →Stacker or Coiler

Features of Pipe Machiner:

1- 30m/min of maximum lineal extrusion speed, big capacity and low power consumption, and achieved multi- layers co extrusion with 1-5 layers.

2- The copper bush is more wear-resisting and prevent material leakage which can guarantee a stable running of extruder.

3- Material feed via spiral groove, efficient transmission and can effectively reduce back-pressure on extruder.

4- Unique design (barrier, shearing and mixing zone) guarantees a uniformed plasticizing effect, and can reduce the pressure on the screw which guarantees a high speed and stable output capacity.

5- High torque gear box has a smart figuration, compact construction, low noise, high carrying capacity, high transmission efficiency can assure long-time trouble-free operation;

6- PCA(pipe air cooling system) of die head largely increase the extrusion speed and decrease the cooling length of extrusion line, and improve quality of inner pipe surface;

7- Intelligent PLC controlling system with human-friendly interface make the operation easily and conveniently;

8- Chip-free cutter ensuing flat and smooth cutting surface of pipe.

Main Technical Parameter:

|

Machine

|

Pipe diameter |

Vacuum Calibration Tank |

Spray Cooling Tank |

Haul-off unit |

Cutter |

||||

|

Vacuum pump |

Water

|

Length(mm) |

Water

|

Length(mm) |

caterpillar Quantity |

Motor |

Cutting type |

||

|

HDPE63 |

φ16mm-φ63mm |

3kw*2 |

3kw*2 |

6000mm |

3kw*1 |

6000mm |

2 |

1.5kw*2 |

No dust cutter |

|

HDPE-110C |

Φ40mm-φ110mm |

4kw*2 |

3kw*2 |

6000mm |

3kw*1 |

6000mm |

2 |

3kw |

No dust cutter |

|

HDPE-160 |

Φ50mm-φ110mm |

4kw*2 |

4kw*2 |

6000mm |

4kw*1 |

6000mm |

3 |

1.1*3 |

Planetary cutter |

|

HDPE-250 |

Φ75mm-φ250mm |

5.5kw*2 |

5.5kw*2 |

6000mm |

4kw*1 |

6000mm |

3 |

1.1kw*3 |

Planetary cutter |

|

HDPE-315 |

Φ110mm-φ315mm |

5.5kw*2 |

5.5kw*2 |

6000mm |

5.5kw*1 |

6000mm |

4 |

1.1kw*4 |

Planetary cutter |

|

HDPE-630 |

Φ315mm-φ630mm |

7.5kw*2 |

7.5kw*2 |

6000mm |

7.5kw*1 |

6000mm |

6 |

1.1kw*6 |

Planetary cutter |

|

HDPE-800 |

Φ400mm-φ800mm |

5.5kw*2(2m) |

5.5kw*2(2m) |

6000mm |

5.5kw*2 |

6000mm |

8 |

1.1kw*8 |

Planetary cutter |

|

7.5kw*2(10m) |

7.5kw*2(10m) |

||||||||

|

HDPE-1200 |

Φ630mm-φ1200mm |

5.5kw*2 |

7.5kw*2 |

6000mm |

7.5kw*2 |

6000mm |

10 |

1.1kw*10 |

Planetary cutter |

If you have any questions, please contact us:

Mob/Whatsapp/Wechat:+86 13915728281