- Product Details

- {{item.text}}

Quick Details

-

Power:

-

15000

-

Dimension(L*W*H):

-

9200x1600x1750mm

-

Weight:

-

5000 kg

-

Name:

-

hand paper bag machine

-

Application:

-

used paper bag production machine

-

Paper Roll Width:

-

245-580mm

-

Bag Width:

-

80-190mm

-

Bag Length:

-

190-371mm

-

Bottom Width:

-

45-100mm

-

Paper Thickness:

-

65-120g/m²

-

Max. Paper Roll Diameter:

-

1500mm (59'')

-

Material Core Diameter:

-

76mm(2.99'')

-

Keyword:

-

manual paper bag making machine

Quick Details

-

Production Capacity:

-

200 pcs/min

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V50HZ

-

Power:

-

15000

-

Dimension(L*W*H):

-

9200x1600x1750mm

-

Weight:

-

5000 kg

-

Name:

-

hand paper bag machine

-

Application:

-

used paper bag production machine

-

Paper Roll Width:

-

245-580mm

-

Bag Width:

-

80-190mm

-

Bag Length:

-

190-371mm

-

Bottom Width:

-

45-100mm

-

Paper Thickness:

-

65-120g/m²

-

Max. Paper Roll Diameter:

-

1500mm (59'')

-

Material Core Diameter:

-

76mm(2.99'')

-

Keyword:

-

manual paper bag making machine

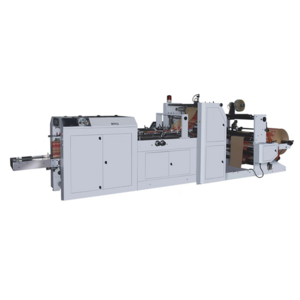

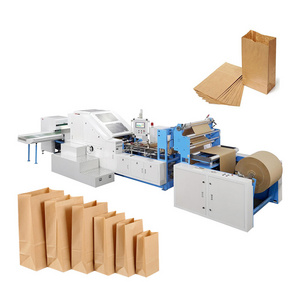

CY-180 Low Cost Zipper Pouch Paper Bag Making Machine/Paper Tissue Bag Making Machine/Bread Paper Bag Machine

Brief introduction of paper bag machine :

This Full automatic square bottom paper bag making machine is designed to manufacture square bottom paper bags from paper roll in blank or printed.It can finishes all procession all in a time consisting: perforating, middle gluing,printed pattern calibration, tube forming, calibration snapping, bottom folding, bottom forming, and collect final product quantitatively. Suitable for varied primary and printed rolling paper, such as Kraft paper,slick paper,coated paper,medico paper and so on.It is ideal equipment for making paper bag for foodstuff bag, shopping bag and so on. Controlled by PLC system, equipped with in-touch screen and servo motor for bag length control, this machine can produce different size paper bag.

Characteristics:

1. Accurate photocell system for printed mark tracking, Color mark error stopping system . Tracking the printed material accurately, minimize the adjustment and preset time, increase the production efficiency

2.PLC and In-touch screen human-machine interface centralized control system, with reliable performance, easy for operation and maintenance. English/Chinese language can be changed easily.

3 .Paper impress, bottom folding, gluing and bag formation can be completed automatically

4.Automatic fault detector and self diagnosis system reduce the chance to damage machine.

| Technical Parameters of Paper Bag Machine | |||

| Model | CY-180 | CY-290 | CY-460 |

|

Paper Roll Width |

245-580mm |

320-900mm |

600-1300mm |

|

Bag Width |

80-190mm |

80-290mm |

220-460mm |

|

Bag Length |

190-371mm |

260-533mm |

155-505mm |

|

Bottom Width |

45-100mm |

60-160mm |

60-180mm |

|

Paper Thickness |

65-120g/m² |

65-150g/m² |

65-180g/m² |

|

Max. Paper Roll Diameter |

1500mm (59’’) |

1500mm (59’’) |

1500mm (59’’) |

|

Material Core Diameter |

76mm(2.99’’) |

76mm(2.99’’) |

76mm(2.99’’) |

|

Max. Production Speed |

200pcs/min |

200pcs/min |

180pcs/min |

|

Total Power |

15kw |

15kw |

15kw |

|

Machine Weight |

5000kg |

8500kg | 10000kg |

|

Machine Size |

9200*1600*1750mm | 8600*2500*1800mm |

8600*3000 *1800mm |

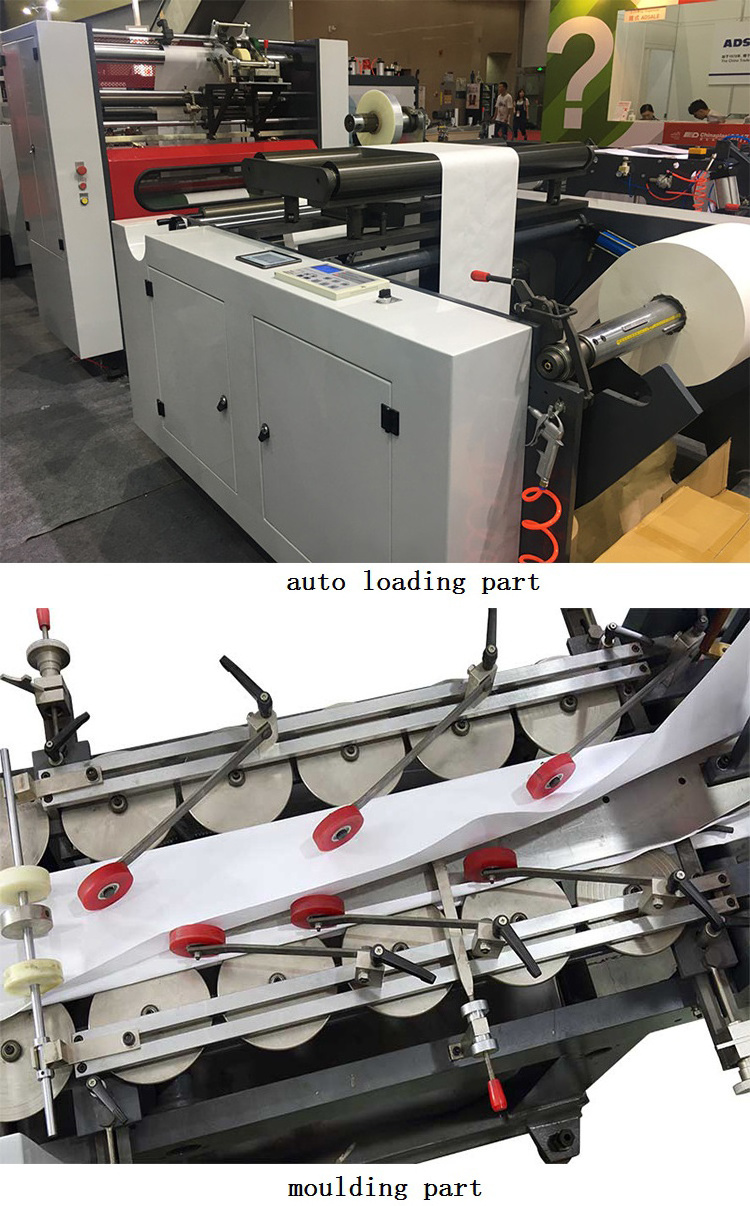

Product Details:

Different parts show:

Product Details:

Different parts show:

WHY DO YOU CHOOSE US?

BECAUSE

1.Better Material:

We choose better materials in the market to produce, improve the quality from the source, for your escort along the way.

2.Fine Workmanship:

We have standardized production process, strict supervision mechanism and constantly updated product technology.

3.Quality Guarantee:

Before leaving the factory, our products are strictly tested and the quality of each product is guaranteed.

4.Rest Assured After-sales:

We are a large manufacturer, there are specialized after sales and maintenance personnel, can reduce the customer's concern, welcome the customer to visit the factory to discuss.

![[JT-HY270]CE Paper Bag Making Min Machine German Paper Bag Making Machine Manual Paper Bag Making Machine Price](https://cdn.bestsuppliers.com/seo_products_img/jeta/17c1ba615af43136bdaced2ec254d76c.jpg!/rotate/180/sq/300)