- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Tint Glass

-

Thickness:

-

6mm 8mm 10mm 12mm

-

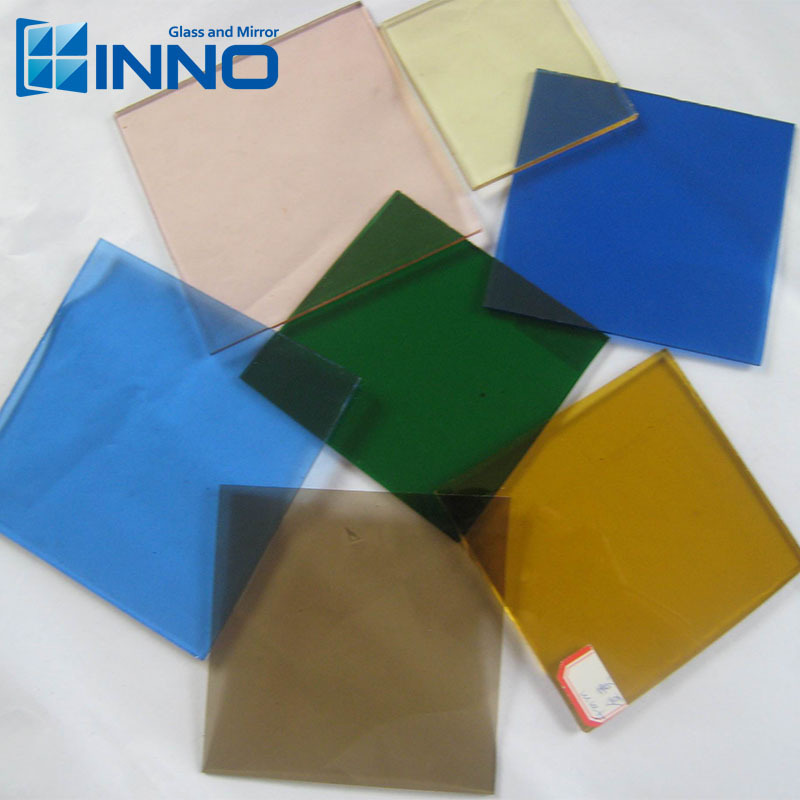

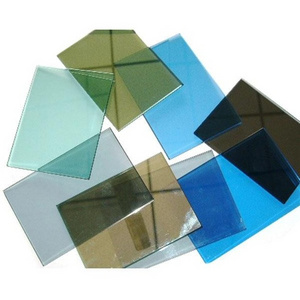

Color:

-

Blue,green,bronze,pink,black

-

Material Type:

-

clear float glass,patterned glass,low iron glass

-

Size:

-

Custom design

-

Tolerance:

-

+/- 0.2mm

-

Edge:

-

rough,polished,flat,round,pencil,beveled

-

Certificate:

-

AS/NZS2208,CCC,CE,ISO

-

Surface Treatment of Tempered Glass:

-

clear and colored logo,silkscreen printing,frosted

-

Delivery of Tempered Glass:

-

within 7-10 days after deposited

-

Available Process of Tempered Glass:

-

cut,grind,drill,silkscreen printing,frosted,acid etched

Quick Details

-

Application:

-

Hotel

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

tempered glass

-

Model Number:

-

Tint Glass

-

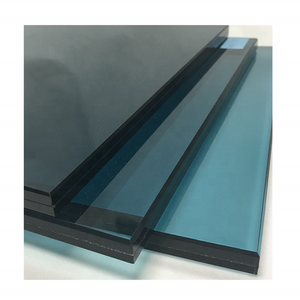

Thickness:

-

6mm 8mm 10mm 12mm

-

Color:

-

Blue,green,bronze,pink,black

-

Material Type:

-

clear float glass,patterned glass,low iron glass

-

Size:

-

Custom design

-

Tolerance:

-

+/- 0.2mm

-

Edge:

-

rough,polished,flat,round,pencil,beveled

-

Certificate:

-

AS/NZS2208,CCC,CE,ISO

-

Surface Treatment of Tempered Glass:

-

clear and colored logo,silkscreen printing,frosted

-

Delivery of Tempered Glass:

-

within 7-10 days after deposited

-

Available Process of Tempered Glass:

-

cut,grind,drill,silkscreen printing,frosted,acid etched

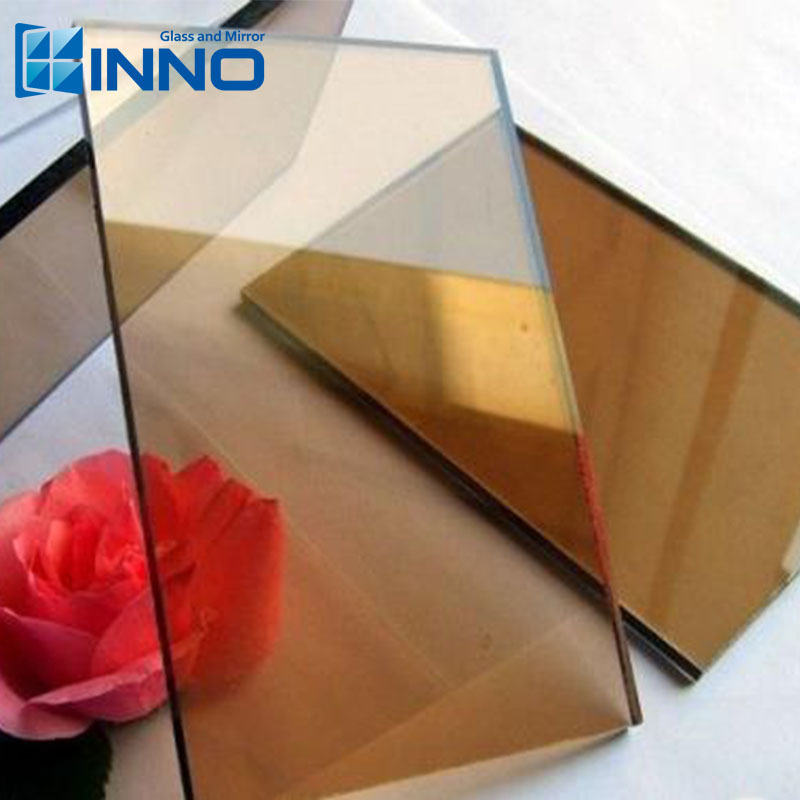

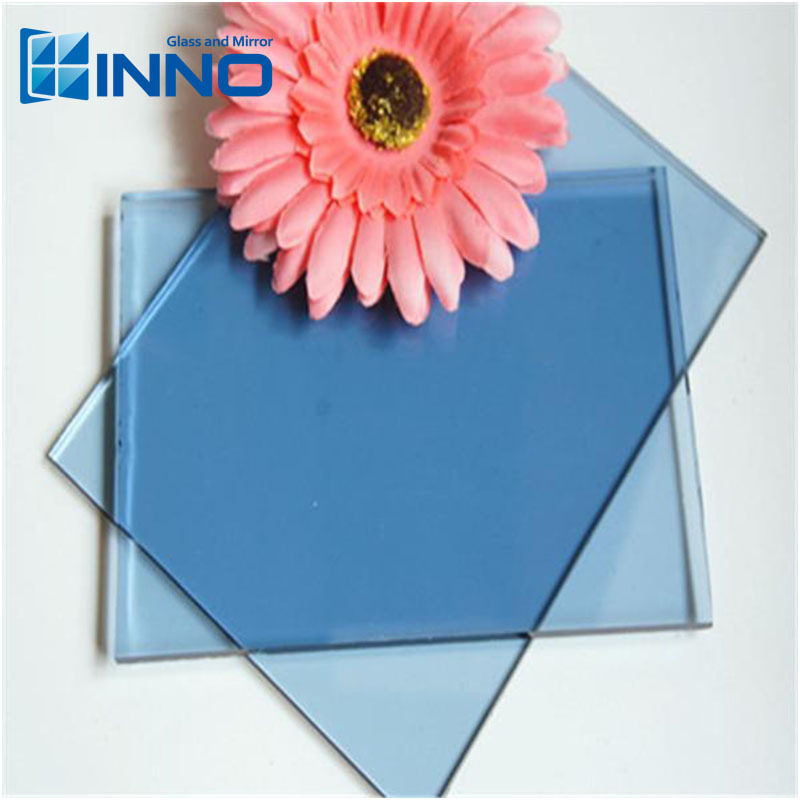

Features of Tinted Float Glass :

tinted tempered glass is produced by the float process with the addition of small quantities of metal oxides to color the normal clear glass mix. This coloration is achieved through adding metal oxides at the smelting stage. Addition of color does not affect the basic properties of the glass, even though visible light reflectance will be slightly higher than clear glass.

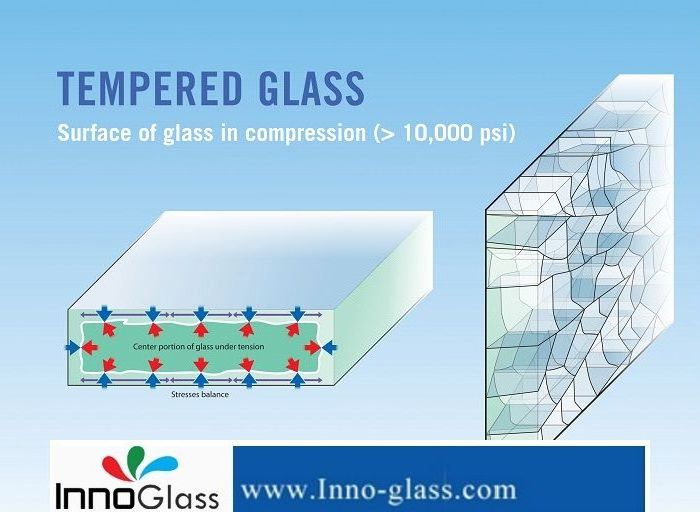

Advantage of Tempered Glass :

Safety

- Safety is the main advantage of tempered glass. Using tempered glass reduces the risk of injury caused by jagged glass shards. A glass that does not shatter into razor-sharp slivers can be used in places where breakage is inevitable.

- Tempered glass breaks into small, circular "pebbles" because of the way the molecules bond. It will also shatter evenly and crumble into small pieces even if force is applied at one end. That means larger shards of broken glass will not crack off and fly through the air when the glass is broken. This makes it much more desirable for use in cars and trucks.

Clean-up

- Tempered glass is easier to clean up. Since it crumbles into small pieces, there are fewer sharp shards and splinters that are difficult to pick up with a broom. Tempered glass can be swept up much like small rocks with a push broom, and thrown away in a dumpster without fear of the glass slitting open the trash bags or injuring a waste management worker. In addition, if any glass is left behind, there is less of a chance that it will injure someone. The glass "pebbles" can also be vacuumed.

Strength

- Tempered glass is much stronger than regular glass. The process used to make it causes a stronger bond between the molecules in the glass. This means the glass can be used in applications that require a stronger surface that is see-through, like windshields in cars and trains, windows in laboratories and glass walkways.

Heat Resistance

- Tempered glass is also more heat resistant than normal glass. This is another effect of the process to "cure" the glass. Since heat is applied during the process, the molecules become more resistant to higher temperatures. The glass will not melt or weaken even when flame is applied directly. This makes it ideal for laboratory uses, fire engines and buildings that must be built to strict fire codes.

Other Considerations

- Tempered glass also has many intangible advantages. Since it reduces the risk of injury, it also reduces the risk of lawsuits. It is ideal for public buildings and private companies that have lots of visitors and could be held liable for damages if a glass pane breaks in their building and someone is injured. That is also true for industrial companies where workers depend on safety glass to protect them from heat and flying objects on the job. It is used in hockey rinks to protect fans from flying pucks, and it can withstand a direct hit from a 100mph slap shot. It won't crack and injure fans or players that are checked into the boards, even when it breaks.

Follow us to see how we tempered the glass to customer design:

1.Cut the glass into the desired shape first.

This has to be done before the glass is tempered, as the tempering process will weaken the glass if it is cut or etched afterward and may increase the likelihood of breakage.

2.Inspect the glass for imperfections. Cracks or bubbles may cause the glass to break during tempering; if any are found, the glass cannot be tempered.

3.Grind the cut edges smooth. This removes any burrs created during cutting or etching.

4.Wash the glass. This removes any tiny grains of glass deposited during sanding, as well as any dirt that may interfere with the tempering process.

5.Heat the glass in a tempering oven. Glass may be fed in batches or continuously. The oven reaches temperatures of over 600 degrees Celsius (1,112 degrees Fahrenheit), with the industry standard being 620 degrees Celsius (1,148 degrees Fahrenheit).

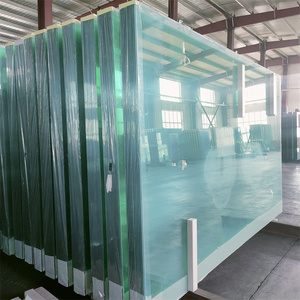

Usual Settings of Tempered Glass

|

Products |

Tinted Float Glass | ||||||||

| Thickness | 3mm,4mm,5mm,6mm,8mm,10mm,12mm,15mm,19mm | ||||||||

| Sizes | MIN:20MM*20MM MAX :3600*12000MM | ||||||||

| Tolerance:+/-0.2mm | |||||||||

| Specification | a) Surface treatment: acid etched,frosted,silkscreen printing | ||||||||

| b) Thickness 3mm, 4mm,5mm,6mm,8mm,10mm | |||||||||

| c) Color : Bronze,Grey, Green, Blue,Pink,Black, Yellow etc | |||||||||

| d) Edge :Flat edge,grind edge,High polished edge,bevelled edge and others | |||||||||

| e) Corne r:natural corner,grind corner,round corner with fine polished | |||||||||

| f) Holes :Drill work available at customer's option | |||||||||

| Feature | 1.Perfect color series and color consistency | ||||||||

| 2.High Light Transmittance | |||||||||

| 3.Offer heat insulation and energy savings | |||||||||

| 4.Enhances architectural apparence | |||||||||

| Delivery details | Within 10-15 days after receiving your deposit | ||||||||

| Packing details | 1.interlay paper or plastic between two sheets | ||||||||

| 2 .seaworthy wooden crates | |||||||||

| 3 .iron belt for consolidation | |||||||||

| Quality standard | CE certificate,AS/NZS certificate,3Ccertificate and Fire-proof | ||||||||

| Payment terms | 30%T/T in advance,balance before the shipment or by L/C. | ||||||||

Available Surface Treatment of Tinted Float Tempered Glass

Application of Tinted Float Glass

Suitable where safety glazi ng is required by building codes or design specifications

Commerical and civil building

Interior Decoration

Show window

InnoGlass Technology (Qingdao) Co.,Ltd is a professional glass manufacture with strong technology research and development ability ,

Our main products including wide ranges:

The smart switchable PDLC glass and film, transparent LCD display ,

Silkscreen printing glass,home appliance glass,furniture glass,

Tempered glass,mirror,solar glass,low-e glass etc.

For the silkscreen printing glass, we achieve colorful, super adhesion combined specializing in high demand products,for example home appliances panels, decorative glass , furniture glass and so on !

On the switchable smart PDLC glass film, Inno-glass cooperate with Korea factory based on our own research and development to achieve ultra- thin , UV resistant, high transmittance, oversized products by hardening , coating , laminating , plastic folders and other production processes

For the Transparent LCD display,totally innovative products, they can be used for Showcase,

advertising,building,fridge door and so on;

Our advantages:

1. Strong technology research team;

2. Advanced equipment guarantee the quality of products;

3. Perfect quality products meet ISO9000,3C,CE,etc;

4. Professional management team, based on customers need, design and manufacture products, creating value for customers ;

5. Customer first has always been our service concept;

1.What is the MOQ?

The MOQ is 2-10 Pieces

2.Can we design the size,logo and edge?

Of course you can,actually,it's the most important,YOUR IDEA !

3.How long can I get the sample if need?

Within 3-7 days depends on the process way

4.How can we contact with you?