- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Gondor

-

Voltage:

-

220V 380V

-

Power:

-

4.5kw 6kw 12kw 15kw

-

Dimension(L*W*H):

-

2350*1320*1900mm

-

Weight:

-

3000 kg

-

Paper bowl Size:

-

1400-1500ml

-

Paper cup Size:

-

1.5-16oz

-

Paper Material Requirements:

-

Single and double laminated paper

-

Application:

-

Coffee paper cups, paper bowls, breakfast bowls, instant noodle bowls

-

Cup Side Sealing:

-

Ultrasonic

-

Bottom Knurling:

-

Hot air syetem

-

Certificate:

-

ISO 9001, ISO 14001, ISO 45001, CE, BSCI, ETL

-

Advantage:

-

Automation and intelligence

-

Paper weight:

-

160-340g/㎡;±20g/㎡

-

Working Air Source:

-

0.4-0.6Mpa; 0.4m³/min

Quick Details

-

Production Capacity:

-

40-110pcs per min

-

Product Type:

-

Paper cup and Bowl Machine

-

Place of Origin:

-

Made in China

-

Brand Name:

-

Gondor

-

Voltage:

-

220V 380V

-

Power:

-

4.5kw 6kw 12kw 15kw

-

Dimension(L*W*H):

-

2350*1320*1900mm

-

Weight:

-

3000 kg

-

Paper bowl Size:

-

1400-1500ml

-

Paper cup Size:

-

1.5-16oz

-

Paper Material Requirements:

-

Single and double laminated paper

-

Application:

-

Coffee paper cups, paper bowls, breakfast bowls, instant noodle bowls

-

Cup Side Sealing:

-

Ultrasonic

-

Bottom Knurling:

-

Hot air syetem

-

Certificate:

-

ISO 9001, ISO 14001, ISO 45001, CE, BSCI, ETL

-

Advantage:

-

Automation and intelligence

-

Paper weight:

-

160-340g/㎡;±20g/㎡

-

Working Air Source:

-

0.4-0.6Mpa; 0.4m³/min

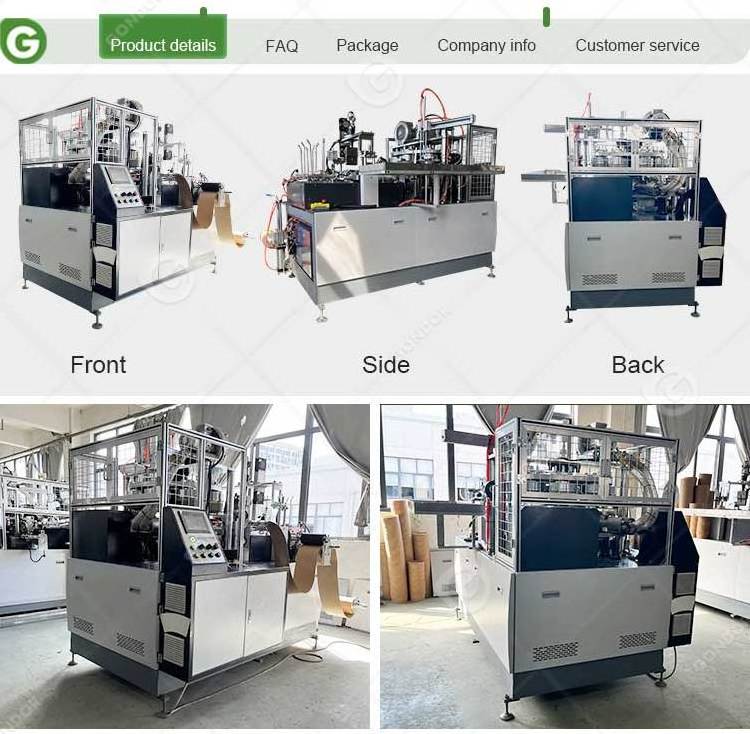

Introduction

The paper bowl machine is an industrial equipment specially used to manufacture paper bowls. It uses an automated process to make paper bowls from specific paper materials. Paper bowl machines offer different customization options, including machine size, degree of automation, production speed, etc., to meet different scale production needs.

Application

1. Can be used to produce paper cups, advertising paper cups, ice cream cups, coffee cups, paper bowls, breakfast bowls, instant noodle bowls, soup bowls and cold drink paper bowls, etc.

2 . Suitable for catering industry, hotel industry, tourism industry, etc.

Features

1. The touch screen interacts with the PLC, and parameters can be set and adjusted on the control panel.

2 . The bottom paper feeding is controlled by servo motor, with few failures.

3 . The inside of the machine is connected by groove wheels, and all parts are tightly connected.

4 . Adopt direct bottom punching and bottom feeding method to avoid bottom flipping.

Paramater

| Model | GD-D800 | GD-T185 |

| Power | 12kw | 15kw |

| Max paper bowl size | 1400ml | 1500ml |

| Working Air Source | 0.6-0.8Mpa; 0.4m³/min | 0.5-0.8Mpa; 0.6m³/min |

| Paper Material Requirements | Single and double laminated paper | |

| Output | 60-70 pcs/min | 40-60pcs/min |

| Paper weight | 200-330g/ m ² ;±20g/ m ² | 240-340g/ m ² ;±20g/ m ² |

| Bowl size |

Bottom:80-125mm,Top:100-148mm;

Height: 125mm. |

Bottom:125-165mm,Top:150-185mm;

|

| Size | 2350*1320*1900mm | 2150*1320*1900mm |

| Weight | 3000kg | 2800kg |

| Cup Side Sealing | Ultrasonic | |

| Bottom Knurling | HOT AIR SYETEM | |

Q1. What is the main use of paper bowl machine?

Paper bowl machines are used to produce paper bowls, which are usually used for packaging of fast food, ice cream, soup and other foods.

Q2. What is the production capacity of the paper bowl machine?

Depending on the machine model, it can produce dozens to hundreds of paper bowls per minute.

Q3. How difficult is it to operate a paper bowl machine?

Modern paper bowl machines are generally designed to be easy to operate, with many models featuring a high degree of automation, making operation less difficult.

Q4. What sizes of paper bowls can the paper bowl machine produce?

Paper bowls of different sizes can be produced, depending on the mold and machine configuration.

Q5. What are the maintenance requirements for paper bowl machines?

Clean, lubricate and inspect worn parts regularly to ensure continued stable operation.

Installing waterproof membrane to reduce dust and water pollution

Standard wooden boxes are used as outer packaging to reduce bumps in international transportation

Delivery Time

For stock type, we can send within 48hrs after confirming order.

For customized type , delivery date need to be negotiated before taking order.