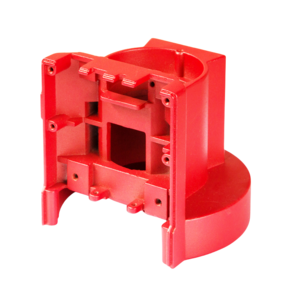

Custom Sand Castings

From simple to complex metal parts, sand casting is a versatile casting process. Due to this versatility, custom sand cast parts

can be manufactured in a wide variety of shapes and sizes, most metal alloys and small to large quantities. As a custom

sand-casting supplier, XHX Precision Industry provides high-quality machined castings. Our state-of-the-art foundry, machining and

surface finishing equipment ensures the best quality parts. We are very reliable and offer stocking programs in our warehouse.

Make XHX Precision Industry your best choice for custom sand cast parts for all commercial industries as well as all architectural

applications.

We use the sand casting process to produce a wide range of parts in many different metals. We supply as-cast parts but prefer to

supply machined castings, as this helps us find defects during the machining process, before shipping to you.

- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Aluminum/Stainless steel/iron

-

Surface treatment:

-

Powder Coating

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Certification:

-

ISO9001/IATF16949

-

Dimensions:

-

20~3000mm

-

Quality Control:

-

100% Inspected /ISO9001 System

-

Tolerance:

-

CT6-CT7

-

Drawing format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

MOQ:

-

1 Piece

-

Machining Process:

-

Die Casting-CNC Finishing Process

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

XHX

-

Model Number:

-

XHX-002

-

Material:

-

Aluminum/Stainless steel/iron

-

Surface treatment:

-

Powder Coating

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Certification:

-

ISO9001/IATF16949

-

Dimensions:

-

20~3000mm

-

Quality Control:

-

100% Inspected /ISO9001 System

-

Tolerance:

-

CT6-CT7

-

Drawing format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

MOQ:

-

1 Piece

-

Machining Process:

-

Die Casting-CNC Finishing Process

|

Application

|

Heavy truck parts/ Light Truck parts/ Valve / Pump / Agriculture Machinery / Elevator Part / Construction Tools / Printing Press

Equipment / Auto Parts / Fireflghting Equipment /etc |

|

Process

|

Mold Macking, Casting, Machining, Surface treatment, Inspection, Packing, Loading

|

|

Materials

|

Aluminium, Grey cast iron, Ductile cast iron, Carbon steel, Stainless steel, etc

|

|

Casting technical

|

Clay dry sand casting / resin sand casting / precision casting / investment casting / lost wax casting / shell-mould / silica sol casting / water glass casting

|

|

Casting blank size

|

2mm-1500mm / according to customer's requirement

|

|

Casting blank weight

|

0.01kg-2000kg

|

|

Casting tolerance

|

CT5-CT8

|

|

Machining tolerance

|

0.01mm

|

|

Machining

|

Lathing / Milling / Turning / Boring / Drillig / Tapping / Grinding / etc

|

|

Surface quality

|

Ra0.8-Ra3.2 / according to customer requirement

|

|

Surface treatment

|

Shot blasting / Polishing / Painting / Powder coating / Anodizing / Zinc plating / Nickel plating / blacking / etc

|

|

Quality control

|

100% inspection berore shipment

|

|

Design / File / formats

|

3D, Auto CAD (IGS,DXF,DXF,DWG,STP, STEP,STL,X-T) / Soild Works / Unigraphics / PDF /etc

|

|

Certification

|

ISO9001:2015, IATF16949

|

|

Package

|

Bubble plastic bag / polybag / pallet / wooden case etc

|

|

Sample

|

Available

|

|

OEM service

|

Available

|

Custom Die Casting

The die casting process utilizes die molds that are injected with high-pressure liquid metal to create parts, components and

custom products. The ability to produce a large number of products at a very low cost per unit is one of the biggest draws of

custom die casting. There are also a broad range of metal alloys that can be used within the die casting process, including

aluminum, copper, magnesium, zinc and other special die casting alloys.

XHX Precision Industry provides premium quality custom die casting services for your part, component and product needs. The die

casting process also allows for the creation of parts with complex shapes and unique tolerances. Our custom die cast products can

be created with very short leads, which allows for quicker customer turnaround times. At Deeco Metals, we can create die castings

that range from a couple Grams to 100s of kgs.

The die casting process utilizes die molds that are injected with high-pressure liquid metal to create parts, components and

custom products. The ability to produce a large number of products at a very low cost per unit is one of the biggest draws of

custom die casting. There are also a broad range of metal alloys that can be used within the die casting process, including

aluminum, copper, magnesium, zinc and other special die casting alloys.

XHX Precision Industry provides premium quality custom die casting services for your part, component and product needs. The die

casting process also allows for the creation of parts with complex shapes and unique tolerances. Our custom die cast products can

be created with very short leads, which allows for quicker customer turnaround times. At Deeco Metals, we can create die castings

that range from a couple Grams to 100s of kgs.

Custom Investment Castings

Investment casting, in which molten metal is poured into an expendable ceramic mold, is one of the world's oldest manufacturingprocesses, dating back thousands of years. The mold is formed by using a wax pattern or model-a disposable piece in the shape of the desired part.

The wax model or pattern can be used by itself to cast a single piece or attached to a wax "casting tree" (or gating system), with multiple other pieces for higher volume production. The wax model or casting tree is first dipped into a ceramic slurry, then into a ceramic powder, multiple times, until a thick coa forms around the model and/or tree. The resulting ceramic mold is then cured to achieve the required hardness that finally becomes the mold for the investment casting process.

Investment casting is often referred to as "lost-wax casting" because the original wax pattern is melted out of the mold after the ceramic has cured. The base metal being used is then poured into the remaining cavity, filling the inside shape.

Investment casting, in which molten metal is poured into an expendable ceramic mold, is one of the world's oldest manufacturingprocesses, dating back thousands of years. The mold is formed by using a wax pattern or model-a disposable piece in the shape of the desired part.

The wax model or pattern can be used by itself to cast a single piece or attached to a wax "casting tree" (or gating system), with multiple other pieces for higher volume production. The wax model or casting tree is first dipped into a ceramic slurry, then into a ceramic powder, multiple times, until a thick coa forms around the model and/or tree. The resulting ceramic mold is then cured to achieve the required hardness that finally becomes the mold for the investment casting process.

Investment casting is often referred to as "lost-wax casting" because the original wax pattern is melted out of the mold after the ceramic has cured. The base metal being used is then poured into the remaining cavity, filling the inside shape.

Passivation

We offer passivation services for the removal of metal oxides; heat-treat scale, and other foreign materials from stainless steel and other metals, leaving the surface chemically clean and prepared for further processing.

Silk Screening

XHX Precision Industry offers color choices in single, dual, triple or multi-color variations and Pantene color requirements. Telecommunications and Commercial Industries use silk screening on boxes, panels and various other parts and products.

Gold Plating

Gold Plating is used for many different electronic and electrical purposes, where the part is designed to operate on complex, high-reliability electronic devices. The majority being applied to three specific types of components: semiconductors, printed/etched circuits, contacts/connectors and high-end decorative items. Industries also use Gold plating for decorative applications.

Silver Plating

Industrial Silver plating provides an economical coating typically used for telecommunication and electrical products. It bestows a surface that can be soldered and exhibits low electrical resistance. The tarnish resistance is equal to that of a good water dip lacquer coating.

We offer passivation services for the removal of metal oxides; heat-treat scale, and other foreign materials from stainless steel and other metals, leaving the surface chemically clean and prepared for further processing.

Silk Screening

XHX Precision Industry offers color choices in single, dual, triple or multi-color variations and Pantene color requirements. Telecommunications and Commercial Industries use silk screening on boxes, panels and various other parts and products.

Gold Plating

Gold Plating is used for many different electronic and electrical purposes, where the part is designed to operate on complex, high-reliability electronic devices. The majority being applied to three specific types of components: semiconductors, printed/etched circuits, contacts/connectors and high-end decorative items. Industries also use Gold plating for decorative applications.

Silver Plating

Industrial Silver plating provides an economical coating typically used for telecommunication and electrical products. It bestows a surface that can be soldered and exhibits low electrical resistance. The tarnish resistance is equal to that of a good water dip lacquer coating.

Electroless and Electro-Deposited Nickel Plating

These Nickel Plating processes deposit a uniform thickness of Nickel onto products by chemical reduction; this allows even the most complex shaped product to be plated with no edge build-up.

Shot Blast Finishing

We offer Shot Blasting operations for providing various surface finishes on Cast products. It can produce a cosmetically better-looking product. We offer various size shot for different surface finishes.

Tin Plating

Tin plating is extensively used in Food, Electrical, and Electronic Industries. Because it is safe and nontoxic, Tin is

universally utilized in the Food Processing Industry. Plus offers first-rate corrosion resistance and is pliable with low

porosity. Also used for Electrical and Electronic, Tin plating has the ability to protect base metals from oxidation, thereby preserving the potential for soldering.

Zinc and Zincate Plating

XHX Precision Industry offers two types of Zinc plating: Alkaline Zinc exhibits good brightness, ductility, and chromate receptivity, and has reliable and consistent coverage. Chloride Zinc deposits an outstanding brightness and plates difficult substrates such as castings.

These Nickel Plating processes deposit a uniform thickness of Nickel onto products by chemical reduction; this allows even the most complex shaped product to be plated with no edge build-up.

Shot Blast Finishing

We offer Shot Blasting operations for providing various surface finishes on Cast products. It can produce a cosmetically better-looking product. We offer various size shot for different surface finishes.

Tin Plating

Tin plating is extensively used in Food, Electrical, and Electronic Industries. Because it is safe and nontoxic, Tin is

universally utilized in the Food Processing Industry. Plus offers first-rate corrosion resistance and is pliable with low

porosity. Also used for Electrical and Electronic, Tin plating has the ability to protect base metals from oxidation, thereby preserving the potential for soldering.

Zinc and Zincate Plating

XHX Precision Industry offers two types of Zinc plating: Alkaline Zinc exhibits good brightness, ductility, and chromate receptivity, and has reliable and consistent coverage. Chloride Zinc deposits an outstanding brightness and plates difficult substrates such as castings.

Metal Sourcing Quality Control & Reliability

1) ISO 9001:2015

2) Raw Material Inspection

3) Computer Simulation

4) Chemical Composition Testing

5) Non Destructive Testing

6)Mechanical Properties Testing

7) Dimensional Inspection

Hot Searches