Zhejiang Ounuo Machinery Co., Ltd.

is located in Pingyang County Wenzhou City, Zhejiang Province, covering an area of 130000 square metres, 15 years deep ploughing in packaging equipment industry. Invest 200 million imported of Japan stability of the whole machine. MAZAK, OKUMA, Taiwan WELLE etc, the high-precision CNC Machine, to ensure the precision of the components and the Main products 1, series of nonwoven products, including nonwoven bag machine, nonwoven production line, nonwoven Main products 2, series of paper products, automatic paper bag machine, semi-automatic paper bag machine, roll feeding/sheet feeding etc paper packaging equipment. printing machine, nonwoven cross-cutting machine and other nonwoven matching equipment for the project.

Ounuo's Misson:

Industry Change Because of Us

Ounuo's Vision (10-15 Years):

Responsibility to Promotion Solution of Top Quality and Intelligent Bag Making Industry. Keep in mind the mission and vision and strive to provide world-class quality products and services to customers. Oyang brand is deeply loved by the global market,products in Mexico, Argentina, the United States, Romania, Poland, Vietnam, Brazil,the United Arab Emirates,India, Turkey, Egypt, Algeria, Kenya, South Africa etc and more than 120 countries and regions, The

market shares for 85%+.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ALLWELL

-

Model Number:

-

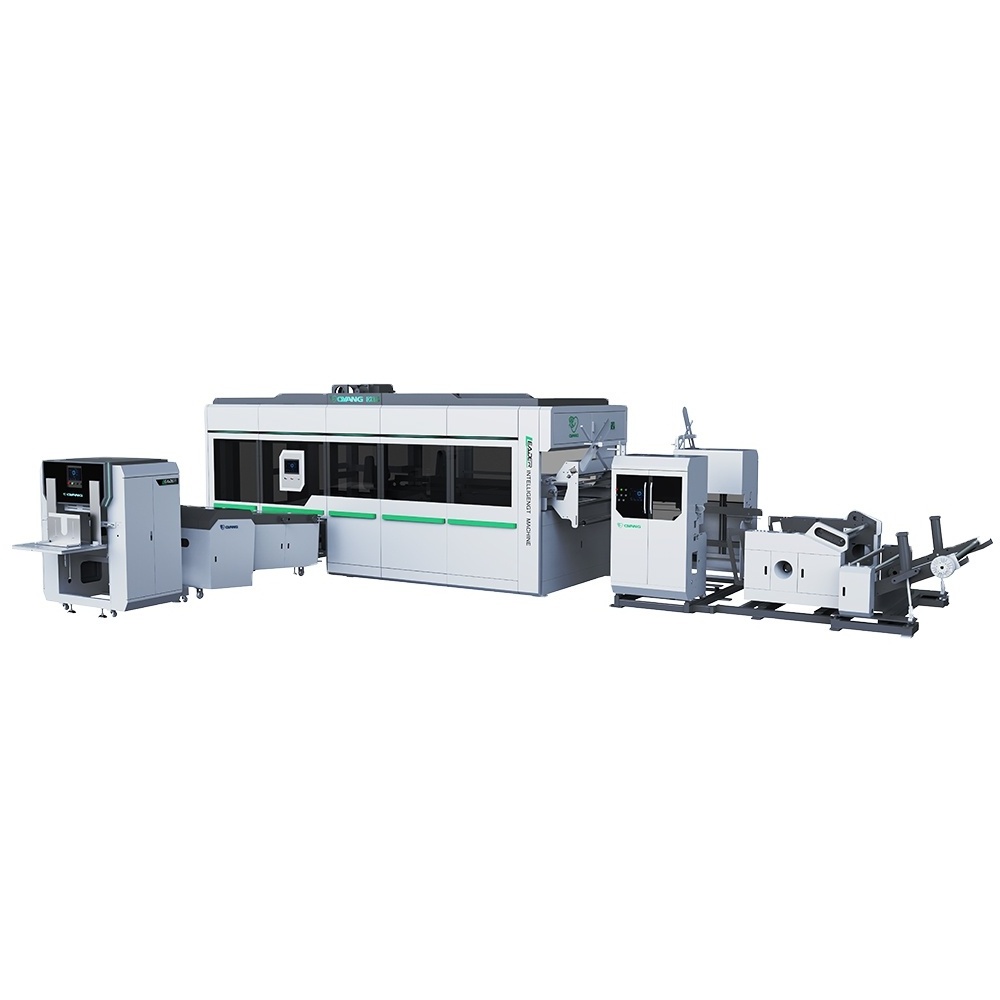

Oyang 15-Leader

-

Voltage:

-

380V 50Hz

-

Dimension(L*W*H):

-

7500x5200x2800mm

-

Weight:

-

12000 KG

-

Marketing Type:

-

New Product 2022

-

After-sales Service Provided:

-

Overseas service center available

-

Speed:

-

60-110pcs/min

-

Automatic Packing:

-

Can optional

-

Bag process:

-

One Time Forming Ultrasonic Sealing

-

Machine Host Frame:

-

The Whole Castings

-

Automatic:

-

Full-automatic

-

Suitable material:

-

Non Woven Fabric

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Shopping Bag

-

Material:

-

Non Woven Bag

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ALLWELL

-

Model Number:

-

Oyang 15-Leader

-

Voltage:

-

380V 50Hz

-

Dimension(L*W*H):

-

7500x5200x2800mm

-

Weight:

-

12000 KG

-

Marketing Type:

-

New Product 2022

-

After-sales Service Provided:

-

Overseas service center available

-

Speed:

-

60-110pcs/min

-

Automatic Packing:

-

Can optional

-

Bag process:

-

One Time Forming Ultrasonic Sealing

-

Machine Host Frame:

-

The Whole Castings

-

Automatic:

-

Full-automatic

-

Suitable material:

-

Non Woven Fabric

Oyang 15 - Leader Automatic Non-Woven Box Bag Making Machine With Handle

|

Item

|

Specification

|

|

Roller width

|

50-1100mm

|

|

Bag making speed

|

60-80pcs/min (50pcs/min using M type bottom)

|

|

Bag Width

|

100-500mm

|

|

Bag Height

|

180-450mm

|

|

Gusset

|

80-220mm

|

|

Power supply

|

380V

|

|

Total power

|

38KW

|

|

Rated power

|

29KW

|

|

Overall size

|

L 11000* W 6500* H 2600mm

|

|

Weight of Machine

|

10000KGS (40HQ*1)

|

|

Handle Length

|

370-600mm

|

|

Handle Width

|

25mm

|

FAQ

Q1.

How long will your engineer reach our factory?

Our After-sales Specialist would contact with you, confirm the final scheduling according to your reasonable request.

Q2. How many days will you finish installing?

We will finish installation and training within 7-10 days.

Q3. What should we charge for your engineer?

You should charge for the cost of our engineer's visa, air tickets,SIM card, hotel, food, and also their salary 150 USD one day per person.

Q4. How long is your machine's warranty period?

All our machine have one year guarantee, starting from finished installation.

Q5. How could we do after one year warranty period?

We also can do service for you, but you need pay salary for my technician 80USD/day.

Q6. How could we do if the parts broken within warranty?

We would express the free replacement parts during the warranty date.

Q7. Does your engineer understand English?

Our engineers understand a little English. All of our engineer have more than five years machine installation experience. In addition, they can use body language to communicate with customer.

Q8. How do we solve the machine problem after your engineer leaving?

Generally speaking, there will be no problem after finish installing. In case you have any problem. You can contact our after sales specialist at any time.Our after-sales department with 30 engineers.Our engineers will take a solution video according your description.

Q9. How many workers do we need running those machines?

Except two for bag making machine, flexo printing machine, slitting machine, ultrasonic sewing machine, hydraulic punching machine only need one person for each.

Our After-sales Specialist would contact with you, confirm the final scheduling according to your reasonable request.

Q2. How many days will you finish installing?

We will finish installation and training within 7-10 days.

Q3. What should we charge for your engineer?

You should charge for the cost of our engineer's visa, air tickets,SIM card, hotel, food, and also their salary 150 USD one day per person.

Q4. How long is your machine's warranty period?

All our machine have one year guarantee, starting from finished installation.

Q5. How could we do after one year warranty period?

We also can do service for you, but you need pay salary for my technician 80USD/day.

Q6. How could we do if the parts broken within warranty?

We would express the free replacement parts during the warranty date.

Q7. Does your engineer understand English?

Our engineers understand a little English. All of our engineer have more than five years machine installation experience. In addition, they can use body language to communicate with customer.

Q8. How do we solve the machine problem after your engineer leaving?

Generally speaking, there will be no problem after finish installing. In case you have any problem. You can contact our after sales specialist at any time.Our after-sales department with 30 engineers.Our engineers will take a solution video according your description.

Q9. How many workers do we need running those machines?

Except two for bag making machine, flexo printing machine, slitting machine, ultrasonic sewing machine, hydraulic punching machine only need one person for each.

Hot Searches