- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

Neworigin

-

Model Number:

-

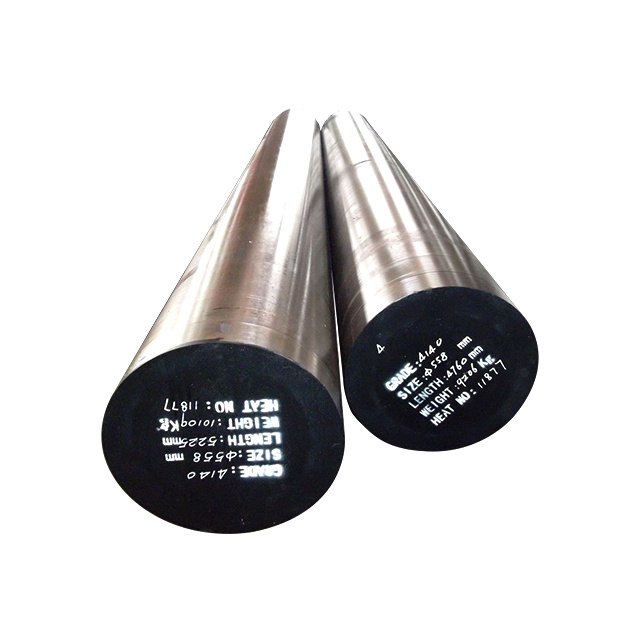

1.7225, SCM440, 42CrMo4, 4140

-

Surface Treatment:

-

black/polished/machined

-

Length:

-

2500~5800mm

-

Tempered:

-

560

-

Forging:

-

1100-900

-

Warranty:

-

MTC / 3.1B

-

Impack work(J/cm2):

-

63

-

Hardness:

-

217HB

-

Certification:

-

ISO9001, SGS, REACH, API

-

Our product line::

-

Tool steel, Carbon structural steel, Alloy structural steel

-

Annual turn over:

-

USD 140,000,000.00

Quick Details

-

Steel Grade:

-

1.7225, SCM440, 42CrMo4, 4140

-

Tolerance:

-

±1%

-

Grade:

-

1.7225, SCM440, 42CrMo4, 4140

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

Neworigin

-

Model Number:

-

1.7225, SCM440, 42CrMo4, 4140

-

Surface Treatment:

-

black/polished/machined

-

Length:

-

2500~5800mm

-

Tempered:

-

560

-

Forging:

-

1100-900

-

Warranty:

-

MTC / 3.1B

-

Impack work(J/cm2):

-

63

-

Hardness:

-

217HB

-

Certification:

-

ISO9001, SGS, REACH, API

-

Our product line::

-

Tool steel, Carbon structural steel, Alloy structural steel

-

Annual turn over:

-

USD 140,000,000.00

General Information:

Chromium molybdenum high tensile steel with yield strength of 550N/mm2.

Chromium renders steel oil hardenable and increase hardenability.

Weldability suffers with increasing chromium content.

High temperature strength and high pressure hydrogenation properties are promoted by chromium and molybdenum.

Molybdenum significantly reduces temper brittleness.

Delivery condition : Hot rolled or forged, Peeled or black surface, annealed or QT.

Comparable Standards:

| AISI/SAE | DIN | W.Nr. | AFNOR | JIS | BS | SIAU | GB,YB |

| 4140 | 42CrMo4 | 1.7225 | 42CD4 | SCM440 | 708A42 | UM8 | 42CrM. |

Chemical Analysis (%):

| C | Mn | Si | Cr | Ni | Mo | P | S |

| 0.38-0.45 | 0.60-0.90 | 0.15-0.40 | - | 0.90-1.20 | - | - | - |

Hot work and Heat treatment temperatures:

| Forging | Normalization | Subcritical annealing | Isothermal annealing | Hardening | Tempering |

| 1100~900 | 860~880 | 680~720 |

830~900

670x3h |

830~860 oil | 550~650 |

Machanical Properties:

| Tensile str. (N/mm2) | Yield point (N/mm2) | Elongation (%) | Contraction (%) | Impack work (J/cm2) | Hardness (HB) |

| 1080 | 930 | 12 | 45 | 63 |

217 |

Take a photo with the client

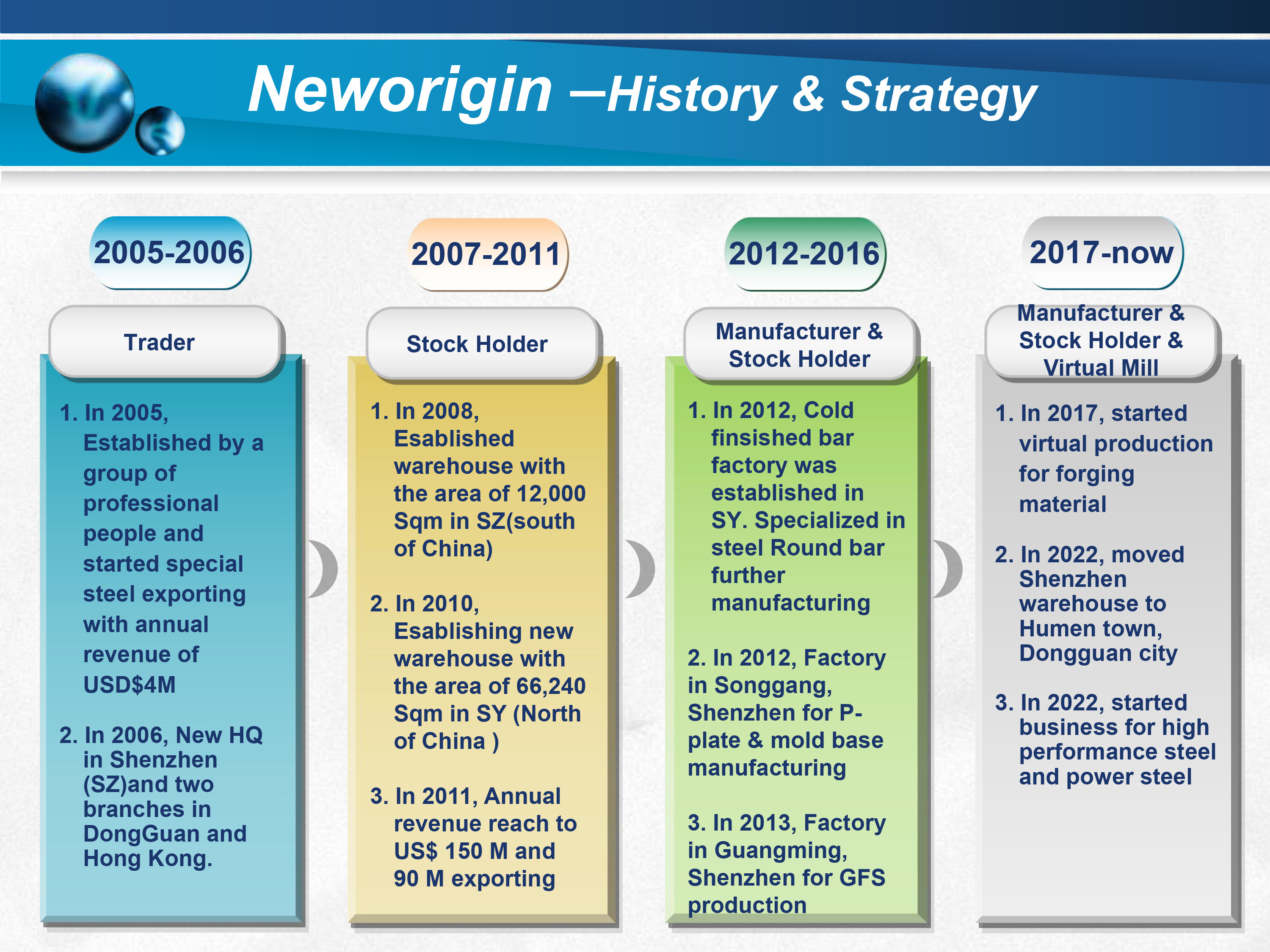

Q1:Are you a factory or trading company?

A:We are a group of mills, forging factories, stockist, exporter & importer, and consultant service provider.

Q2:What kind of products can you provide?

A:Plastic mould steel, hot-work tool steel, cold-work tool steel, alloy structure steel, ground flat stock, P/K plate and etc.

Q3: What's your terms of payment?

A: By T/T, D/A, D/P, O/A and LC.

Q4: What's the terms of delivery?

A: FOB, CFR, CIF,EXW, DAP and etc.

Q5: Could you provide the samples?

A: Yes, we could provide the free samples on condition that it is available in stocks, but the transportation fee is borne by buyer.

Q6: How could you guarantee the quality?

A:(1): We strictly-select domestic famous special steel mills and achieved a long-term stable cooperation relationship.

(2): Equipped with melting grade inspection instruments; Supported by certified professional inspectors and technical team.

(3): Strict IQC, IPQC, OQC; Reasonable warranty terms; Promise for "Decuple Penalty for Fake".