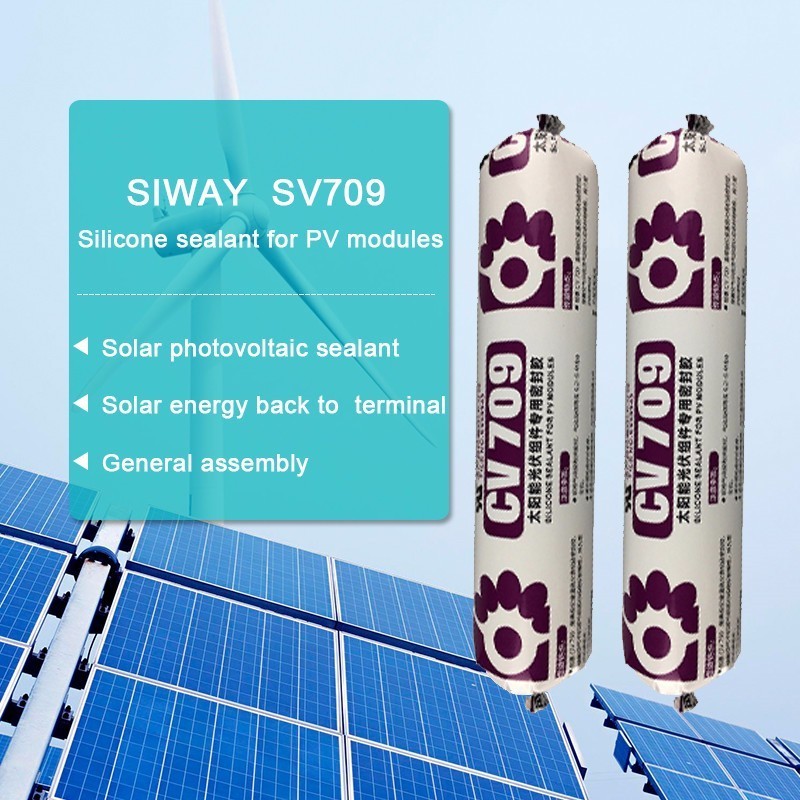

- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Siway

-

Model Number:

-

SV 709

-

Type:

-

One Component, one-component silicone sealant

-

Color:

-

White/Black/Grey

-

Application:

-

solar module

-

Product name:

-

solar panels silicone sealant

-

Keywords:

-

solar module sealant

-

Package:

-

300ml/400ml

-

Viscosity:

-

Strong

-

Certificate:

-

JCJ

-

Shelf life:

-

12 Months

-

Quality:

-

100%silicone

Quick Details

-

CAS No.:

-

7085-85-0

-

Other Names:

-

Solar module sealant

-

MF:

-

Mixture

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Siway

-

Model Number:

-

SV 709

-

Type:

-

One Component, one-component silicone sealant

-

Color:

-

White/Black/Grey

-

Application:

-

solar module

-

Product name:

-

solar panels silicone sealant

-

Keywords:

-

solar module sealant

-

Package:

-

300ml/400ml

-

Viscosity:

-

Strong

-

Certificate:

-

JCJ

-

Shelf life:

-

12 Months

-

Quality:

-

100%silicone

How to Identify the Quality of Silicone Sealant?

Stretch to the limit to see if there are cracks and breaks? Rebound is not as ever?

High-quality silicone sealant tensile strength, tensile strength, anti-peel strength. Silicone sealant hardness and elasticity is moderate, too hard or too soft silicone sealant are not good silicone sealant

SV 709 is oxime type curing, one component,strong mechanical performance after curing. It has fast skin forming time and easy-to-use. SV 709 has already been successfully applied in solar industy. It can make skin formed in a few minutes and achieve enough mechanical property to meet the requirement of the solar production line. After cured, SV 709 can provide long-term protection to solar power.

Advantage

1. good sealing, the aluminum, glass, TPT / TPE back material, junction box plastic PPO / PA have good adhesion;

2. a unique curing system, measured by high temperature and humidity ring, with all types of EVA have good compatibility;

3. the unique rheological system, the colloid of the fine, good resistance to deformation ability;

4. flame retardant performance to UL 94-V0 the highest level;

5. in full compliance with the EU ROHS environmental directive requirements, SGS-related test reports.

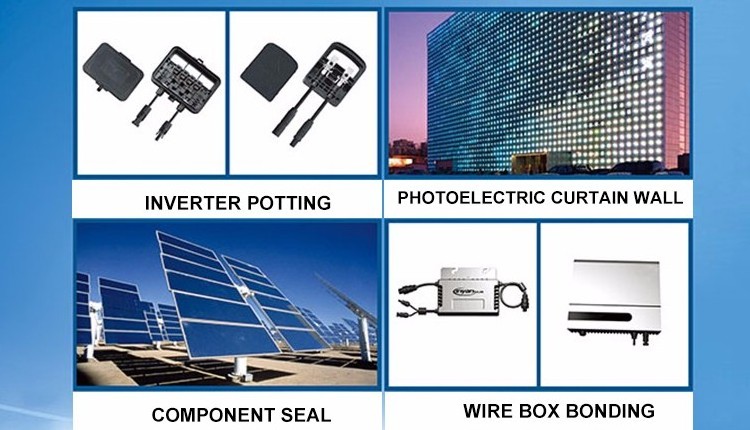

6.Typical applications: Solar panel bonding, PV module aluminum frame sealing and junction box and TPT / TPE back film adhesive seal.

Parameters

|

Test Item

|

Unit

|

Result

|

||

|

Mechanical Properties after Cure

|

|

|

||

|

Density

|

g/ml

|

1.41

|

||

|

Tensile strength

|

Mpa

|

2.7

|

||

|

Elongation

|

%

|

550

|

||

|

Hardness, shore A

|

point

|

35

|

||

|

Lap shear (AI/AI) unprimed adhesion

|

Mpa

|

1.8

|

||

|

Electronic Properties after Cure

|

|

|

||

|

Dielectric strength

|

KV/mm

|

22

|

||

|

Volume resistivity

|

Ohm,cm

|

10E14

|

||

|

Dielectric constant

|

@50HZ

|

3.2

|

||

|

Dissipation factor

|

@50HZ

|

0.0031

|

||

|

After aged under 85℃&85%RH for 2000hours

|

|

|

||

|

Tensile strength

|

Mpa

|

1.8

|

||

|

Elongation

|

%

|

370

|

||

|

Hardness, shore A

|

point

|

40

|

||

|

*******Test condition :23±2℃,50±2%RH******

|

|

|

||

|

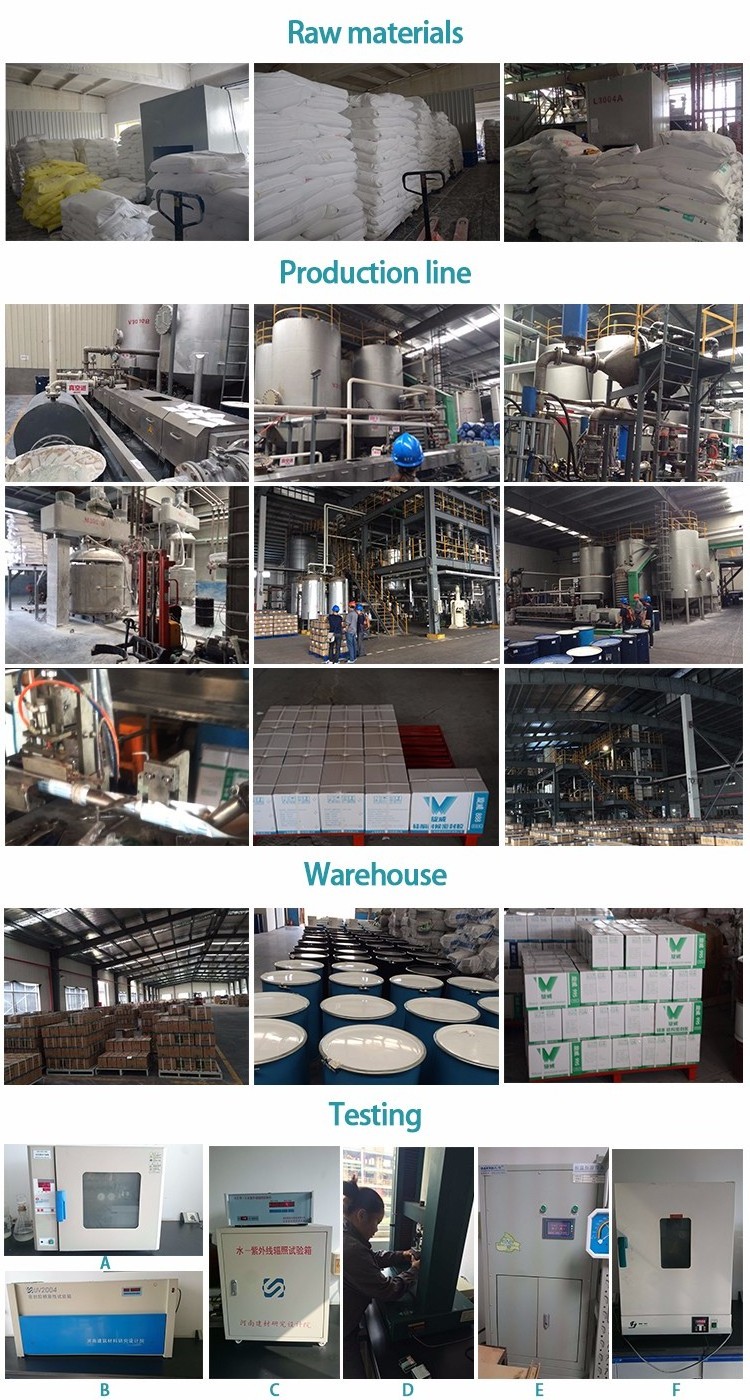

Testing A

|

Equipment Name

|

Electric thermostaticdrying oven

|

|

|

||

|

|

Testing purposes

|

Test the volatilization of silicone sealant materials and silicone sealant products

|

|

|

||

|

Testing B

|

Equipment Name

|

Sealant Compatibility Test Chamber

|

|

|

||

|

|

Testing purposes

|

Test the adhesion of the silicone sealant to the substrate

|

|

|

||

|

Testing C

|

Equipment Name

|

UV weathering test machine

|

|

|

||

|

|

Testing purposes

|

Test the weather resistance of silicone sealants in simulated natural environments

|

|

|

||

|

Testing D

|

Equipment Name

|

Tensile testing machine

|

|

|

||

|

|

Testing purposes

|

Detection of tensile strength of sealant adhesive, bond failure area, the maximum tensile strength at a certain temperature elongation

|

|

|

||

|

Testing E

|

Equipment Name

|

constant temperature and humidity device

|

|

|

|

|

Testing purposes

|

Test the weather resistance of silicone sealant

|

|

|

|

Testing F

|

Equipment Name

|

high temperature oven

|

|

|

|

|

Testing purposes

|

This experiment simulates the high-temperature environment, accelerates the thermal oxidation of the sealant in the air, so as to determine the high-temperature aging resistance of the sealant

|

|

|

Our factory is located in Quzhou, Zhejiang High-tech Industrial Park, covers an area of 330 acres, more than 500 employees, including college education more than 200 people, we are new fluorine-silicon industry in Zhejiang Province technological innovation pilot units.

WELCOME TO VISIT US --- SIWAY

Big smile on Majesties face. Silicone sealant in your home, Money rushes to you.

More Professional, More Patient, More Responsibility.

Our Siway team always try our best to help all of you.