- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

STA

-

Name:

-

alumina ceramic pipe

-

Shape:

-

Rod/Tube/Sleeve/Roller/Bushing

-

Color:

-

Ivory White Yellow Pink

-

Alumina Content:

-

85% 90% 95% 99% 99.7%

-

Max. working temperature:

-

1800C

-

composition:

-

mullite-corundum

-

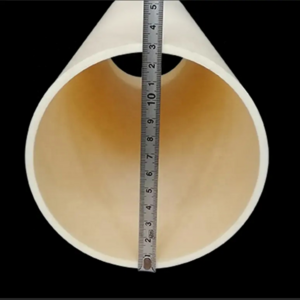

Size:

-

OD.20mm to 70mm or according to customer request

-

Bore:

-

single,double,four,multi

-

thickness:

-

5~6.5mm or customized

-

End:

-

Open Both Ends or Closed One End

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Henan, China

-

Model Number:

-

STA-AL2O3-49

-

Brand Name:

-

STA

-

Name:

-

alumina ceramic pipe

-

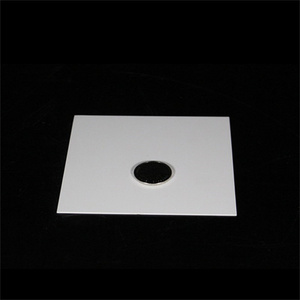

Shape:

-

Rod/Tube/Sleeve/Roller/Bushing

-

Color:

-

Ivory White Yellow Pink

-

Alumina Content:

-

85% 90% 95% 99% 99.7%

-

Max. working temperature:

-

1800C

-

composition:

-

mullite-corundum

-

Size:

-

OD.20mm to 70mm or according to customer request

-

Bore:

-

single,double,four,multi

-

thickness:

-

5~6.5mm or customized

-

End:

-

Open Both Ends or Closed One End

STA large diameter aluminium oxide alumina ceramic tube for casting

Specification

1. alumina porcelain pipe

2.Max working temperature 1800

3. High Purity 99.7%

4. Excellent Insulation

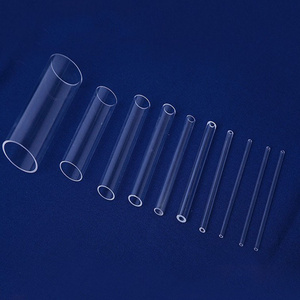

Thermocouple protective tube 99% alumina al2o3 ceramic tubes

The Al2O3 ceramic tube are constructed of pure 99.7% Al2O3 that has superior gas and vacuum tightness and excellent insulating properties even at elevated temperatures. The alumina ceramic tube/rod/bar is an ideal wear-resistance material for delivering the sand, mine, ash dregs and molten aluminium, has excellent conductivity, high machinery strength and high temperature resistance, can resist to the acid, high temperature, corrosion and static electricity. Al2O3 is the most important technical ceramic material. It is characterized by high hardness, high compressive strength and corrosion resistance even at high temperatures. Through the content of Al2O3 in the material,these properties can be tailored to the application of customer. Other material like Mullite, Zirconia, Silicon Carbide, Silicon Nitride bonded Silicon Carbide is also available.

Features of Al2O3 ceramic tube

1. High quality: Max working temperature 1800C, high abrasive resistance.

2. Various sizes for your choose, diameter from 1-120mm, length from 10-2000mm

3. Various processing methods make right tubes for different usage, including extruding, casting, pressing etc.

4. Tubes can be grinding, drilling holes etc according to the requirements of customers.

5.Stiffness texture.

6. Large quantity in stock can provide fast delivery and very competitive prices.

Main performance index of Al2O3 ceramic tube

| performance index | Measuring unit | High purity alumina | Alumina | High alumina |

| Al2O3 | % | 99.7 | 99.3 | 85 |

| SiO2 | % | less than0.1 | — | — |

| Density | g/cm3 | 3.95 | 3.88 | 3.2 |

| Water absorption | % | 0 | 0.01 | 0.2 |

| Cld compressive strength | Mpa | 450 | 350 | 200 |

| 20 degree Celsius leak rates | Torr/L.sec | less than10-11 | less than10-11 | less than10-11 |

| Twisting in high temperature | mm | 1700 degree Celsius 0.2 allowance | 1600 degree Celsius 0.2 allowance | 1400 degree Celsius 0.2 allowance |

| Bonding in high temperature | 1700 degree Celsius non-caked | 1600 degree Celsius non-caked | 1400 degree Celsius non-caked | |

|

20—1000 degree Celsius coefficient of

thermal expansion |

mm.10-6/degree Celsius.m | 8.6 | 8.2 | 8.2 |

| Thermal conductivity | W/m.k | 25 | 25 | 25 |

| Electric insulation strength | KV/mm | 20 | 20 | 15 |

|

20 degree Celsius direct current

insulating resistance |

Ohm/cm | 10 14 | 10 14 | 10 14 |

|

High-temperature

insulation resistance |

1000 degree Celsius MΩ | ≥0.08 | ≥0.08 | ≥0.08 |

| 1300 degree Celsius MΩ | ≥0.02 | ≥0.02 | ≥0.02 | |

| Thermal shock resistance | 1550 degree Celsius 6 times not cracked | 1550 degree Celsius 6 times not cracked | 1300 degree Celsius 3 times not cracked | |

| Maximum service temperature | degree Celsius | 1900 | 1800 | 1400 |

alumina ceramic tube, alumina porcelain pipe

Alumina or Aluminium Oxide(Al 2 O 3 ) in its various of levels of purity is used more often than any other types of advanced ceramic materials. Alumina cermaic is a kind of structural ceramics, with insulation resistance, voltage resistance, high strength, good thermal conductivity, dielectric loss, stable electrical performance characteristics. Used in electronic ceramic substrates, ceramic electrical insulation, vacuum devices, spark plugs etc.

Why Choose STA

1. Your inquiry related to our products or prices will be replied within 24hours.

2. Well-trained and experienced staffs to answer all your inquiries in fluent English.

3. All our products have 1-year warranties.

4. Offering the support to solve the problem in the application or selling period.

5. Competitive prices based on same quality.

6. Guarantee samples quality same as mass production quality.