- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

DS-180A

-

Certificate:

-

ISO9001

-

Weight:

-

180kg

-

Speed:

-

6m/min

-

Applicable cable diameter:

-

60-180mm

-

Product name:

-

Cable conveyor cable feeding equipment for underground cable laying

-

Color:

-

Customized

-

Application:

-

Power construction for underground cable laying

-

Warranty:

-

One year

-

After-sale service:

-

Engineers available to service machinery overseas

-

Electric motor:

-

1.5KWx2

Quick Details

-

Use:

-

For laying power cable

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Haoxin

-

Model Number:

-

DS-180A

-

Certificate:

-

ISO9001

-

Weight:

-

180kg

-

Speed:

-

6m/min

-

Applicable cable diameter:

-

60-180mm

-

Product name:

-

Cable conveyor cable feeding equipment for underground cable laying

-

Color:

-

Customized

-

Application:

-

Power construction for underground cable laying

-

Warranty:

-

One year

-

After-sale service:

-

Engineers available to service machinery overseas

-

Electric motor:

-

1.5KWx2

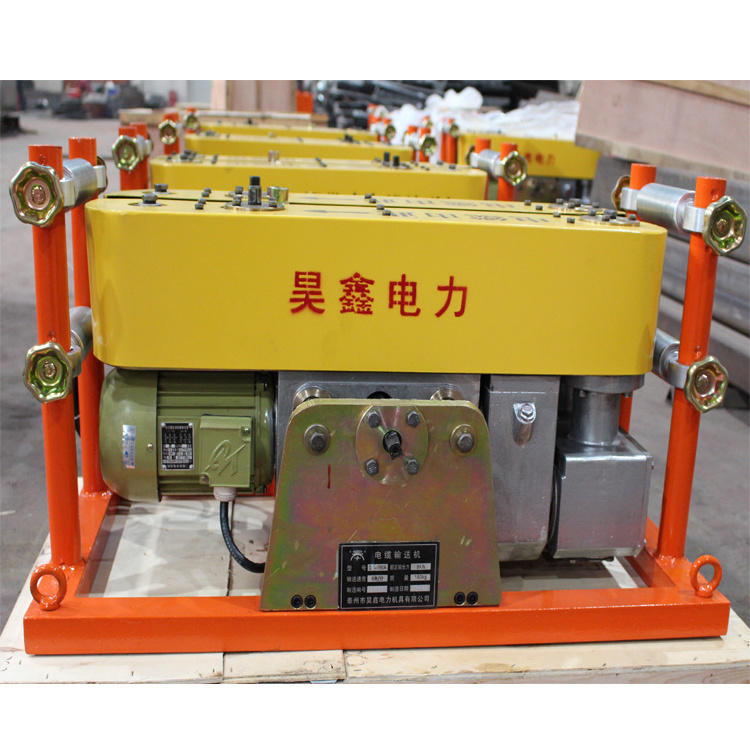

Good quality cable conveyor cable automatic feeding equipment for underground cable laying

Description:

Description:

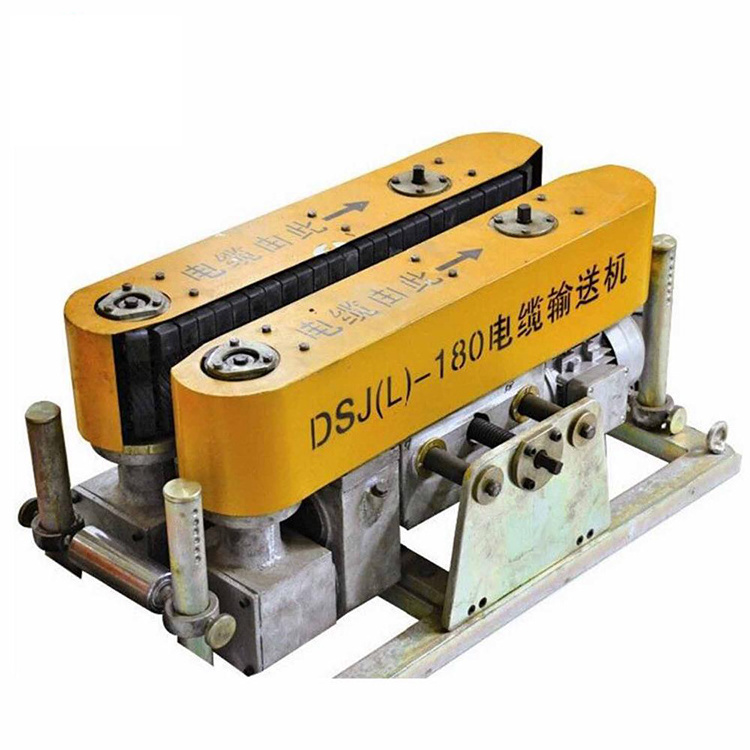

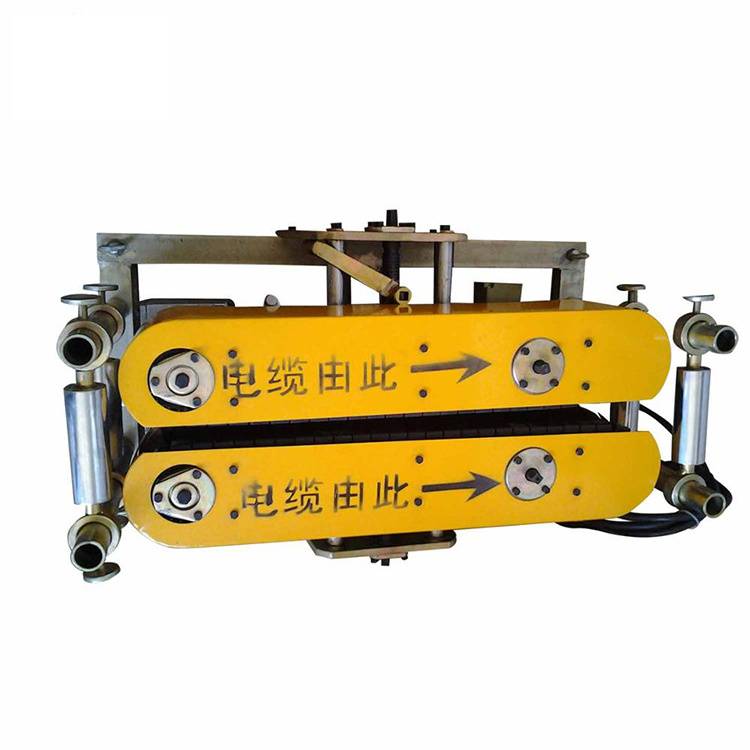

Ds-180A crawler cable conveyor is suitable for large-scale urban power grid reconstruction, large section and long-distance cable laying, reducing labor intensity and improving construction quality. The machine has the advantages of large displacement, small volume, light weight and convenient operation. It is especially suitable for long-distance laying such as cable laying, tunnel and direct burial.

Features :

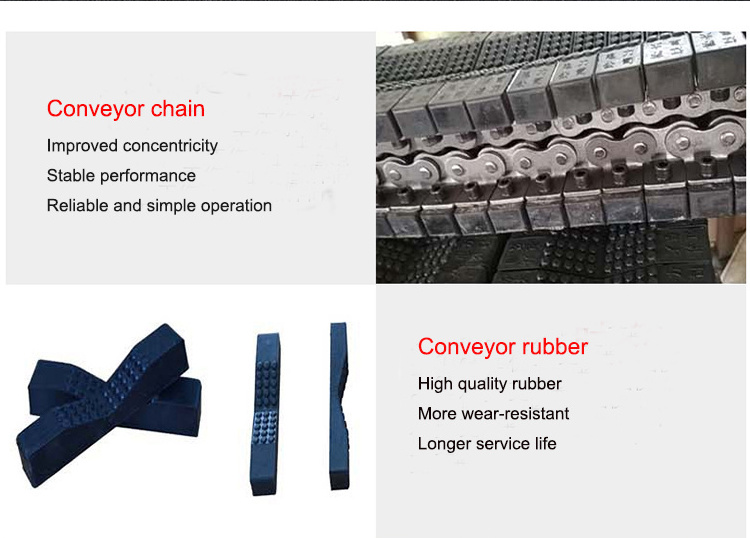

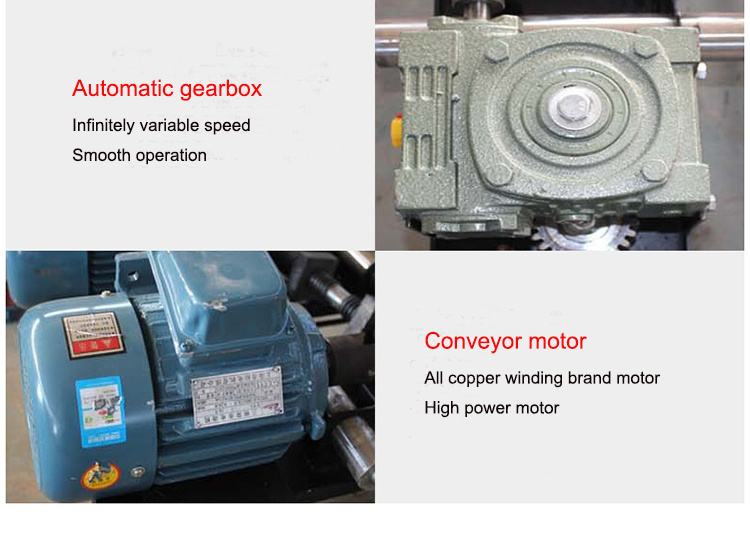

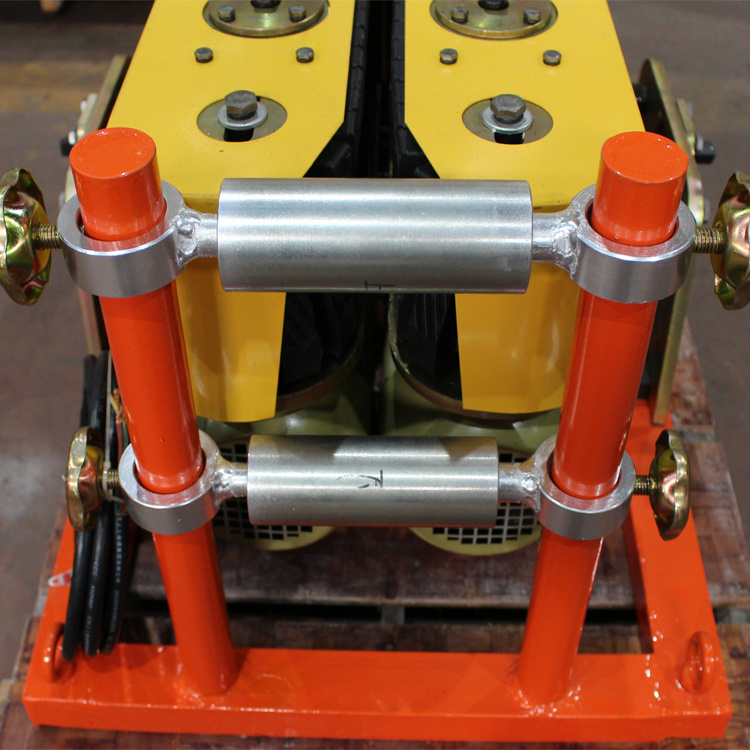

1. The conveyor is mainly composed of frame, motor, speed box, bracket, sliding seat and other components. There is a clamping mechanism in the sliding seat to ensure that the track of the cable is close to the cable in the transmission process, which greatly improves the transmission force.

2. All products are modular design, totally closed structure, easy to maintain, good dust-proof effect, simple and compact structure.

3. The motor power is 1. 1kW adopts conveying driving mechanism, which has the characteristics of high power and high efficiency.

4. The sliding box has a spring pressing mechanism, which has a good protection effect on the cable.

Construction method:

1. Install the cable conveyor in a suitable workplace.

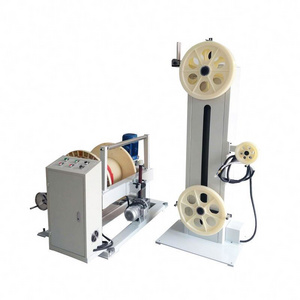

2. Install the cable on the cable car in the cable conveyor through the cable guide frame, cable net sleeve, rotary connector, etc.

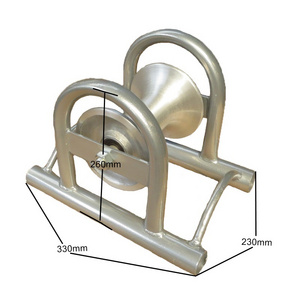

3. Install the steering pulley and cable pulley in the proper path of cable passing. Pipe mouth protective cover, protective wheel, etc.

4. The cable is driven by the cable tractor to run.

5. It must be noted that the cable puller must be synchronized with the speed of the cable conveyor.

Good quality cable conveyor cable automatic feeding equipment for underground cable laying

| Model | Pulling speed | Applicable cable diameter | Conveying force | Dimension | Weight | Electric motor |

| DS-180A | No use frequency control valve: 6m/min Use frequency control valve: 0~15m/min | Φ60-180mm | 8kN | 940x460x380mm | 180kg | 1.5Wx2 |

Contact me and " SEND " inquiry if you are interested in it.